// INTRODUCTION

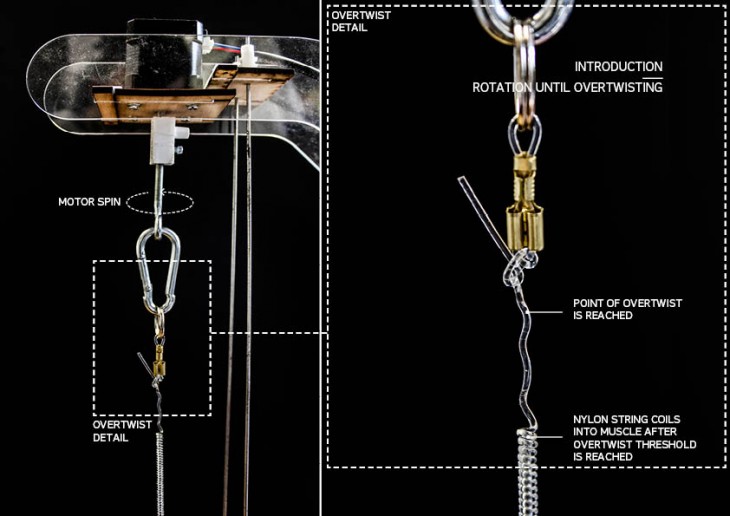

First published in 2014, nylon muscles are a relatively new smart material. Nylon muscles are created from commercially-available nylon fishing line. The process to convert the straight fishing line into a coiled muscle is simple. By keeping one end of the string in tension while twisting the other end (by means of a motor or drill), the string eventually over-twists and coiled unto itself. As a result, a nylon muscle is created.

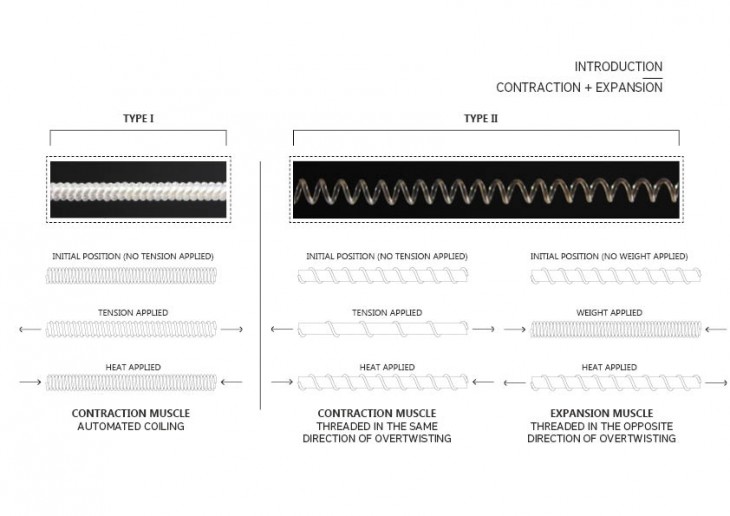

Nylon muscles are heat responsive and have shape-memory properties. Specifically, they can either contract or expand when heated, and return to their original length when heat is removed. Our project envisions the use of these nylon muscles to create a heat responsive, weaved volume. Our experiments and research thus far is outlined below.

The following videos showcase the expansion and contraction potential of Type II nylon muscles. In both cases, a heat gun was used to initiate actuation.

The following videos showcase the expansion and contraction potential of Type II nylon muscles. In both cases, a heat gun was used to initiate actuation.

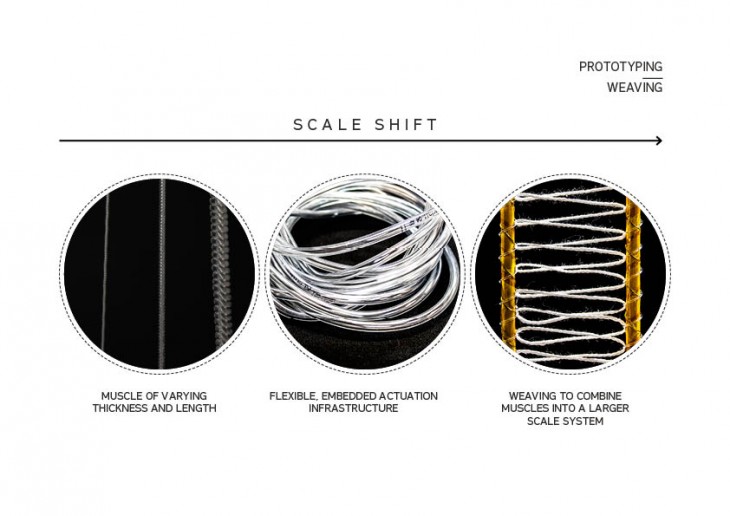

A significant amount of time was dedicated to exploring different fabrication processes and recording performance results. At an architectural scale, we envision a family of nylon muscles with different performance capabilities combined into one cohesive volume. As a result, we needed to control the actuation and response of each type of muscle before moving towards an application.

