LAZER CUTTER

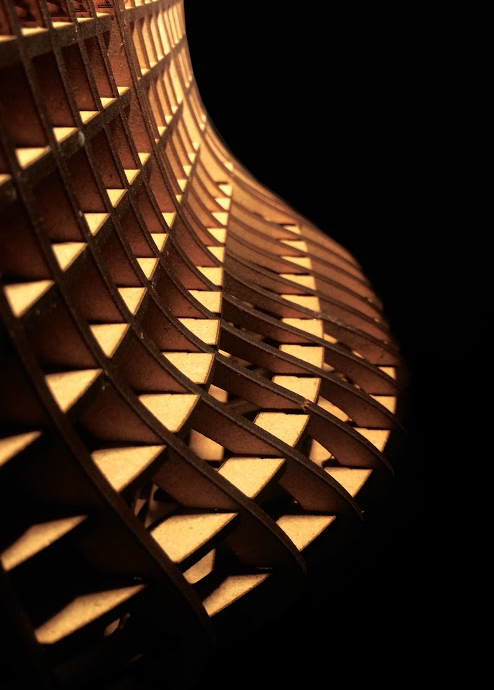

Object : Lamp

Students : Ilkim Er, Ça?lar Gökbulut

The aim here was to understand the advantages and disadvantages of Laser Cutting method, to learn about which materials are more suitable to use with laser.

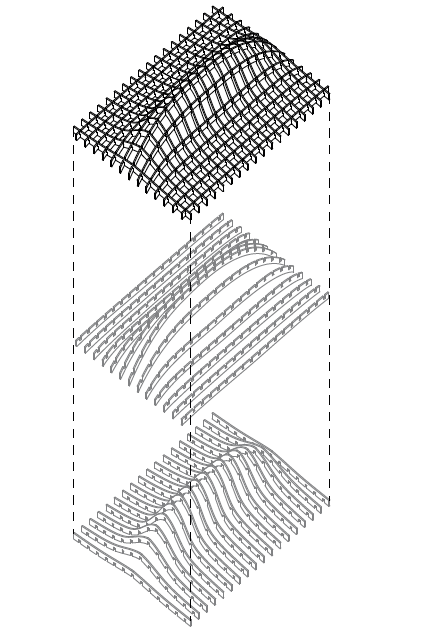

First we have created 3D model through Rhinoceros software and then we used a plugin for Grasshopper in order to split this 3D objects into pieces that can be cut by Laser Cutter, in order to create our lamp.

After cutting process we needed to bring pieces together and our lamp was ready.

pieces of our lamp

3D PRINTER

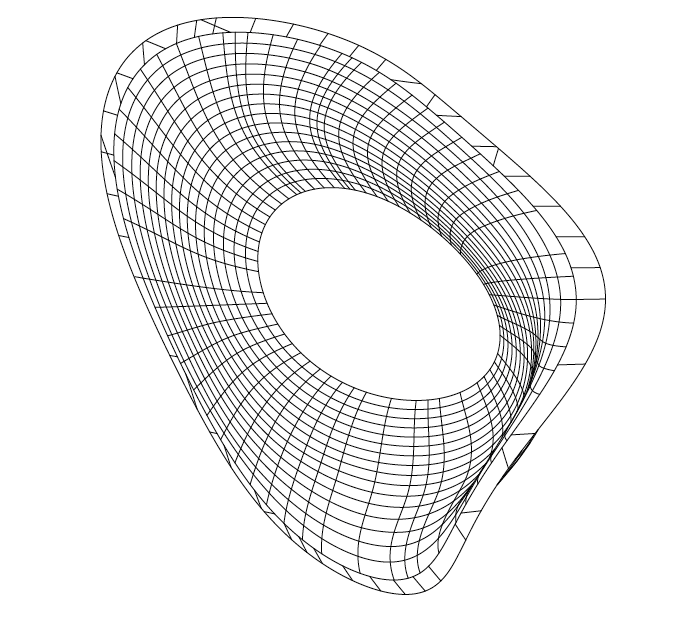

object : nuts bowl

students : Ilkim Er, Ça?lar Gökbulut

Another fabrication method we tried through the process was 3D printer, for this specific task we used Rhinoceros and Grasshopper softwares, after that we imported our model into Slic3r, to be able to 3d print.

MILLING

object : box for pens

students : Ilkim Er, Chiara Dal’Olio, Seda Tu?utlu

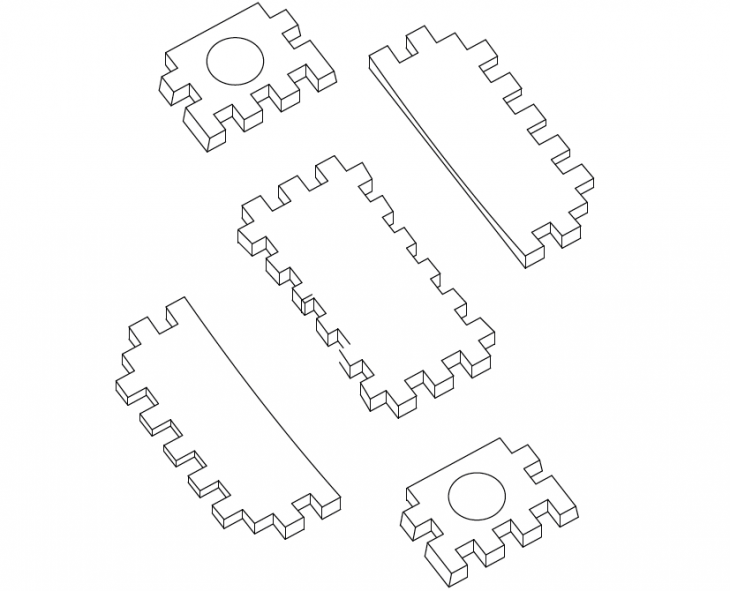

The last fabrication method we tried was milling, we again 3d modeled our objects, and used Rhinocam in order to export our model for milling machine.

Pieces of our 3D model, ready for milling machine

Our pieces ready to join

Milling Exercise at FabLab Barcelona

IaaC, Institute for Advanced Architecture of Catalonia

Master in City and Technology in 2016

Student:Ilk?m Er, Caglar Gokbulut, Chiara Dal’Olio, Seda Tu?utlu

Faculty: Djordje Stanojevic, Ricardo Valbuena