PARAMETRIC SKINS // Para Eco House In Laser Cutting

BRIEF

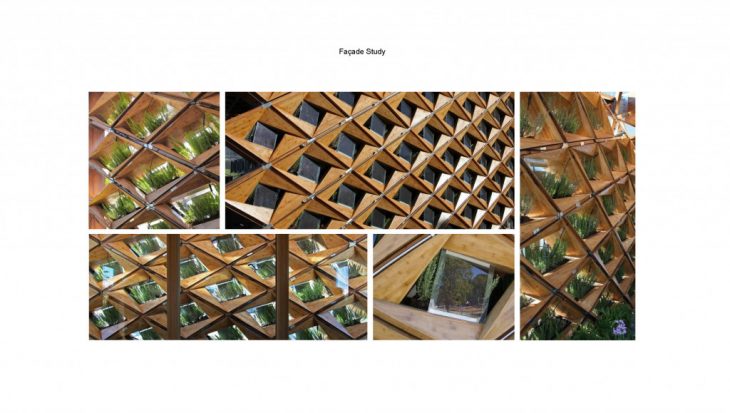

The project aimed to fabricate a prototype of the “Para eco-house” facade system and explore the capabilities of manufacturing processes through the laser cutting machine. The project made in one week of the Digital Fabrication seminar at IAAC, Barcelona, 2020.

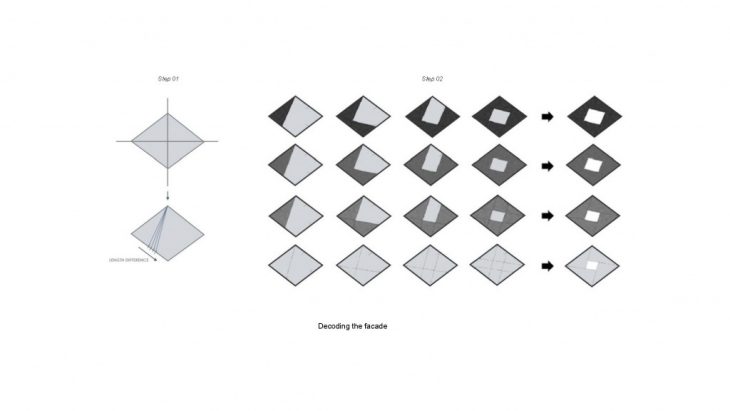

DECODE

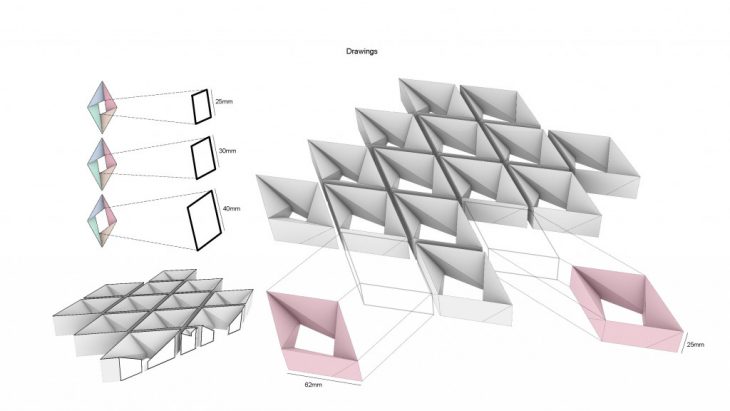

The four different sizes of openings are all located in the center of the cell grid. The size of the hole is adjusted by moving the position of each vertex.: select the same distance near the midpoint of each side of the diamond cell. The points are connected to their separated vertices in the same direction to form a diamond-shaped hole in the middle.

