Intro to Digital Fabrication_MaCT, IaaC, 2016/17

a course of Djordje Stanojevic, Tutor: Kunal Chadha, Student: Federica Ciccone

Submission 01

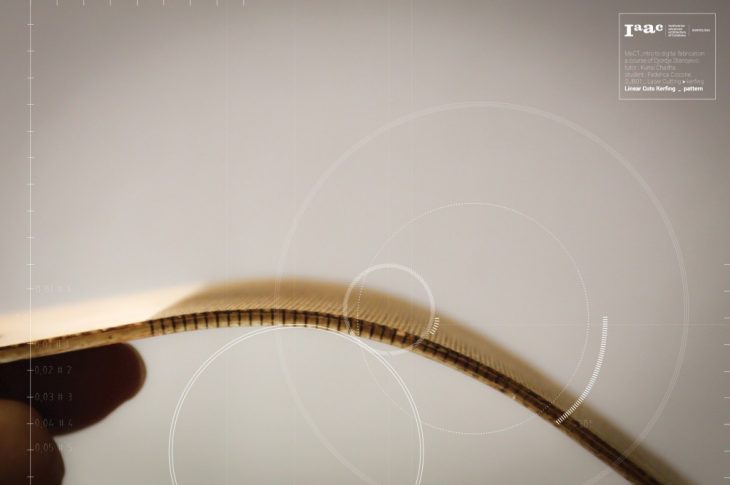

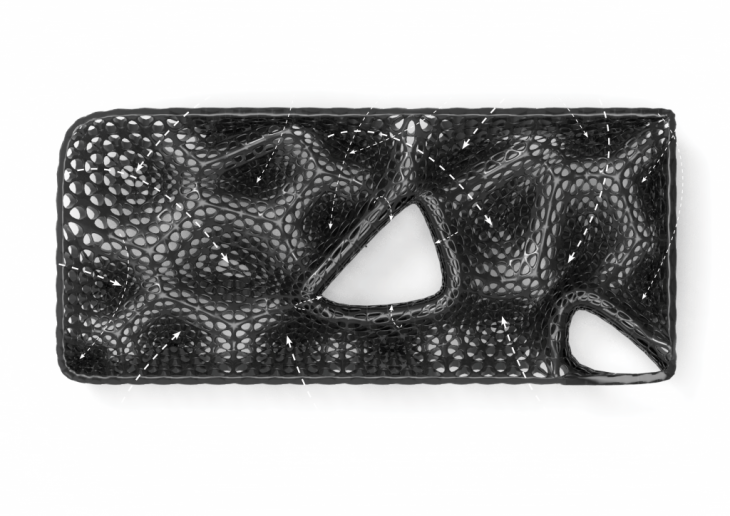

Linear Cuts Kerfing_pattern

DATA

Material: foil of wood

Technique: laser cutting

CONCEPT

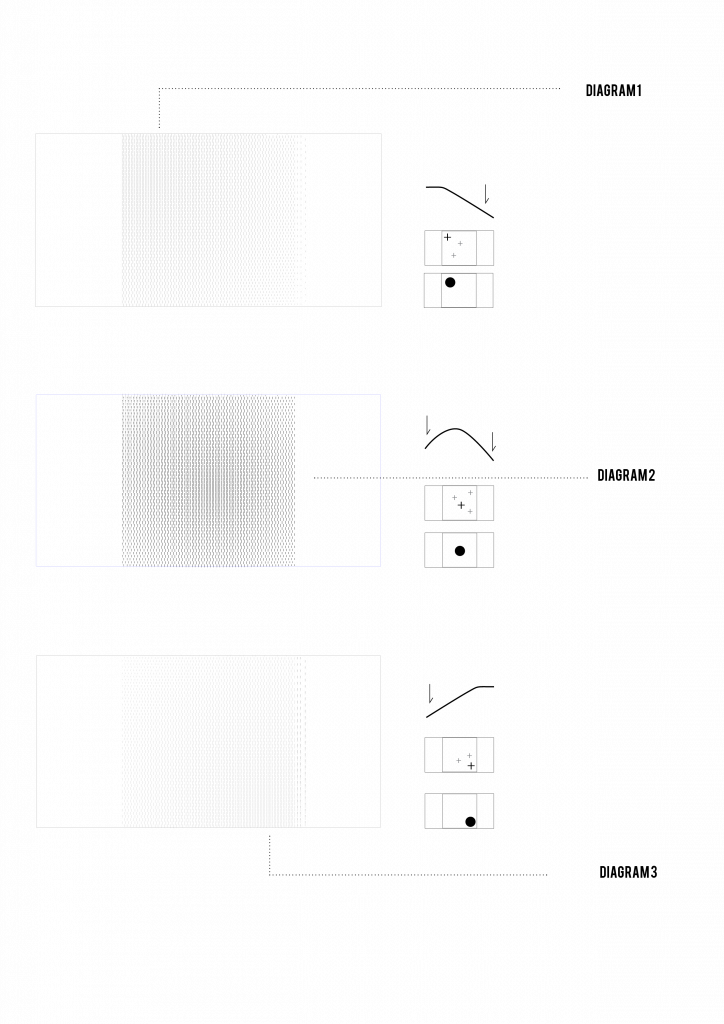

The concept of this proposal is to work with a microperforations_pattern , or better “micro-cuts pattern”, on a wooden panel (x, y) tryng to improve the flexibility of this surface, through an assial cut of the wooden material focus of the research.

————————————————————————————————————————-

The used method, was the kerfing one, applied on the panel in exam through the use of laser cutting.

In order to achieve the goal of the “material performances’ improving”, work has been done on the surface through a simple linear pattern, composed by a sequences of micro-perforations of the same.

The weaving of this pattern is connected and enhanced using an attractor point, able to crate an intensification of the cuts, in relation with their mutual position with this one, which is considered as a polarity.

In this way is created a variable puncture-pattern that underlined, in the different runs performed, the ability to confer, to the foil of wood in exam, a considerable addition of flexibility, comparable to more than 30% of its normal resistance condition.

Working evenly and on the entire surface even though with different intensity; has emerged as distributed holes’ density breaking the axial structure of the plot in question, can be able to transform the rigid nature of the material’s surface in a flexible one, adaptable to various new performances.

Thinking about this, in a larger scale, could be able to become an example of use’s possibilities of the material, also subject to such curvatures in relation to the clumping of the plot.

(as seen from the attached diagrams and images)

————————————————————————————————————————-

Submission 02

Milled_pattern

DATA

Material: foam

Technique: CNC Milling

CONCEPT

The concept of this second exercise is to design and prototipy

This project aims to create a cast object by creating the mold in using the potential of the CNC milling and digital technologies.

