Engrave | Deform | Cut

Engrave | Deform | Cut is a proposal for a facade which uses sheet material and a 3 step machine process with the intent to explore ways of mass customization through robotic fabrication and computational design.

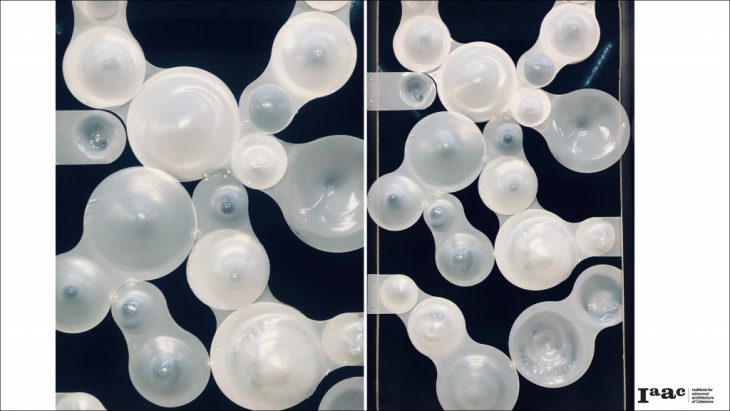

The final proposal uses PETG sheets and heat to achieve deformation.

Manual Bending

Material: Plakene

Thickness: 0.5mm

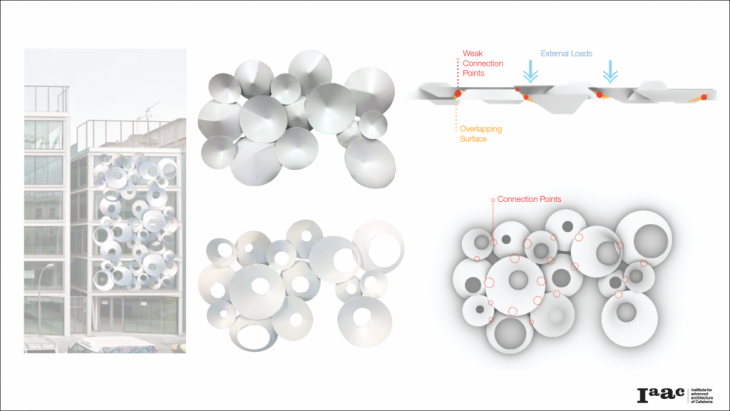

A series of experiments are conducted by manually bending plakene sheets and holding them together with glue. The resulting shapes are weak at their connection points. In terms of geometrical performance, the single piece on its own becomes stronger and stiffer after the deformation.

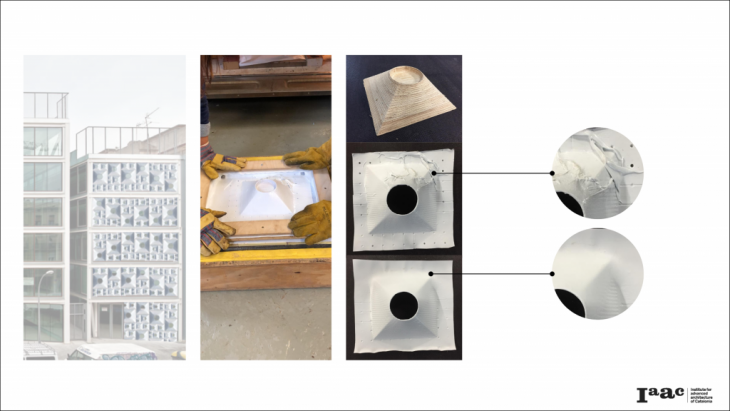

Thermoforming

Material: Plakene

Thickness: 0.5mm

A plakene sheet is heated to a forming temperature and forced onto a mold by vacuum. With this process, the sheet is formed to a permanent shape. Several molds would have to be produced in order to achieve a variety of shapes with the method thermoforming. At the same time, due to a sharp vertical angle, the material crumbles at the corners.

