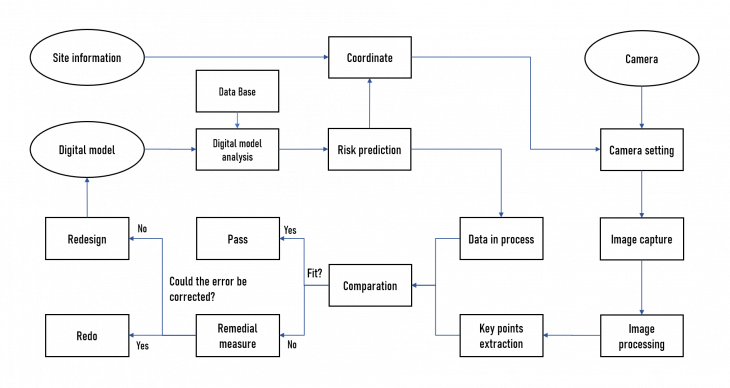

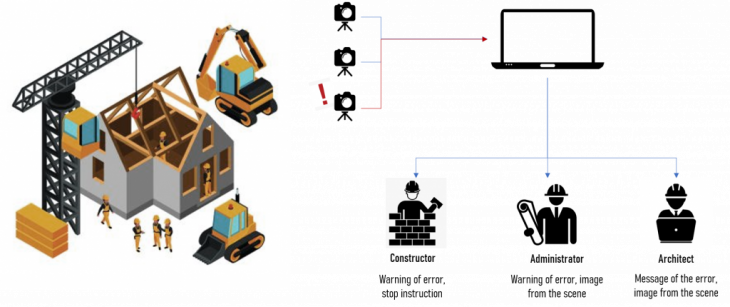

Eyes on construction is an attempt of using computer vision to supervise the construction process and prevent the mistakes happen. With the help of cameras that capturing the image of site and comparing the status with 3D model and identify if there is a mistake, constructors and architects can realize the mistake at first and correct them.

Issue

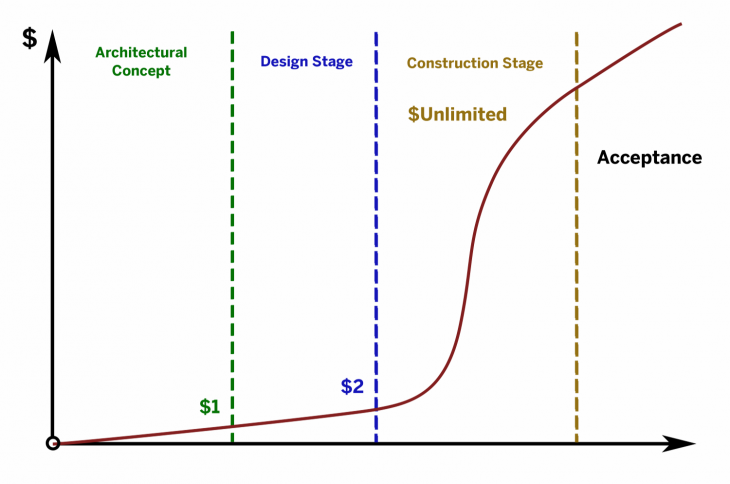

With the building function become more and more complex, construction and engineering practitioners have found it increasingly difficult to learn from their mistakes. Construction failure caused by those mistakes usually lead to huge economic loss.

