Morph+

Form Active Structures

Can the integration of bioplastics onto tensile fabrics create a material system which is geometrically responsive to build a self-deployable, lightweight, low-cost and easily transportable structures?

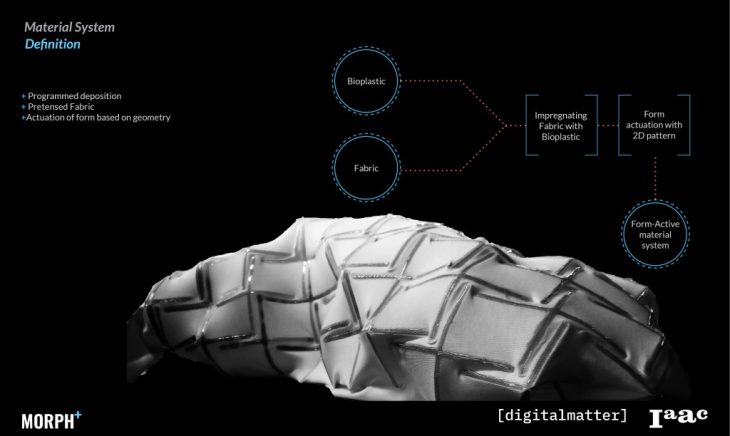

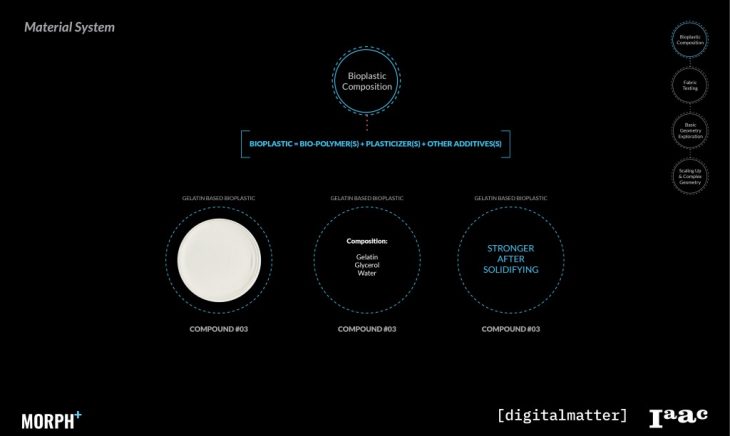

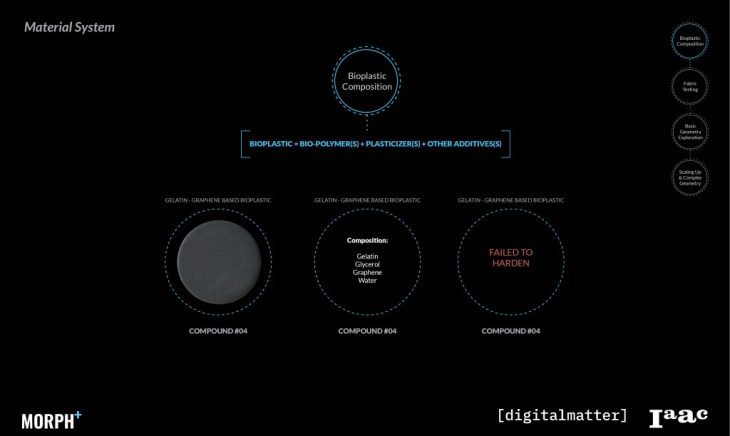

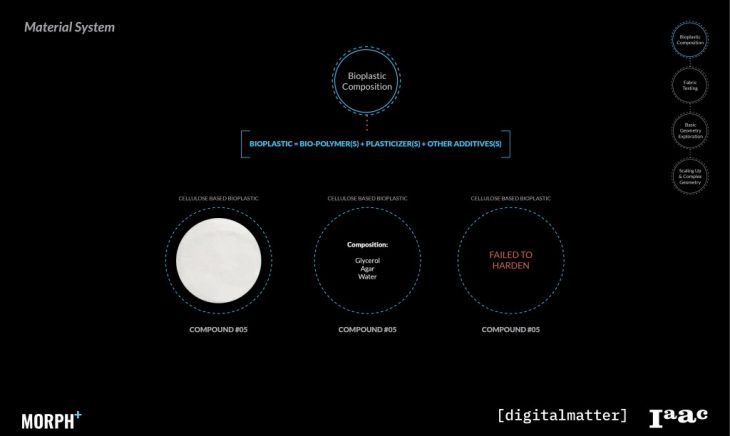

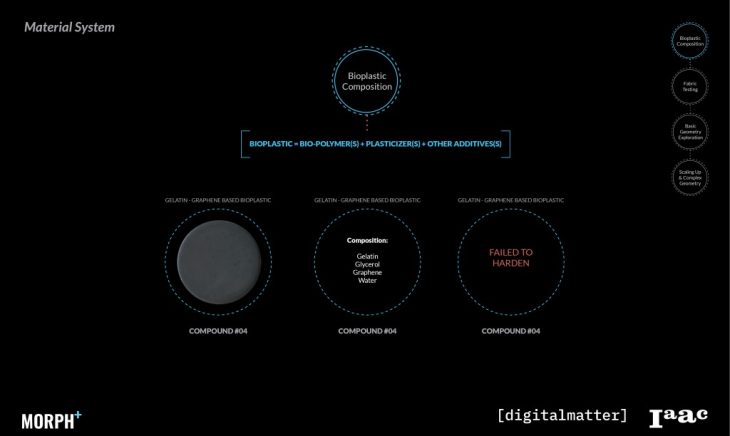

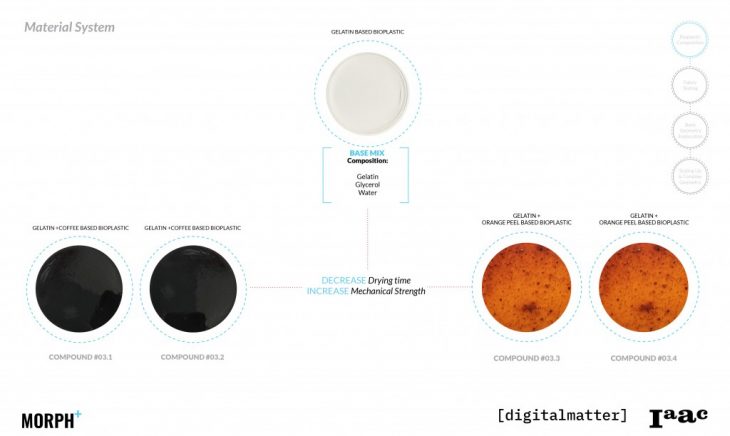

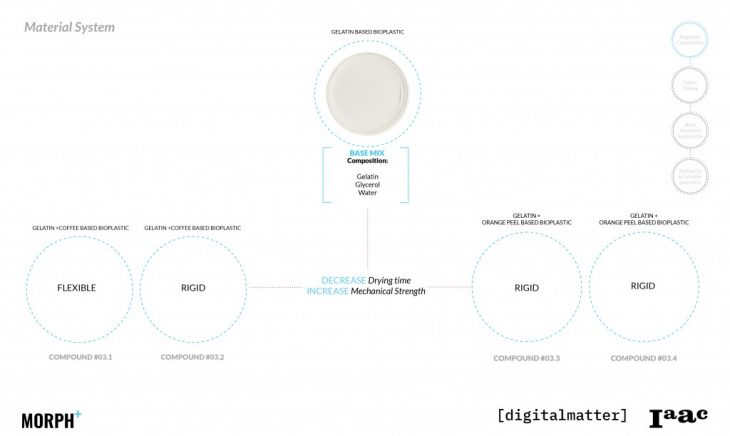

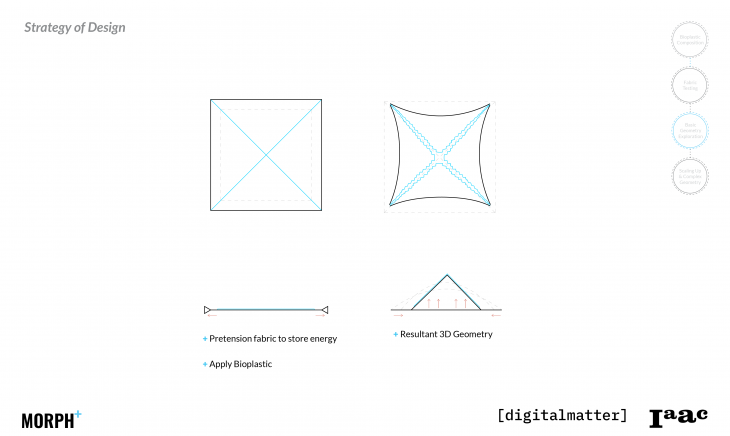

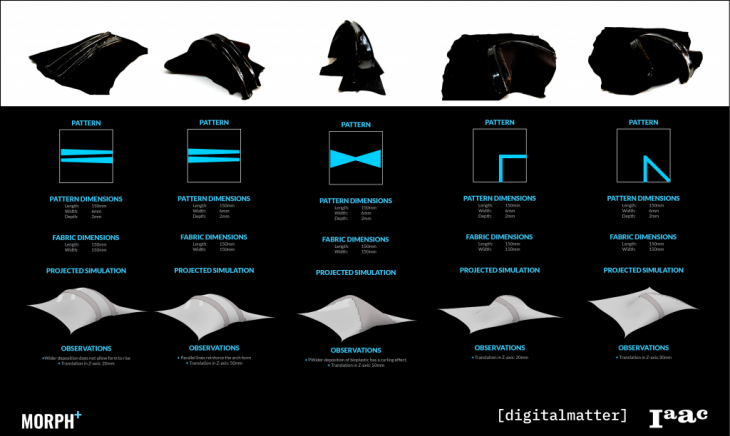

With the core aim to develop a responsive material system, the project explores the design of a material system that is receptive to its geometry and fabrication process. The two main components of the material include are – a highly elastic fabric and a stiffening agent such as the bioplastic. The actuation of the entire material system is embedded in the geometry.

The material system consists of a programmed deposition of bioplastic material on a highly elastic fabric in tension. The bioplastic acts as a stiffening agent on the fabric. On releasing the fabric from tension, it morphs into a three-dimensional form corresponding to the material deposition.

