Fabricating a minimal gyroid is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Computation for Architecture & Design in 2020/21 by:

Keshava Narayan and Nawapan Suntorachai

Lead faculty: David Andres Leon Faculty Assistant: Dai Kandil

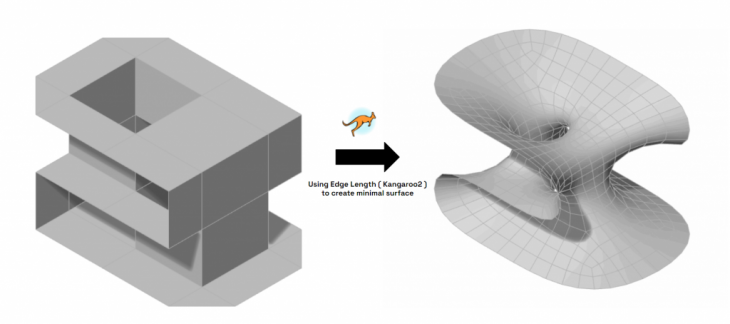

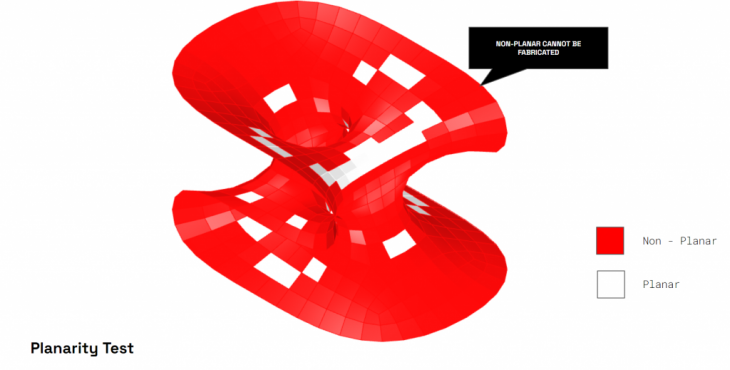

The major issue was that the mesh was a non-planar quad and hence hit had to be tested for planarity as shown below. Only 18 mesh faces were planar

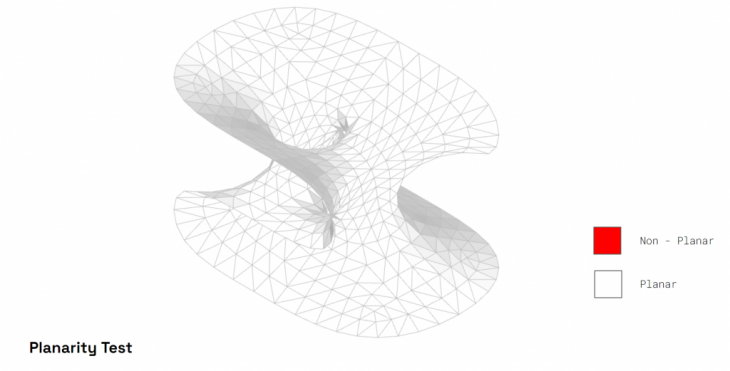

On converting the mesh into a triangular mesh, the mesh could be fabricatable as shown in the image.

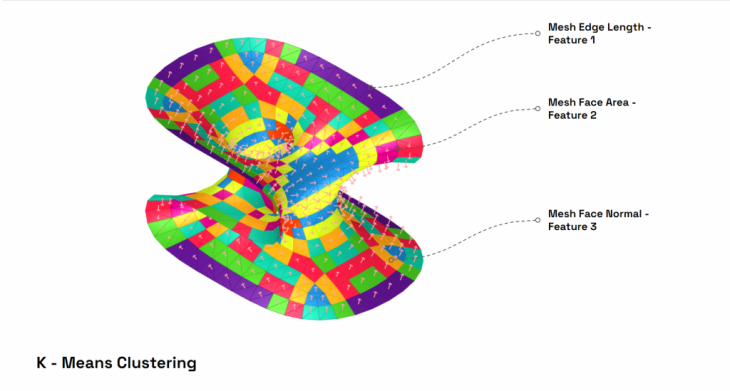

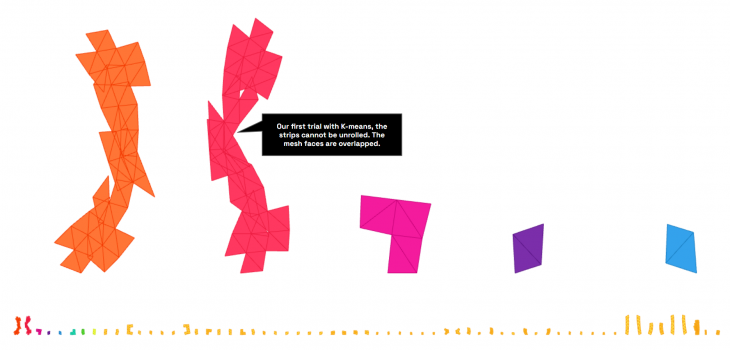

Method 1 – K Means Clustering

The first method tested was the k means clustering using SCci-Kit learn. The features measured were the mesh edge length, the mesh face area and the mesh face normals. The meshfaces were classified into 6 clusters based on these features.