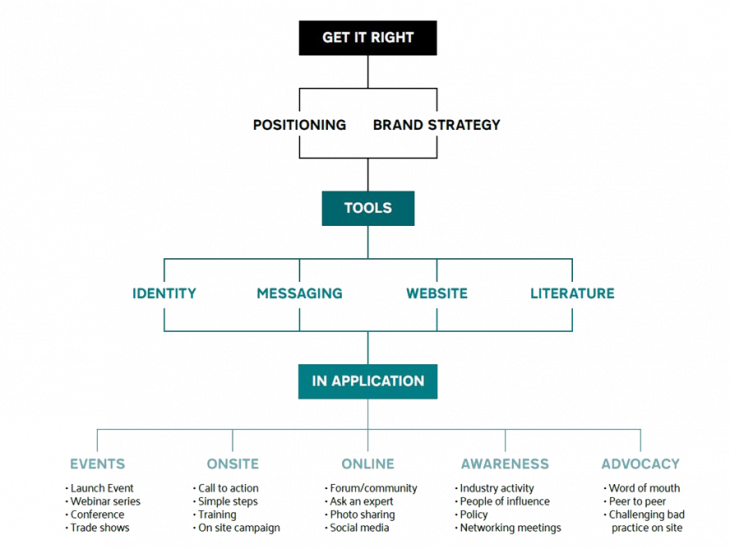

According to a report from the U.K. organization GIRI (get it right initiative). Only in the U.K., construction error cost 5bn pounds economic loss per year. 21% of total construction cost is for errors which contains latent defects (3%), indirect costs (7%), direct costs (5%), Unrecovered process waste (6%). Around the world, there are many regions has more construction than the U.K., the global economic loss coursed by construction error is incalculable.

