Concept:

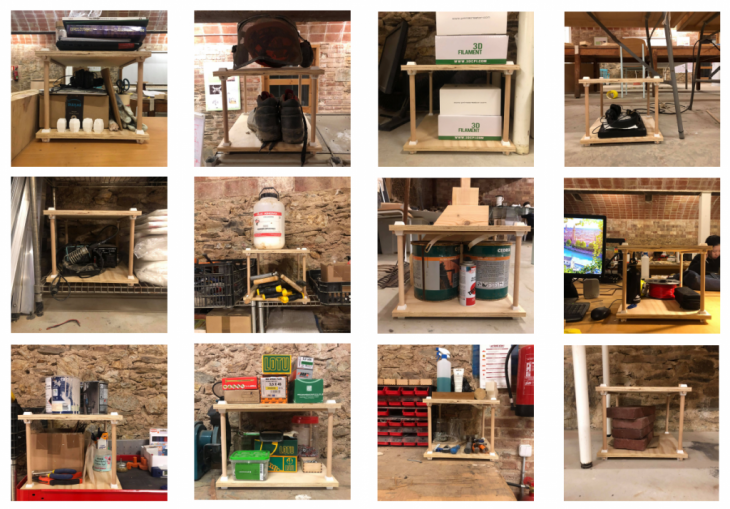

Initial goal was to have a repeatable unit that can serve as an organizing system for Fab / Lab tools. Therefore creating a modulor system. This units main material is wood, therefore promoting ecological use of it on laboratories. Its flexibility of construction opens room for achieving different spans based on personal requirements. On this picture we can see a variety of usage of the modulor, the top part is of higher length to store books, where as the 2 bottom are made of shorter dowels to hold smaller objects.

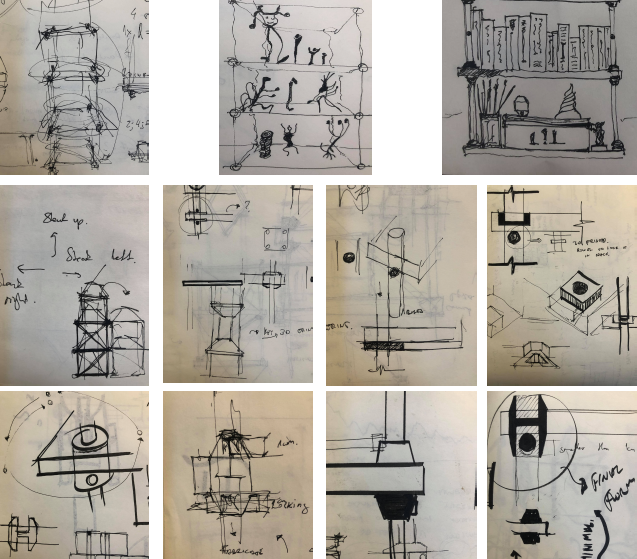

Concept sketches:

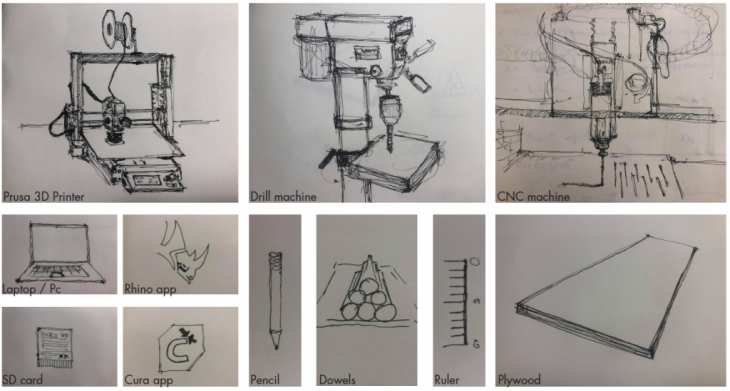

Digital Fabrication tools:

3D Printer; drilling machine; CNC; Rhino application; Ultimaker Cura application; micro SD card; laptop / PC; dowels; pen / pencil; ruler; plywood board; PLA 3D printing material. Materials used for the creation of the modulor.

Material amount / dimensions:

4x Plywood boards 350x400mm

12x 3D printed joinery

8x 250mm dowels; d=15mm

6x 400mm dowels; d=10mm

1x Rhino application; Cura application; pencil; ruler; laptop; SD card;

1x PLA 3D print material

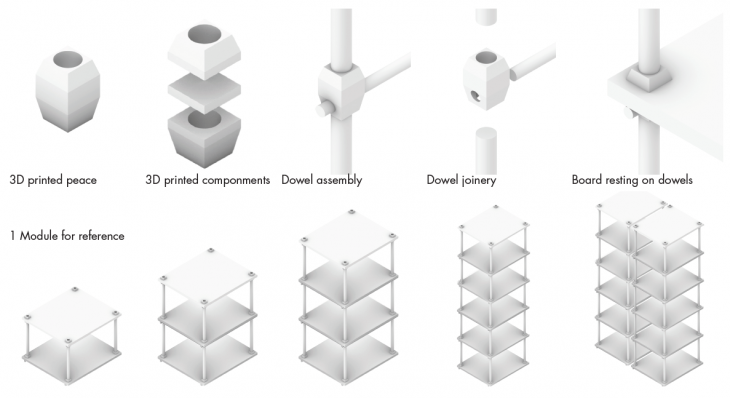

Assembly axonometric of the modulor:

From the 3D printed peace to the dowel system; These Axo drawings demonstrate assembly of one modulor, where as the 2nd row showcases the variety of stacking system with the so created module.

Fabrication:

The fabrication process consists of using the CNC machine with a 6mm endmill to drill the holes and cut the boards. In the mean time 3D printer is used for the fabrication of PLA joineries that are later used as connection points. Where as the dowels are taken to the drill opening machine to create the 10mm in diameter openings that supports the weight of the module. This type of assembly can be repeated through out the process depending on the necessity for storage space.

Assembly:

Examples of modulor:

Credits:

Modulor is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Ecological Buildings and Biocities in 2020/21 by students: Engjëll Rodiqi, and faculty: Eduardo Chamorro