————————————————————————————————————————-

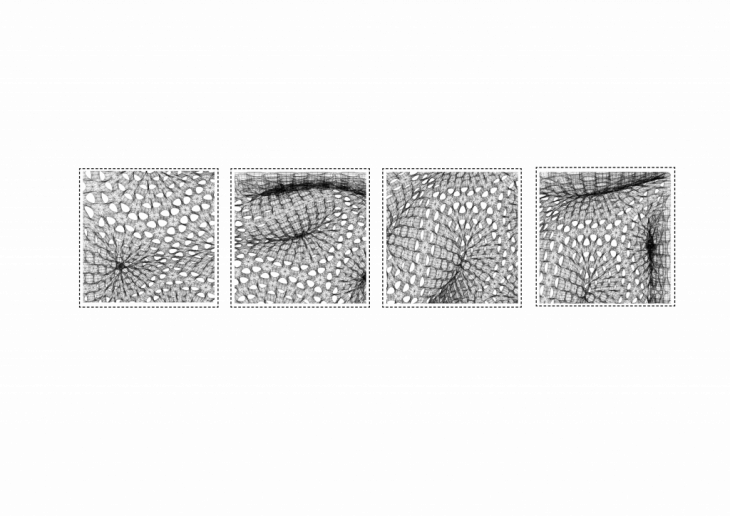

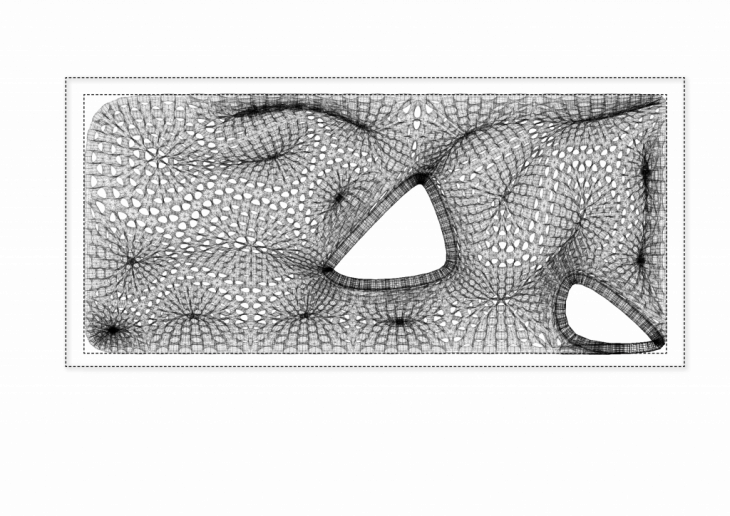

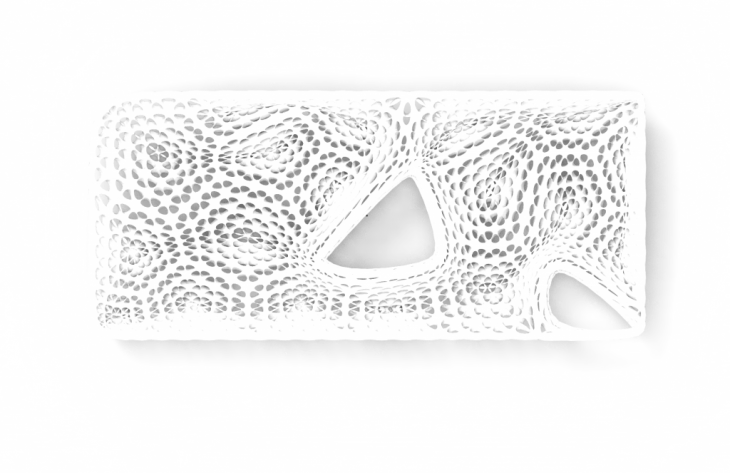

Voronoic surface + multiple points’ attraction influence

Voronoic Surface representation

Modelled surface

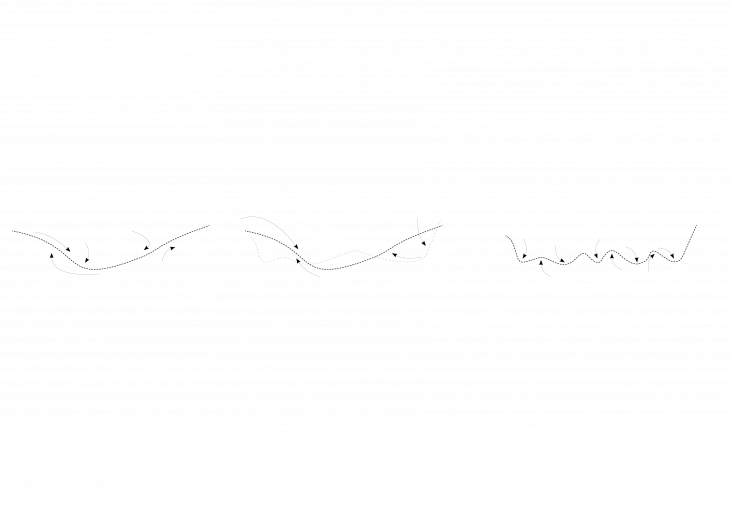

Diagramatic representation of active forces’ influence on the surface

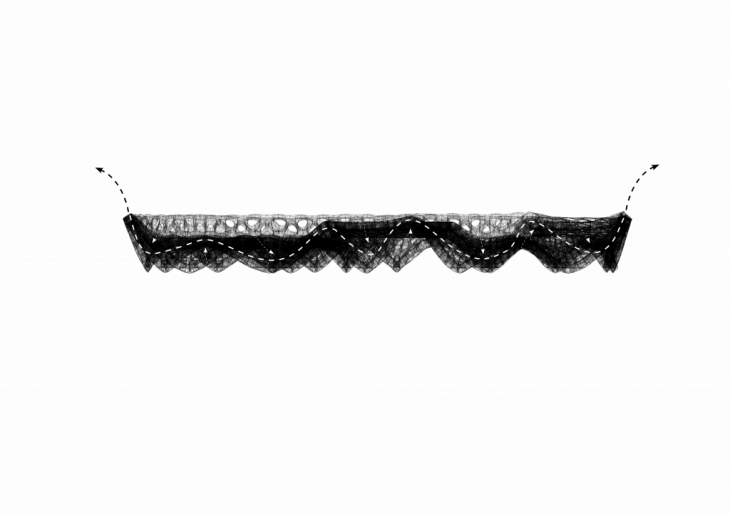