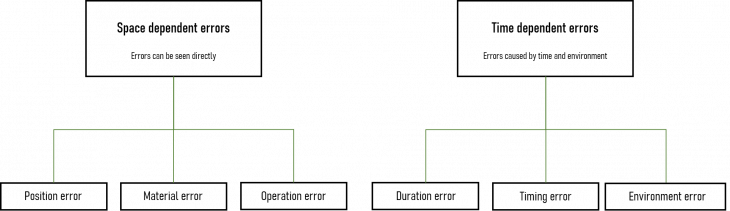

Research about construction errors

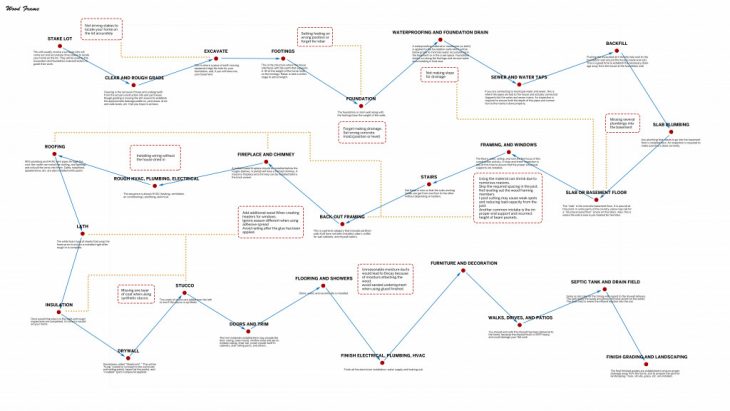

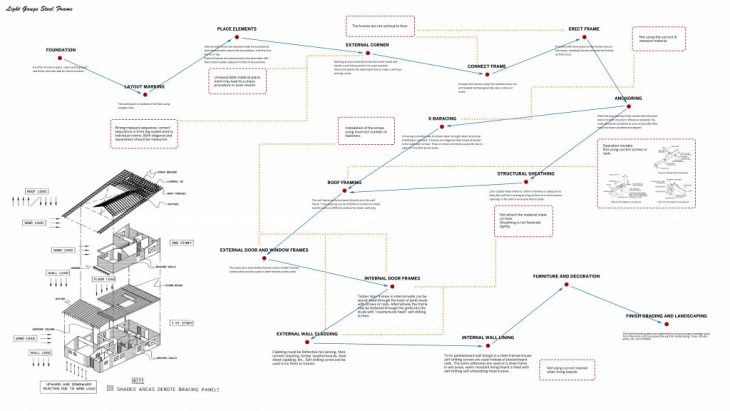

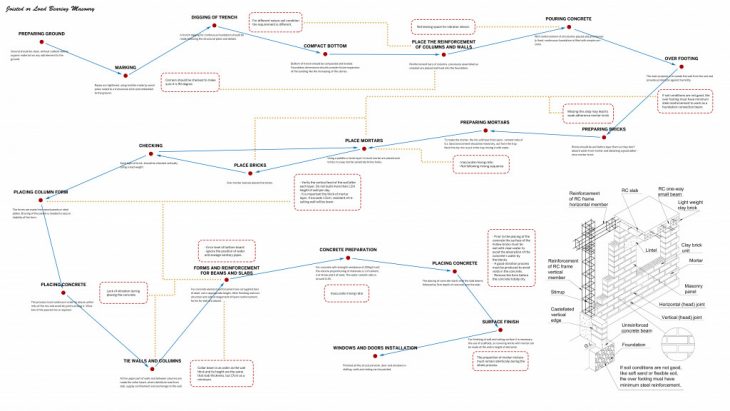

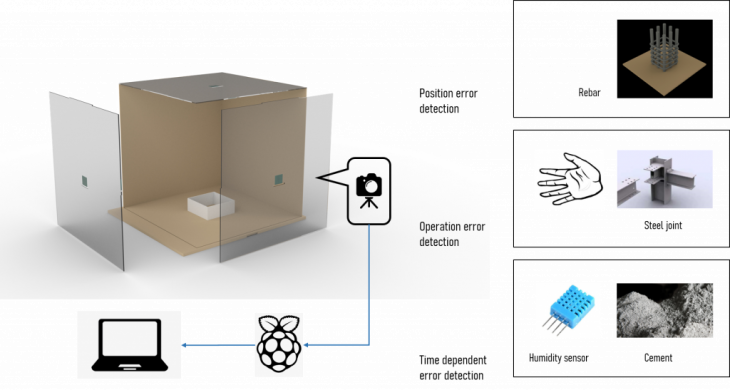

Even though construction is a complex process with huge operating steps, all these errors can be classified into two categories, space dependent error and time dependent error. Space dependent error people can see directly, like placing rebar on an incorrect position when doing reinforcement, combine steel beam and column in an inadequate way, or using wrong dimension screws when fasten elements. Time dependent errors are usually not caused by constructors’ activities themselves, but the time they do. For example, when making concrete, remove formwork before the concrete dry, the time is changing depend on environment; when doing structural sheathing, if material sheet cannot be attached on time, the protection will not work; when mixing concrete, there should be enough stir time.

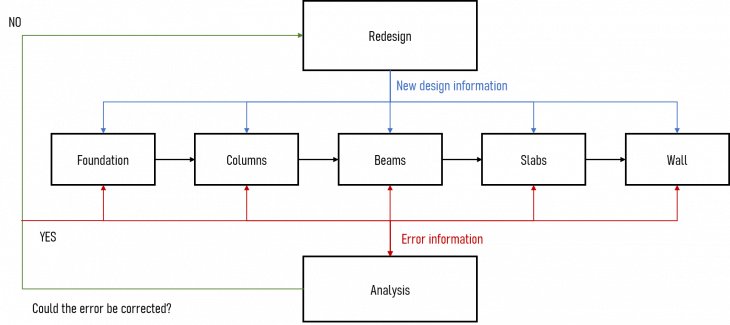

Constructions errors are seldom existing individually, especially those appear in early stage. If a mark made in measurement stage is incorrect, the foundation would have a wrong size, then the column might be placed on a