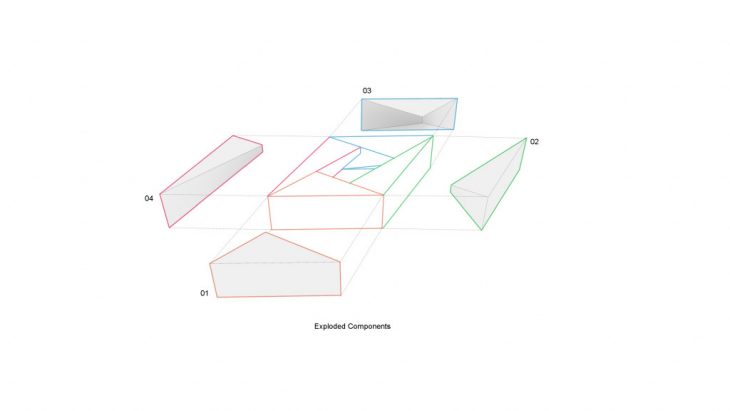

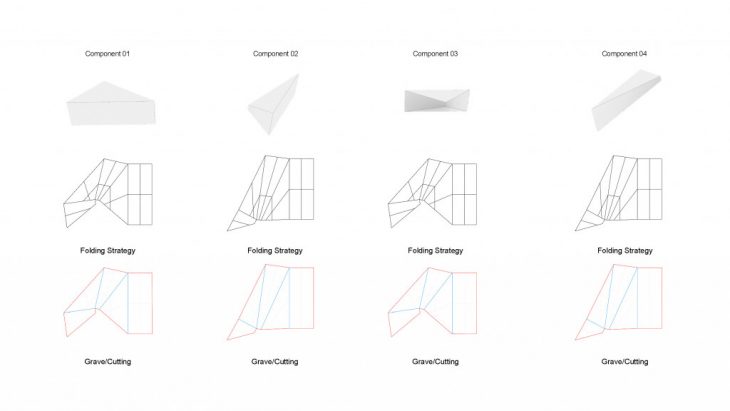

COMPONENT

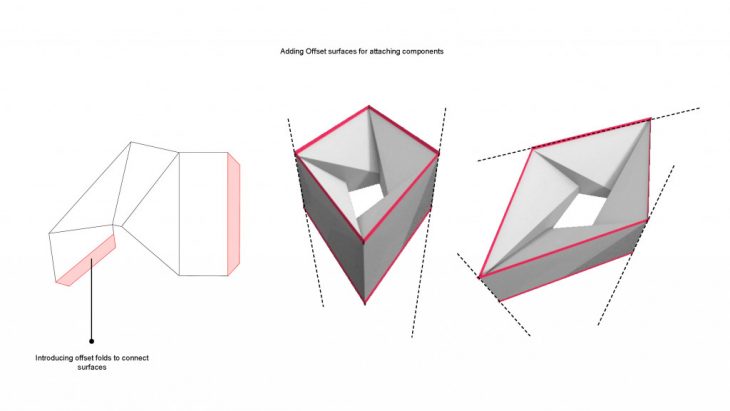

One unit can be separated into 4 parts, each component can be unrolled as one paper. To make it easy to fold, we have the engraving lines on paper and also adding the attachment on the edges.

MATERIAL

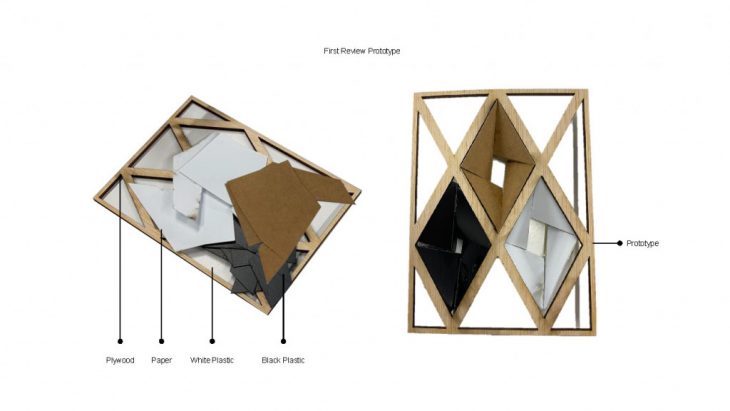

In the first prototype, we used 3 different materials for testing, and we choose paper as the cutting material because of its texture similar to the original bamboo and also it is good for folding,

STATISTICS

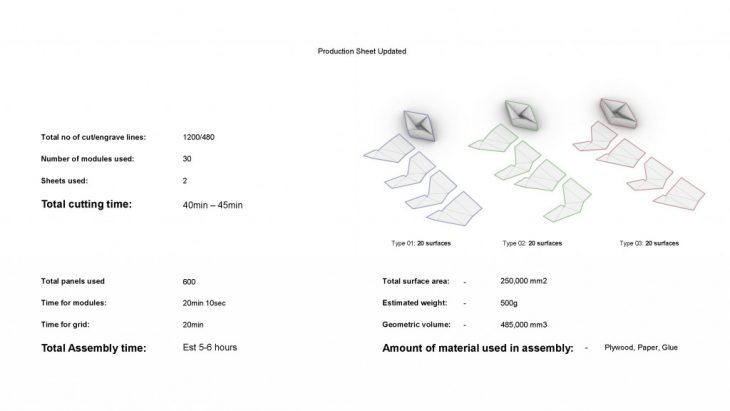

plywood grid cutting time:20 mins | paper modules cutting time:40 mins

PROCESS

Parametric Skins // Para eco-house is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master of Advanced Architecture 2020/21 by Students: Ziying Zeng, Victoria Fedorova, Amandeep Singh Sasan, and Faculty: Ricardo Mayor Luque, Lana Awad, Shyam Zonca