STRATEGY OF DESIGN: SIMULATION

Simulation

STRATEGY OF DESIGN: FABRICATION

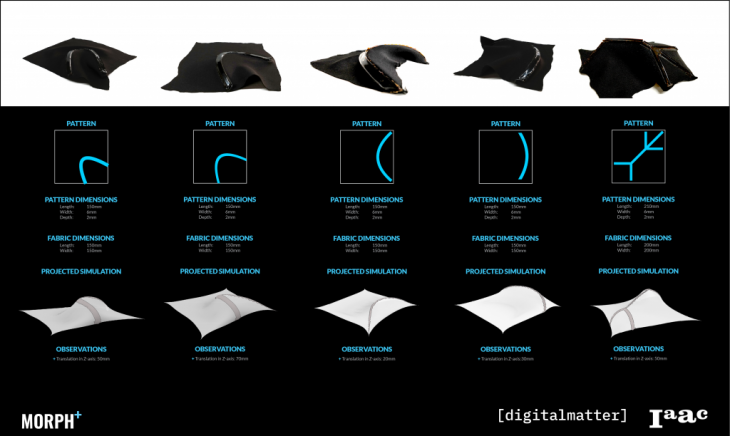

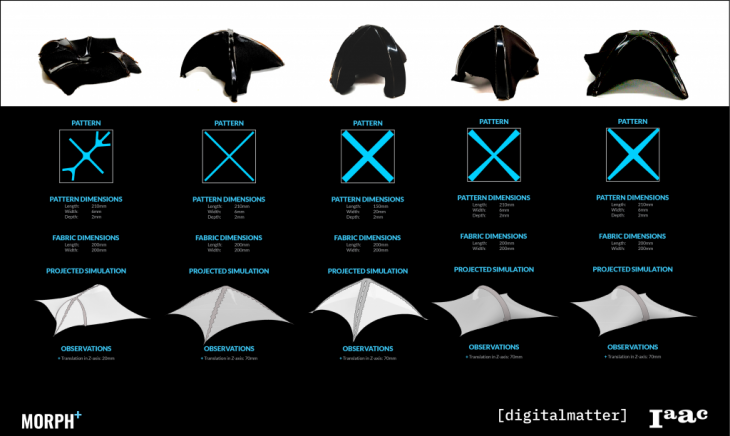

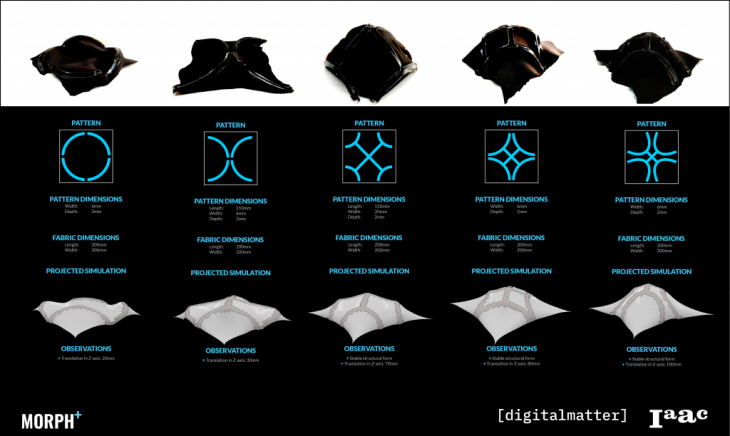

GEOMETRY CATALOGUE

SCALING UP PARAMETERS

A) Original Module

Geometry

Simulation

B) Multiply

Geometry

Simulation

C) Staggering

Geometry

Simulation

D) Differential Scaling

Geometry

Simulation

E) Scaling up the single module

Geometry

Simulation

F) Spacing

Geometry

Simulation

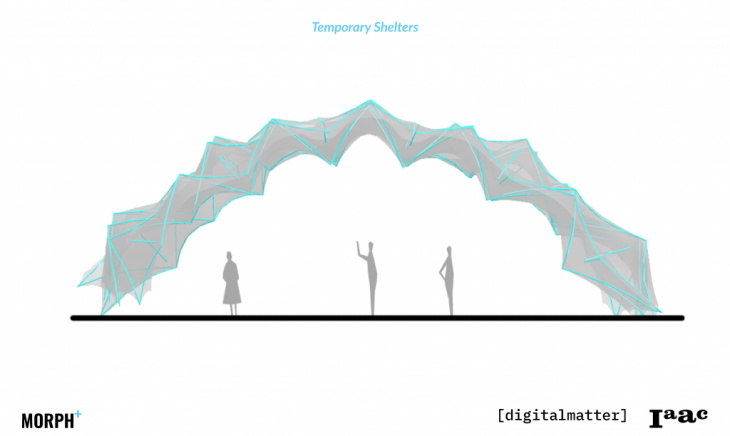

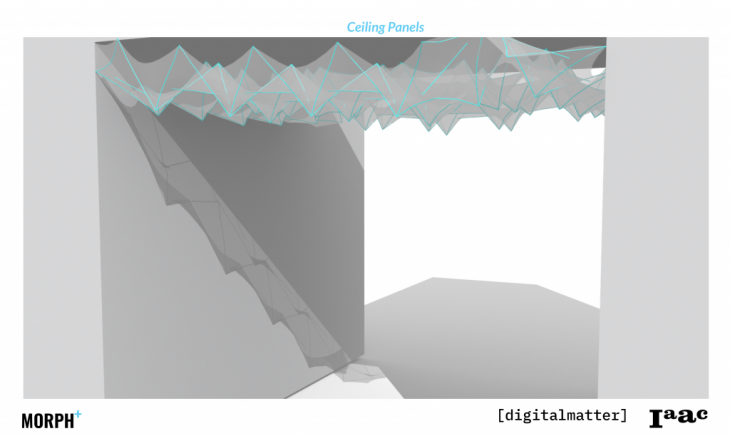