wrong position. Which means the beam and slab size are cannot match columns. The whole construction should be redo. A small error may lead to a terrible result, that is chain reaction. A huge amount of wealth and material could be wasted. Even just not accurate enough at beginning, the error could accumulate step by step and finally show a big mistake. That is why making the work as accurate as possible from the beginning is extremely enough during construction process.

State of Art

Traditional method focuses on management. Conscientious construction company could provide adequate training to their employees. A reasonable schedule can help constructors working systematically and reduce error happen. Management methods like responsibility and supervisor can help constructors concentrate on their work and discover error as early as possible. Positive action can reduce error occur. But it still relies on human’s willing to control the error.

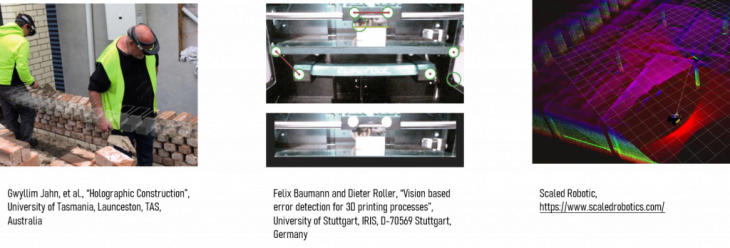

The three references are base on emerging technology. They give a good inspiration of how to apply new technology on this field. They all require heavy and complex devices. So, the goal of my research is provide a reliable technical solution without heavy and complex devices. More flexible and easier to use.