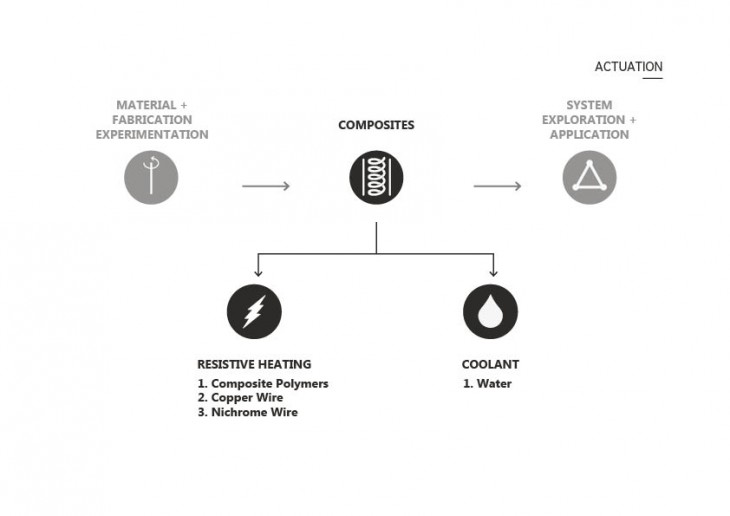

// ACTUATION

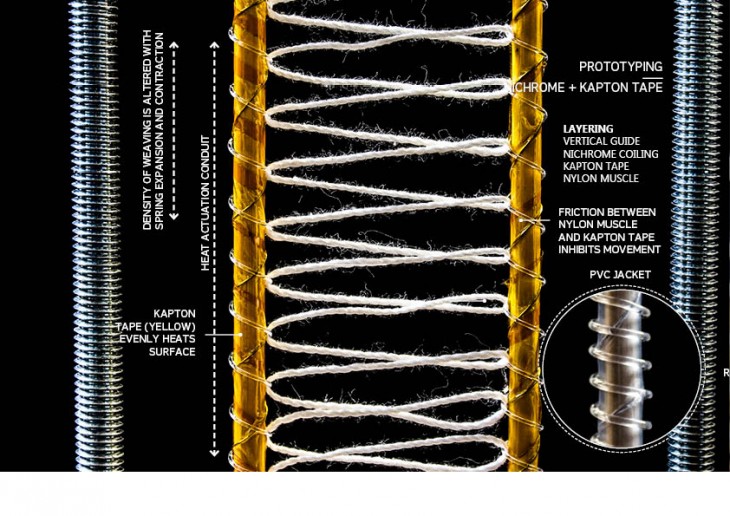

Nylon muscles are heat actuated, meaning they require heat source to respond. Depending on the fabrication process, the response can be either contraction or expansion. Our team explored multiple heat mediums, focusing mainly on resistively heating nichrome wire and pumping hot water.  Overheating and ultimately melting the nylon muscle commonly occurred. As shown in the below video, once the temperature threshold is reached, the expansion of the spring becomes unpredictable and eventually melts.

Overheating and ultimately melting the nylon muscle commonly occurred. As shown in the below video, once the temperature threshold is reached, the expansion of the spring becomes unpredictable and eventually melts.

Two types of controlled heating methods were used. The first, shown in the below video, showcases resistively (or electrically) heating nichrome wire.

Hot water was also used to actuate the nylon muscle. Water was pumped through transparent tubing, which the nylon muscle was coiled around.