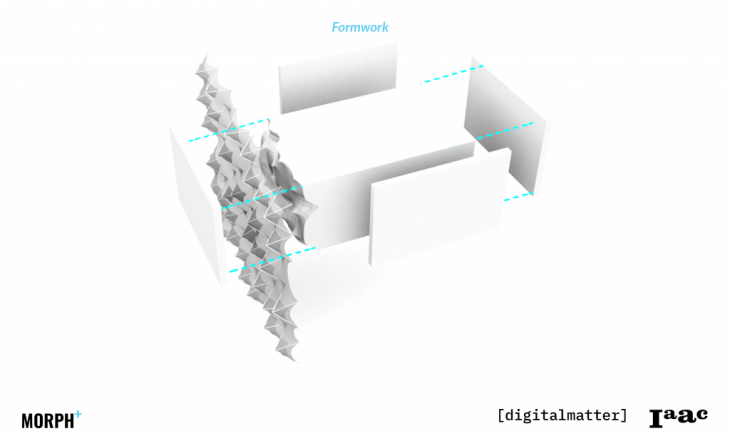

COMPLEX GEOMETRIES

APPLICATIONS

Morph+ is a project of IaaC, Institute for Advanced Architecture of Catalonia

developed at MAA01 in 2017 by:

Student: Bhakti Vinod Loonawat and Ipsita Datta

Lead Faculty: Areti Markopoulou

Faculty Assistants: David Andrés León, Raimund Krenmüller

Computational Advisor: Angelos Chronis

In collaboration with IIT, IIT, the Italian Institute of Technology and the Smart Materials Group

IT Material Experts: Athanassia Athanassiou, Ilker Bayer, Giovanni Perotto, Material Scientist