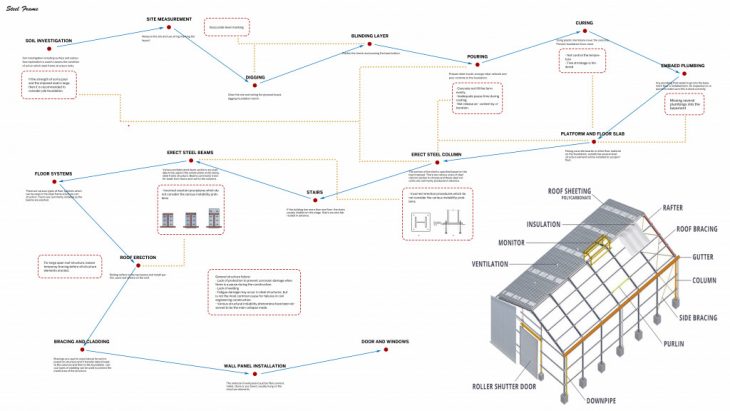

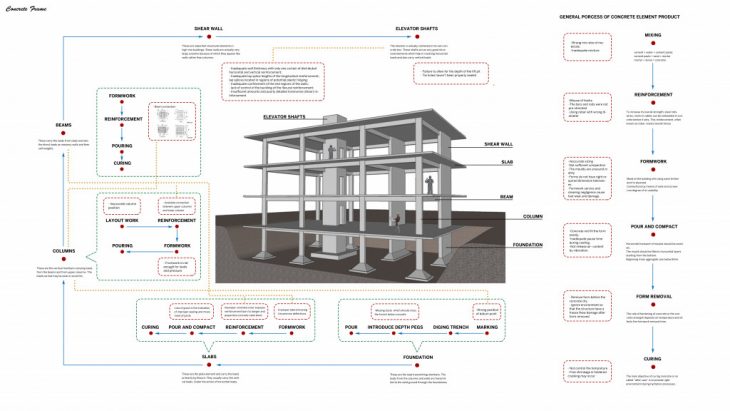

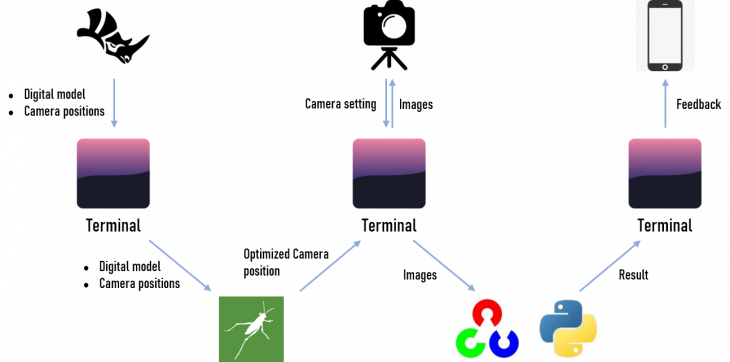

Workflow

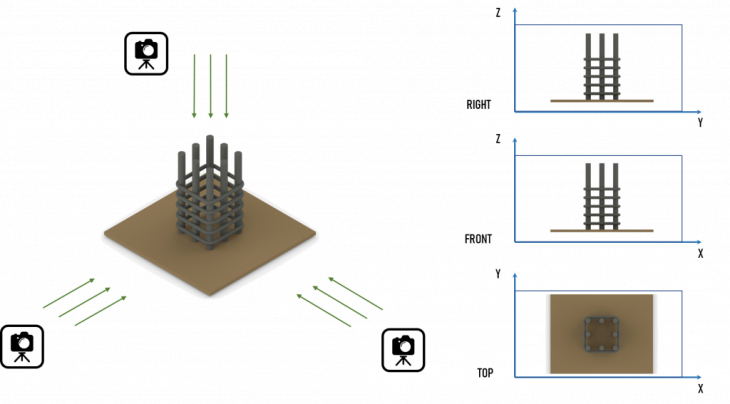

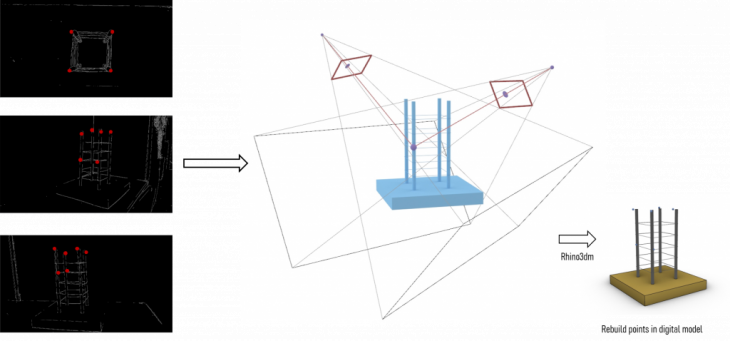

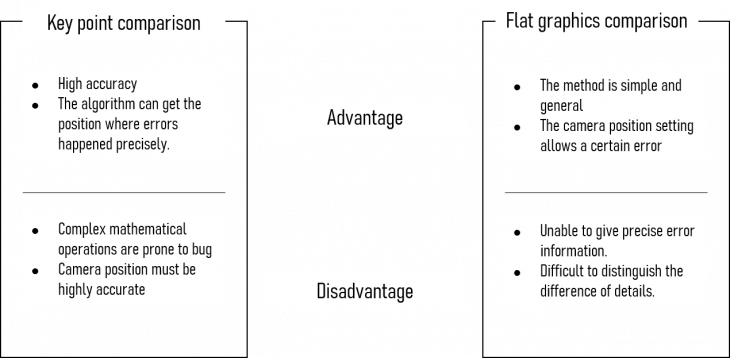

3D detection

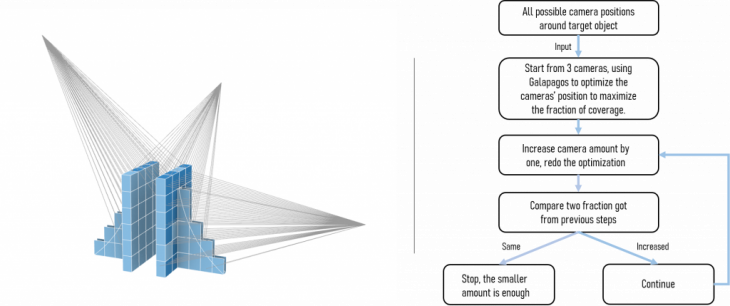

To get the full information of target, multiple cameras will be used.

camera setting

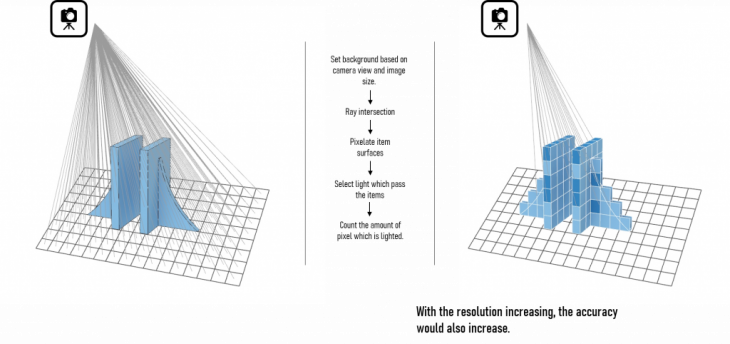

Simulate camera capturing in grasshopper

Optimize camera amount and position.