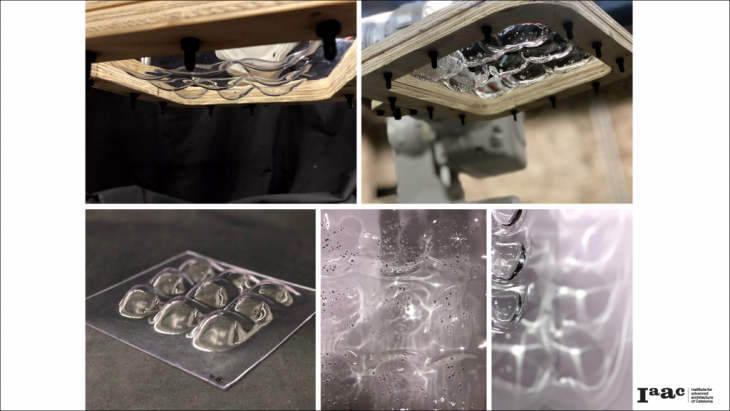

Heatforming with ABB-140

Test on Plakene

Material: Plakene

Thickness: 0.5mm

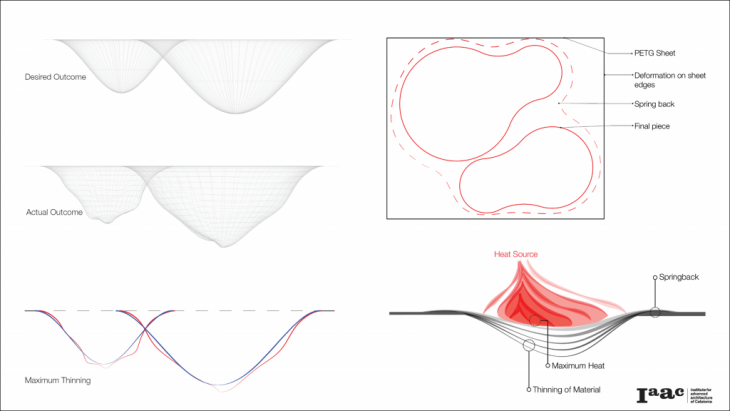

For this initial experiment with the robot, a heat-gun is mounted as the end tool on a ABB-140 and the plakene sheet is held on a frame on the table. This set-up is modeled into Rhino and the tool-paths are designed in grasshopper. The robot follows the given tool-paths while the heat-gun is turned on to create the deformation. During this, certain necessary parameters were identified, such as; the speed of the robot, the distance from the tool to the sheet and the temperature of the heat-gun to reach the maximum desired deformation of the material while avoiding puncture.

Test on PETG

Material: PETG

Thickness: 1.5mm

A 20x20cm frame is constructed as an end tool for the robot, the sheet is being held by the edges inside the frame, while the heat-gun is mounted on the table in a steady position.

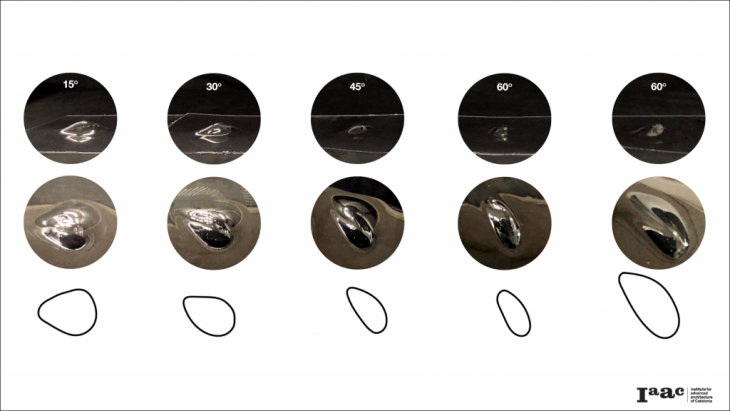

To understand the behavior of the material during this fabrication process, several parameters are being tested individually: Distance, angle and tool-paths.