However on unrolling the mesh, there were many overlapping faces which made the fabrication process difficult. Hence, another method needed to be explored.

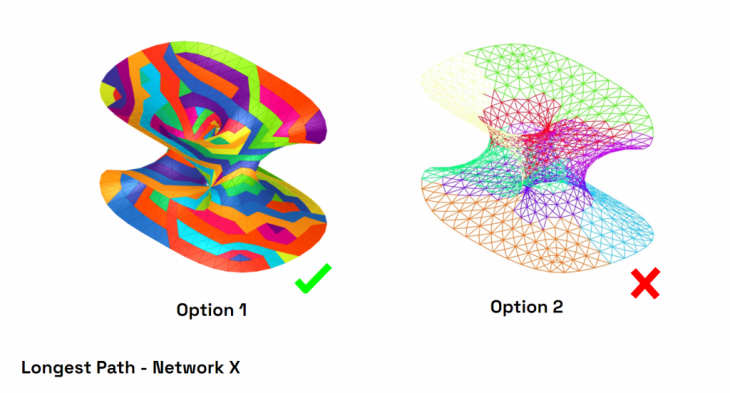

Method 2 – Longest Path

The second method chosen to be tested on the mesh is the longest path algorithm by NetworkX. As you can see in the image below this algorithm produces satisfactory mesh segmentation ready for fabrication.

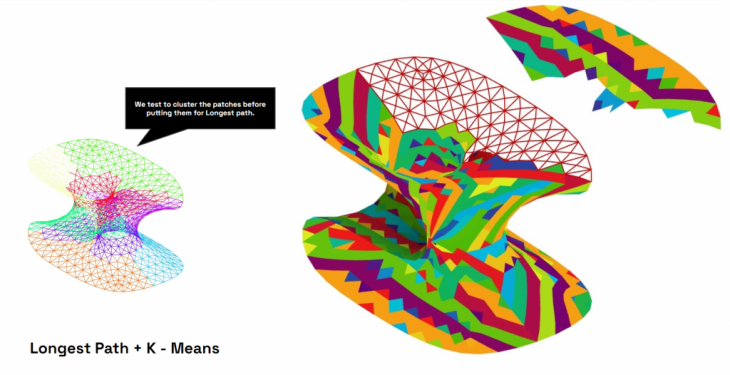

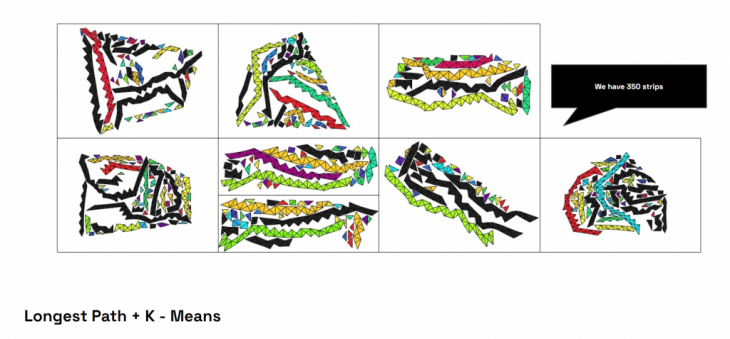

Method 3 – Integrating Longest Path with K-Means Clustering

The third method chosen to be tested on the mesh is to integrate the k-means clustering with the longest path algorithm by NetworkX. The larger patches are generated by using the k-means clustering and the strips are developed on these patches by using the longest path algorithm.

However, this did not perform as well as it was predicted and formed many islands and resulted in more number of strips.

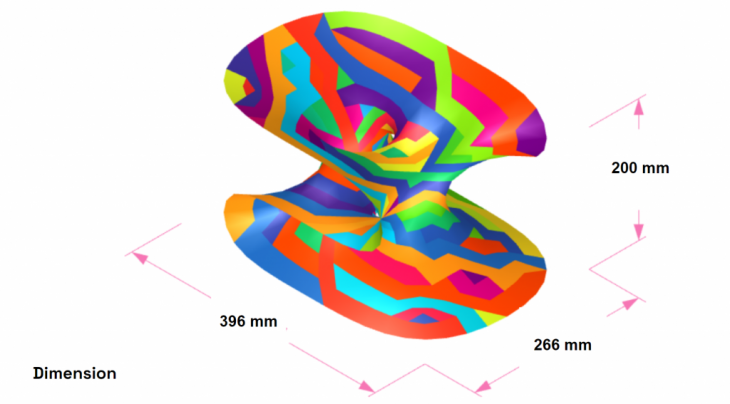

Dimensioning and Assembly.