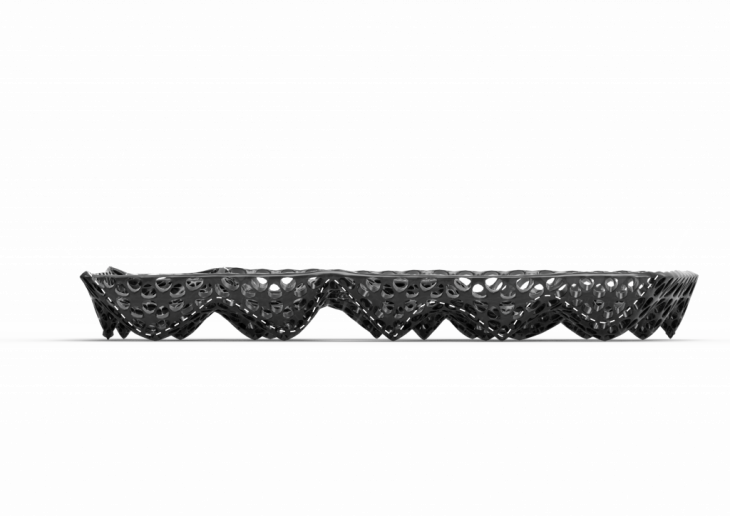

Surface’s section analysis

Modelled Milled Surface’s representation_top and section view

Modelled Milled Surface’s representation_top and section view

————————————————————————————————————————-

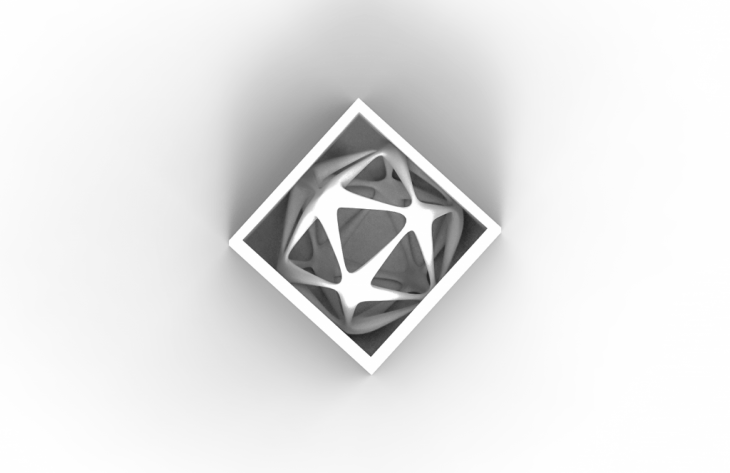

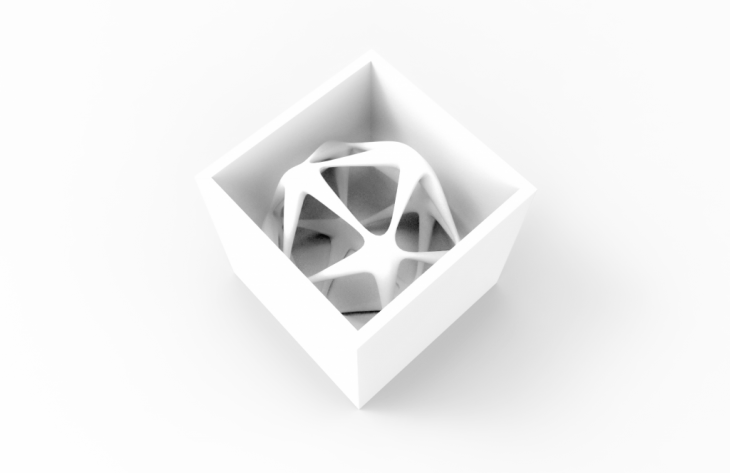

Submission 03

DATA Material: PVA and Resin Casting Technique: 3d Printing