Variable: Distance between the sheet and the heat-gun

Variable: Angle between the sheet and the heat-gun

Variable: Different Tool-path Designs

By changing one parameter at a time, it is possible to examine each outcome and understand the relationship between the digital and the physical.

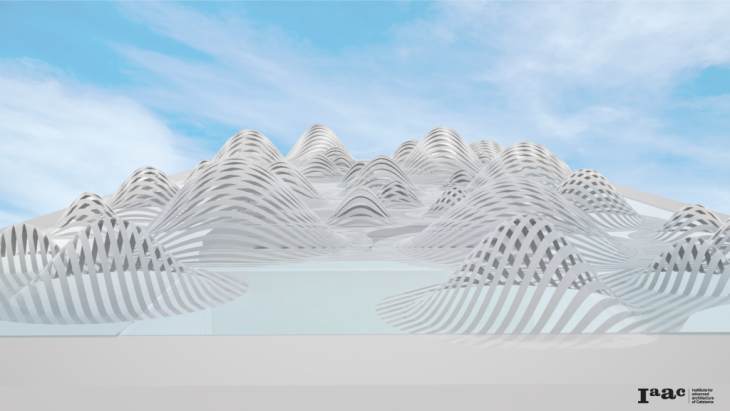

Facade Design

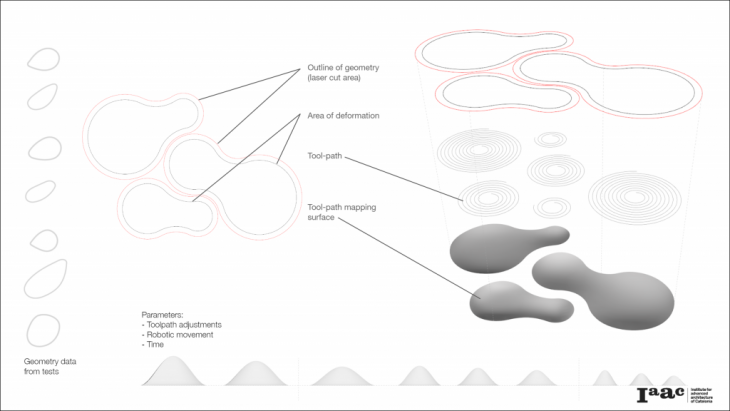

The results from all previous experiments indicate that the occurring deformation will create a round shape, this was taken into account in the development of the final design.

Spiral tool-paths were mapped on surfaces in grasshopper to generate the robotic simulation. Once the final definition is set, it is possible to go back and change individual parameters, such as distance or speed, to achieve a different deformation.

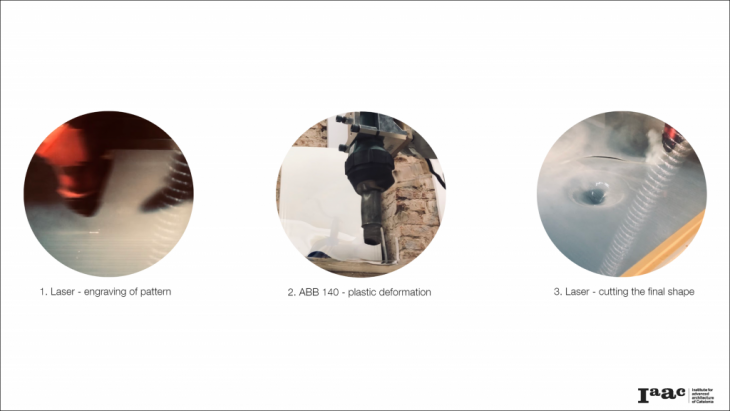

To reach the final geometry, a 3 step machine process is required.

Engrave:

PETG sheets come with two protective layers, one white and one clear. The white layer was kept on the material and engraved in stripes with a Trotec laser. As a result, when the maximum deformation occurs, the stripes will want to separate and make the depth of the deformation more visible.