Image processing

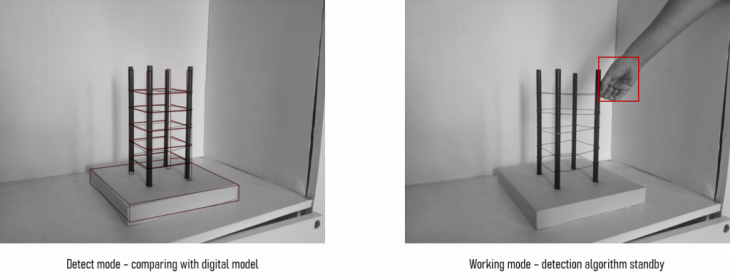

The detection will stop while constructor working and check once the work finished. So hand detection can be used as a switch for detection algorithm.

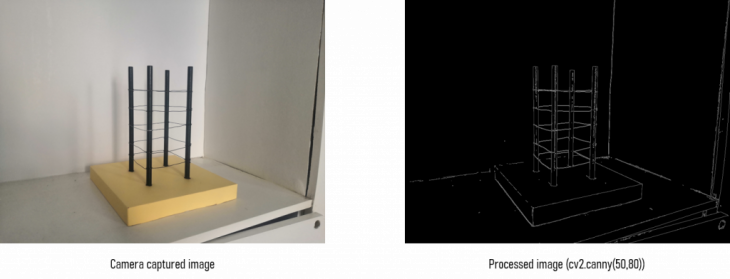

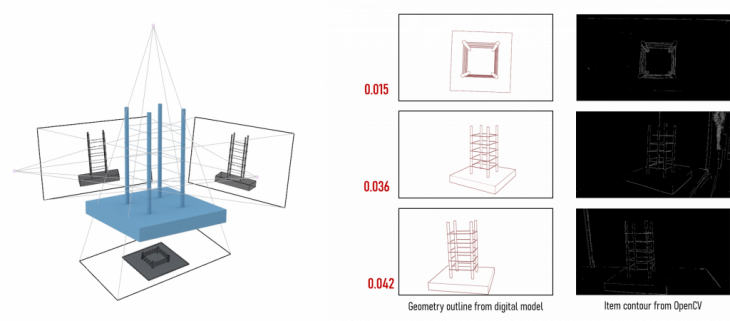

Using OpenCV. canny to draw the edge of the image

Check the distance between points and the positions they supposed to be. If the value is within the set range, it is correct, otherwise there might be an error.

Use OpenCV.orb to detect the similarity of the specified range

feedback

HARDWARE

Hardware is not the core of this project, any open source device with camera which can send the images to the camera is possible, Raspberry Pi, GoPro are all good devices.