CONCEPT

This project aims to design a cast object by creating the moled in using the potential of the 3D print and digital technologies.

————————————————————————————————————————-

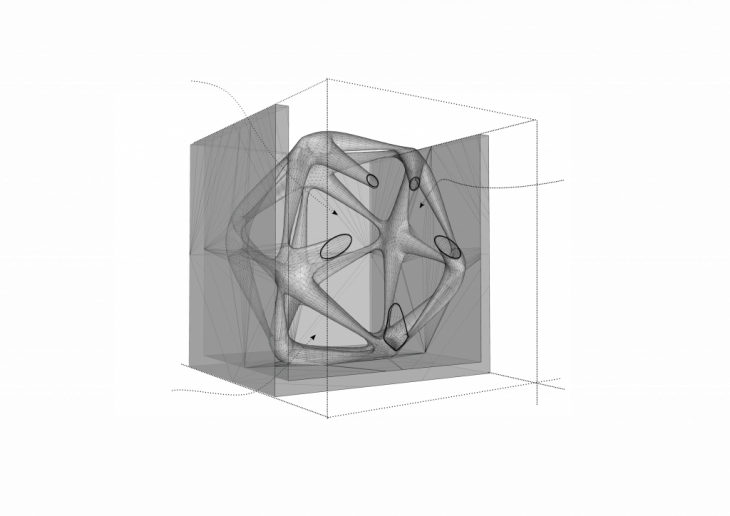

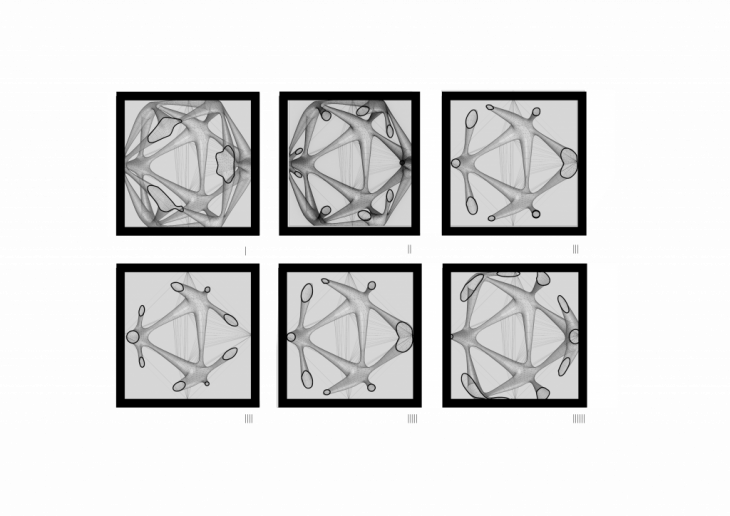

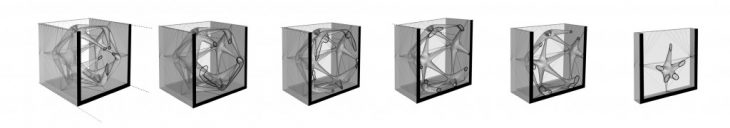

Morphological structure construction_longitudinal sequencencial sections

Morphological cross_Trasversal test