Deform:

By using a heat-gun as an end tool for the ABB-140, the sheet deformation process takes place.

Cut:

Third and final step: the PETG sheet is placed on a frame and back in the Trotec laser, where it is being cut around the deformed area to get the final piece.

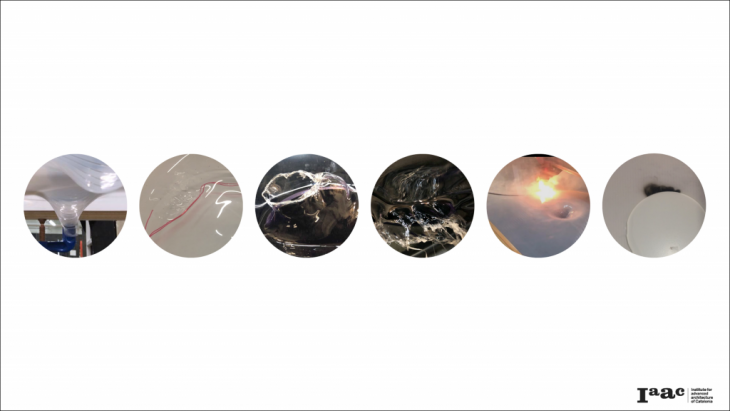

Issues encountered:

– Puncture of PETG sheet due to excessive heat or airflow in one area

– Fire during the last step due to springback of the material and loss of focus with the laser

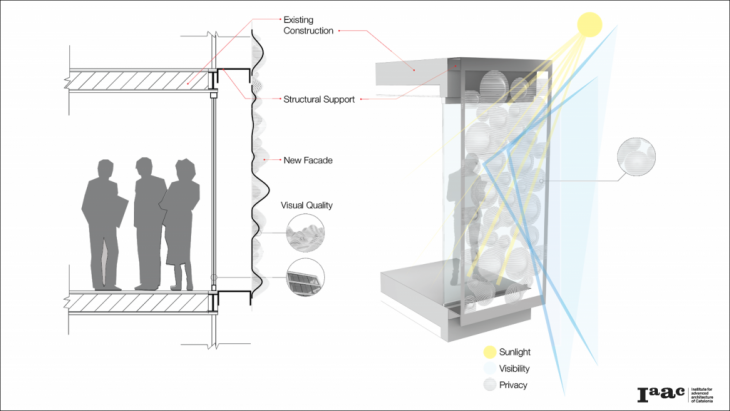

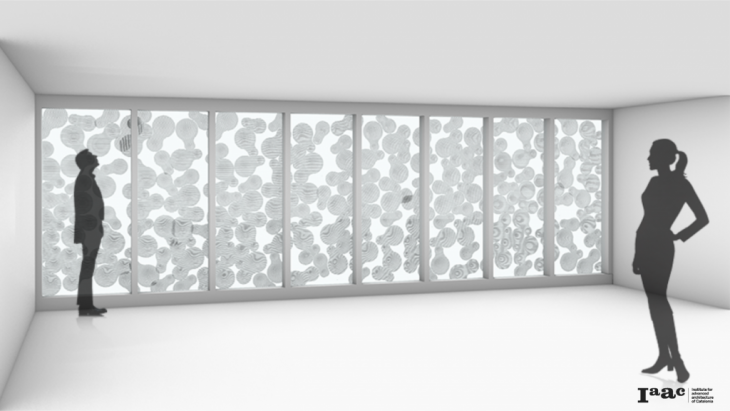

Architectural Application

Facade Performance

This facade aims to enhance shading and privacy while allowing natural light to enter the space and views of the street and the sky.

Future Vision

This process can be translated into glass. It allows further exploration of these fabrication techniques by using more powerful industrial machines and more controlled environments.

Engrave | Cut | Deform is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Masters of Robotics and Advanced Construction in 2019-2020 by:

Students: Gjeorgjia Lilo, Maria Isabel Cousseau, Muhammad Mansoor Awais

Faculty: Alex Dubor, Raimund Krenmueller