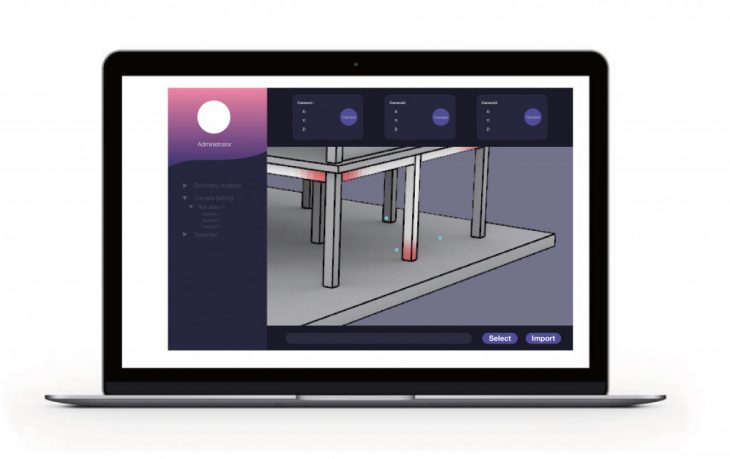

UI design

Data flow of the whole system

Interface – Digital model and camera position setting

Interface – Camera amount and position optimization

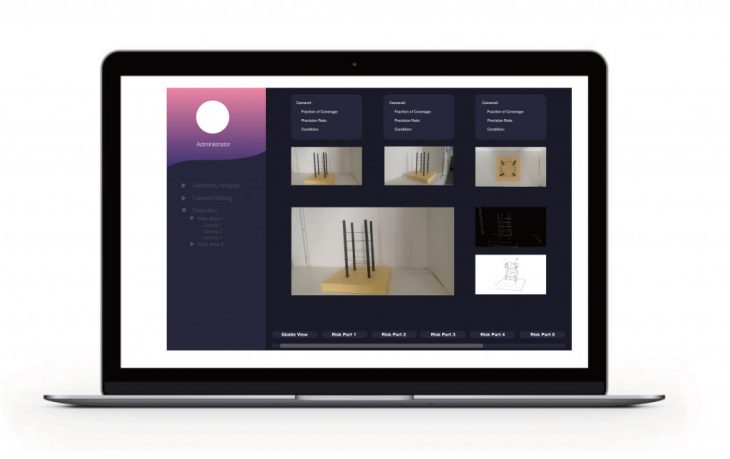

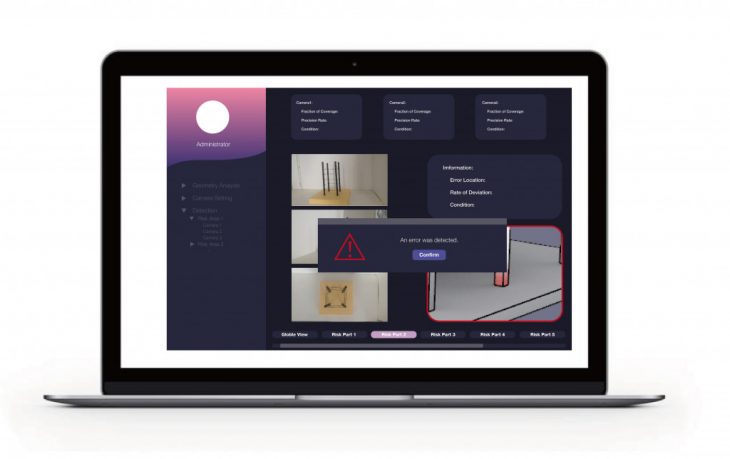

Interface – Detection

Interface – Error discovered

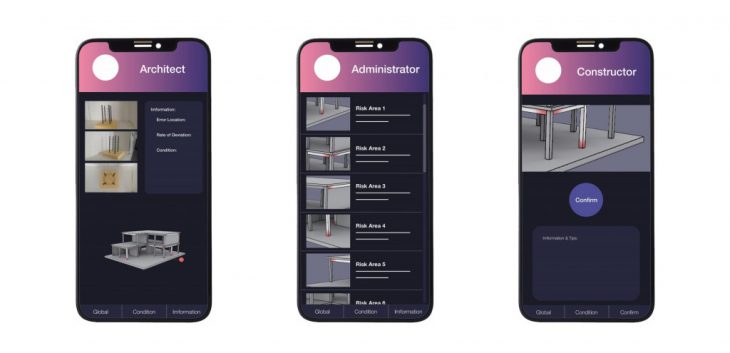

Interface – Cellphone feedback

experiment

Monitoring demo

application

conclusion

According to experiment and coding test, the whole process is feasible. The algorithm of comparison still need optimization to increase accuracy, due to lack of experiment on real site, the feasibility on a real site is still in doubt. More research and experiment is need in the future.