// PROTOTYPING

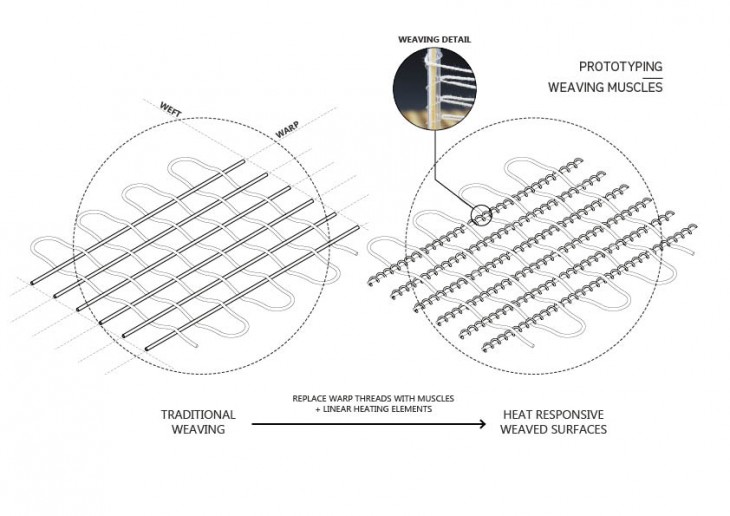

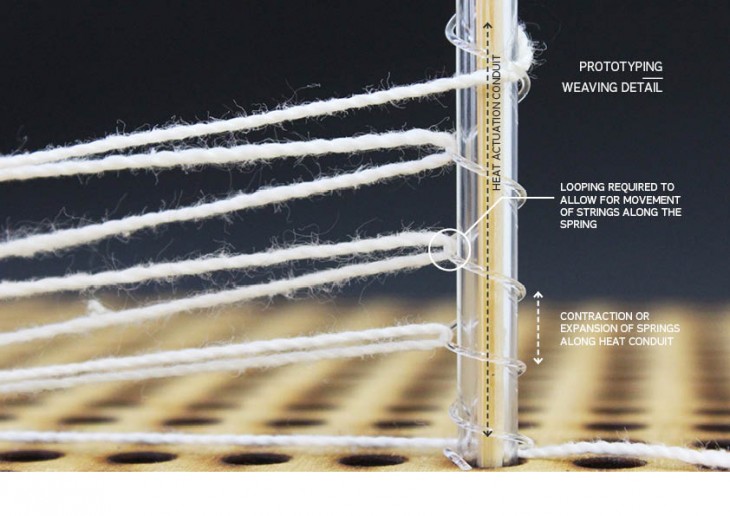

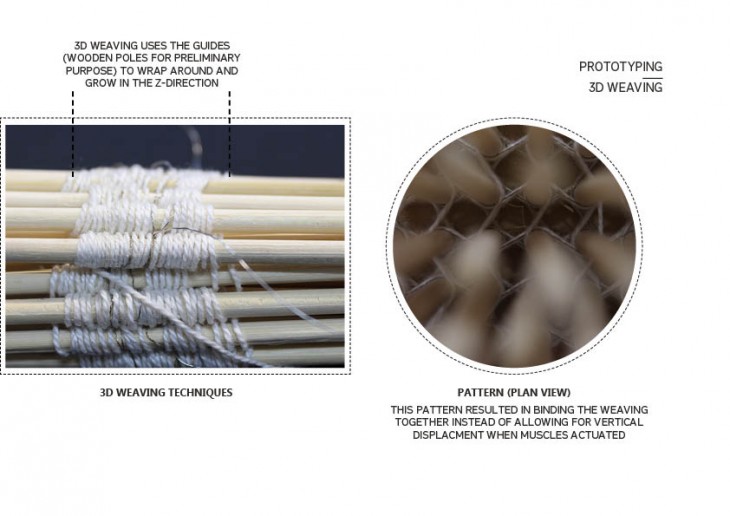

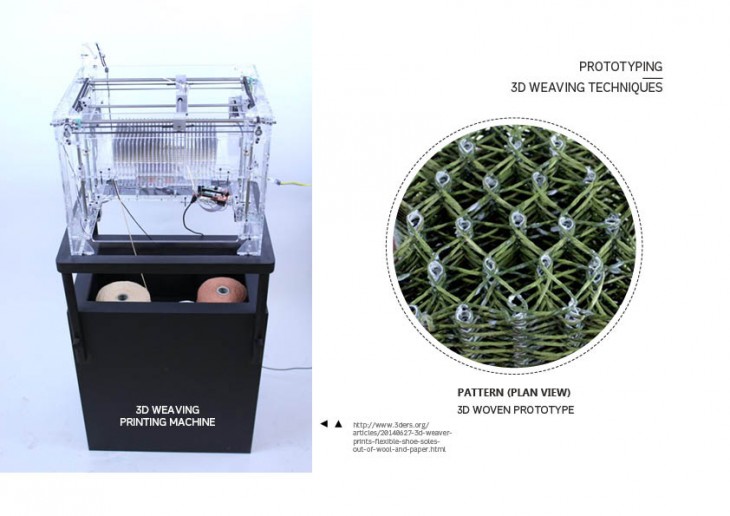

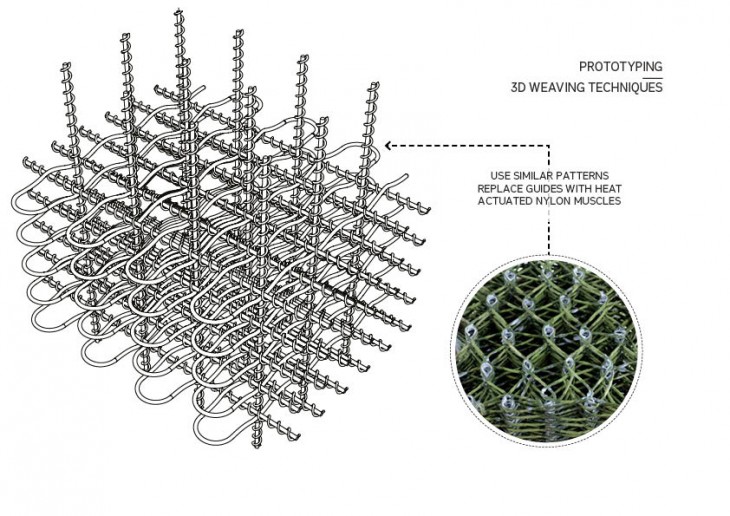

Prototyping was, and still is, an important step in our experimentation. Specifically, we wanted to explore different ways to combine heating infrastructure and the nylon muscle together into a volume or surface. We decided to experiment with weaving as our primary fabrication process.

To create weaved volumes, we researched 3-dimensional weaving precedents.

To create weaved volumes, we researched 3-dimensional weaving precedents.

// SYSTEM EXPLORATIONS + POTENTIAL APPLICATIONS

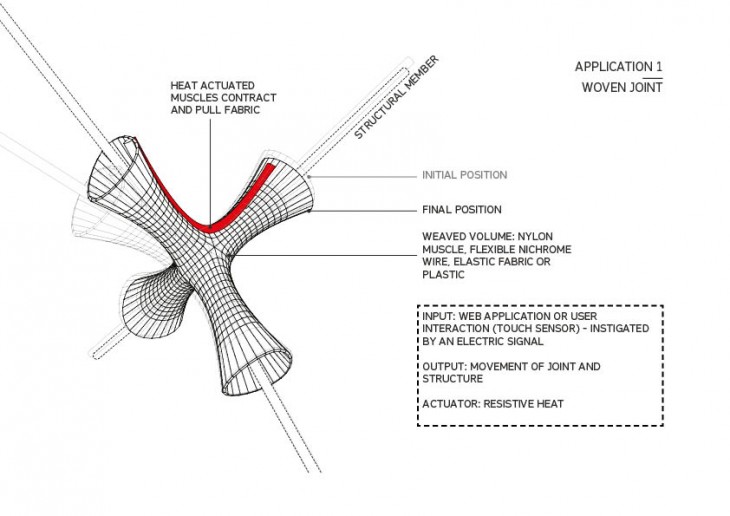

Moving beyond prototyping, we explored two potential applications for a woven, responsive architecture. The first design was a flexible, woven joint.