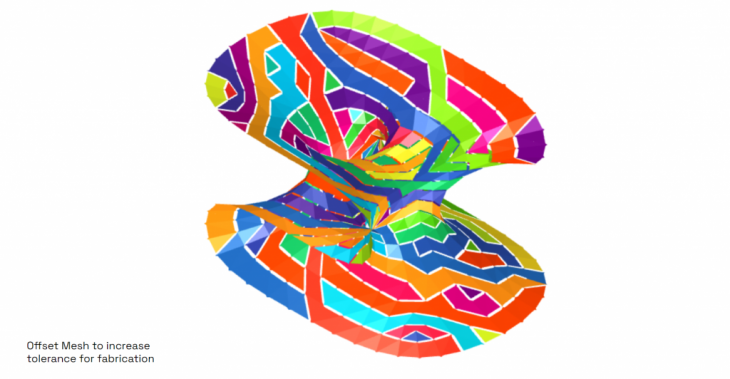

The dimensions of the final mesh chosen are as shown below. The mesh strips were offset from the base mesh to achieve tolerance in fabrication.

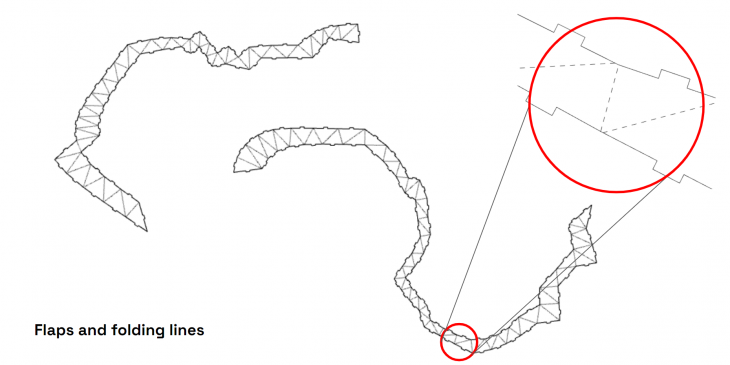

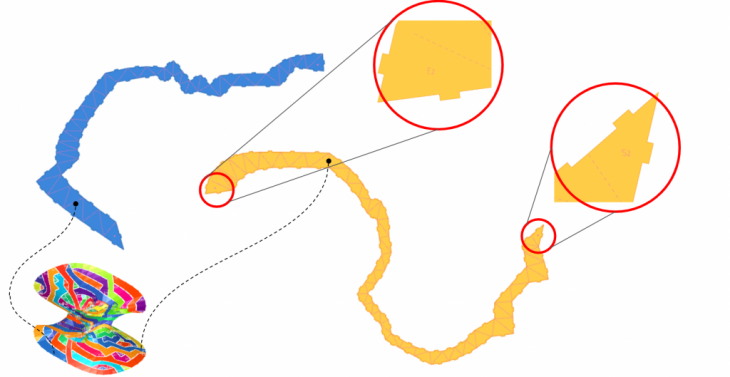

The strips were named from start to end so that the mesh can be easily assembled. Flaps and folding lines were generated in grasshopper.

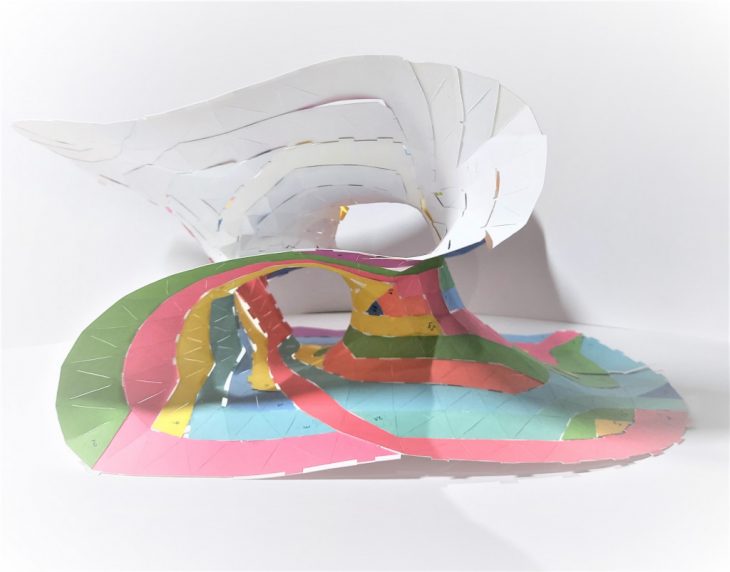

The Final Assembled Mesh

The assembled mesh and the video of assembly are as shown below.

</p>