Future Efforts

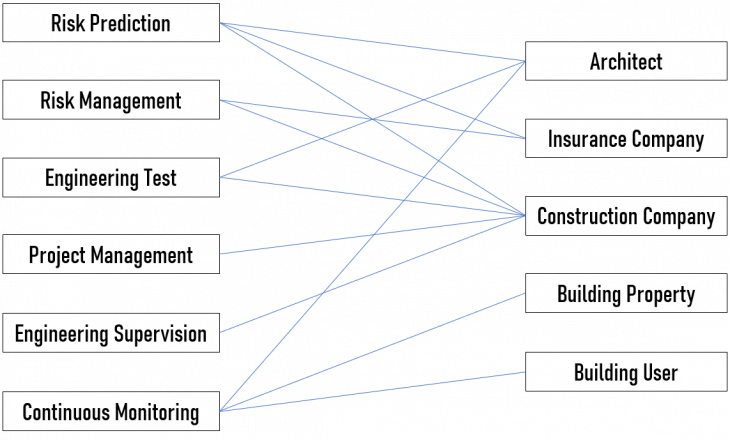

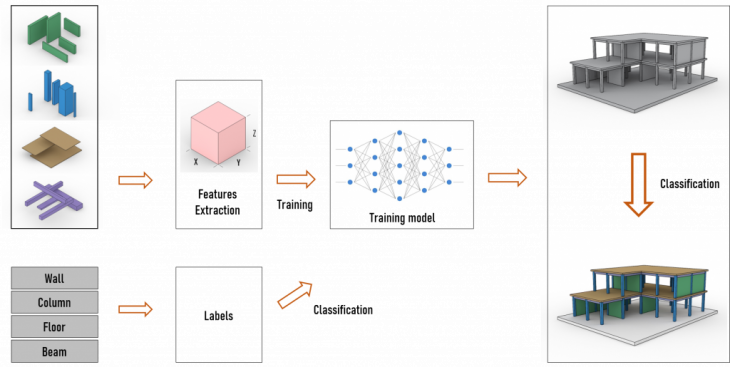

digital model analysis is based on machine learning, using the objects’ X, Y, Z dimension as features to ditinguish wall, beam, floor and column, after trainning, the algorithm can classify the elements automaticly. And this classification can help on risk prediction.

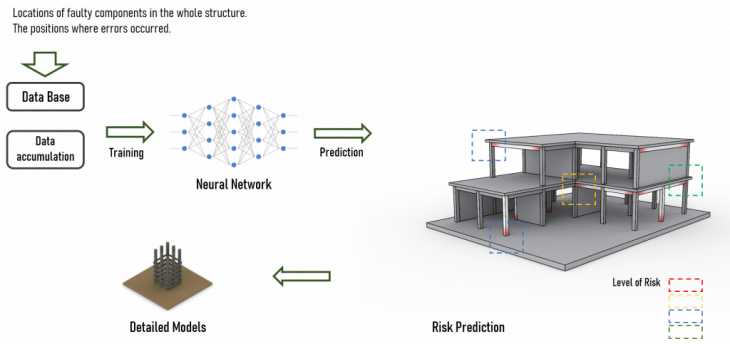

Collect the data of the position construction errors happened as a data base. using the data base to train a model to predict where are risk parts in a building model. With the data accumulate during the system working, the data base could be richer and the prediction could be more accurate.

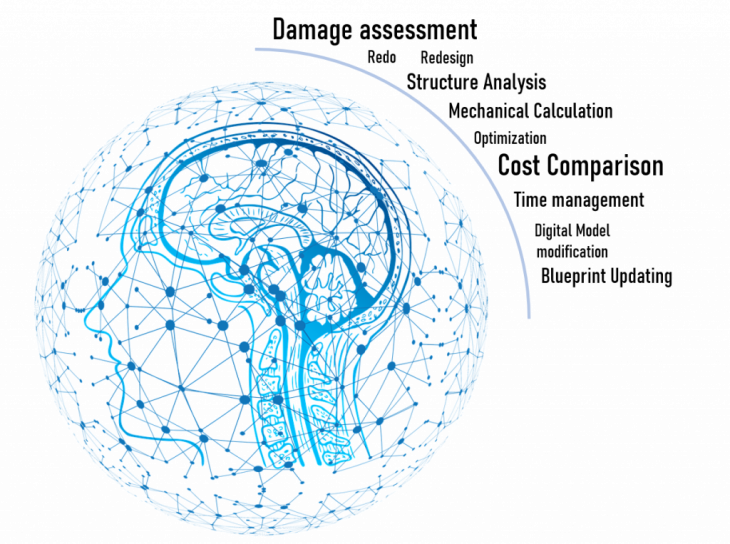

Sometimes, the construction errors detected cannot be simply corrected. A wise solution is changing design adapt to the error. This process refer to damage assessment, structure analysis, and a lot of Mathematical calculation. AI has a huge potential to help doing this job, but this require huge data and complex algorithm which is hard to finish at present. So, the remedial mearsure has a huge potential to explore in the future.

Eyes on Construction is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master of Advanced Architecture 2019/20 by Students: Hongyu Wang and Faculty: David Andres Leon