The following two simulations show the potential controlled movement which could be embedded into the joint. The second simulation is similar to the first, however, showcases the parametric nature of the joint.

The following two simulations show the potential controlled movement which could be embedded into the joint. The second simulation is similar to the first, however, showcases the parametric nature of the joint.

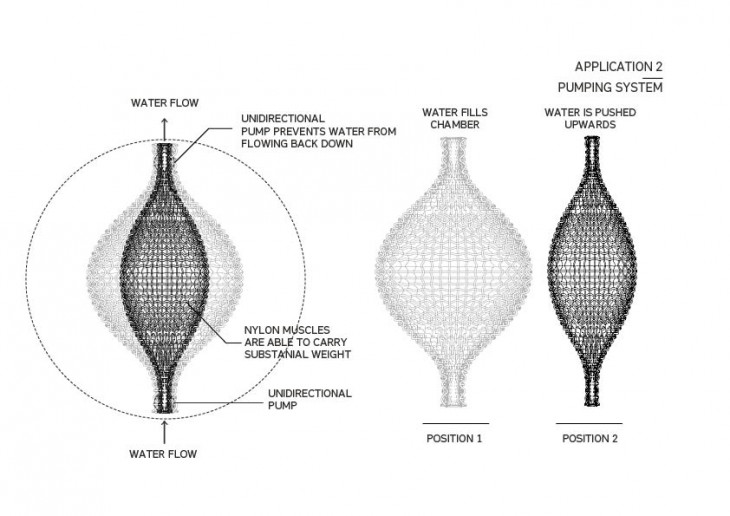

The second application explored was a pumping system. Nylon muscles would contract and expand, push water vertically upwards. We imagine a vertical irrigation system, distributing water to patio vegetation, green walls and green roofs.

Heat Actuated Nylon Muscles is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2016 by:

Students: Utsav Mathur, Jean Sebastian Munera and Connor Stevens

Faculty: Areti Markopoulou, Alexandre Dubor and Angellos Chronis