Created from sustainably sourced softwood, Accoya wood matches or exceeds the durability, stability and beauty of the very best tropical hardwoods.The Accoya wood production process takes sustainably-sourced, fast growing softwood and, in a non toxic process that ‘enables nature’, creates a new durable, stable and beautiful product – that has the very best environmental credentials. Dimensional stability Swelling and shrinkage reduced by 75% or more// Doors and windows open effortlessly year round//Paints and varnishes last 3 or 4 times longer, greatly reducing maintenance costs Class 1 durability The most durable wood possible// More durable than teak and the world’s other most durable woods//Perfect for outdoor use Long lasting Lasting at least 50 years above ground and 25 years in ground Rot& insect barrier Accoya wood is indigestible to insects and microorganisms and is therefore more resistant to decay// Barrier to wood-destroying fungi // Accoya wood is virtually rot-proof Perfect for Coating Easier to coat: less preparation and sanding between coatings required//Improved dimensional stability and UV resistance improves the life of coatings//Perfect for transparent, translucent and opaque coatings Naturally Insulating Accoya wood offers improved thermal insulation in comparison with commonly used wood species//Accoya wood is ideal for applications where energy conservation is important Non- Toxic Accoya wood is non-toxic, protecting the environment from the harmful effects of poisons leaching out of typical wood treatment//Accoya wood may be safely reused and recycled From sustainable sources Sustainably sourced, including from FSC, PEFC and other regionally certified woods//Naturally renewable 100% recyclable Fully reusable and recyclable // Reuse is recommended but Accoya wood may be safely incinerated for bio-energy or composted

Created from sustainably sourced softwood, Accoya wood matches or exceeds the durability, stability and beauty of the very best tropical hardwoods.The Accoya wood production process takes sustainably-sourced, fast growing softwood and, in a non toxic process that ‘enables nature’, creates a new durable, stable and beautiful product – that has the very best environmental credentials. Dimensional stability Swelling and shrinkage reduced by 75% or more// Doors and windows open effortlessly year round//Paints and varnishes last 3 or 4 times longer, greatly reducing maintenance costs Class 1 durability The most durable wood possible// More durable than teak and the world’s other most durable woods//Perfect for outdoor use Long lasting Lasting at least 50 years above ground and 25 years in ground Rot& insect barrier Accoya wood is indigestible to insects and microorganisms and is therefore more resistant to decay// Barrier to wood-destroying fungi // Accoya wood is virtually rot-proof Perfect for Coating Easier to coat: less preparation and sanding between coatings required//Improved dimensional stability and UV resistance improves the life of coatings//Perfect for transparent, translucent and opaque coatings Naturally Insulating Accoya wood offers improved thermal insulation in comparison with commonly used wood species//Accoya wood is ideal for applications where energy conservation is important Non- Toxic Accoya wood is non-toxic, protecting the environment from the harmful effects of poisons leaching out of typical wood treatment//Accoya wood may be safely reused and recycled From sustainable sources Sustainably sourced, including from FSC, PEFC and other regionally certified woods//Naturally renewable 100% recyclable Fully reusable and recyclable // Reuse is recommended but Accoya wood may be safely incinerated for bio-energy or composted  The technology behind Accoya® wood is based on acetylation. The physical properties of any material are determined by its chemical structure. Wood contains an abundance of chemical groups called “free hydroxyls” (represented as OH in the picture). Free hydroxyl groups adsorb and release water according to changes in the climatic conditions to which the wood is exposed. This is the main reason why wood swells and shrinks. It is also believed that the digestion of wood by enzymes initiates at the free hydroxyl sites – which is one of the principal reasons why wood is prone to decay. Acetylation effectively changes the free hydroxyls within the wood into acetyl groups. This is done by reacting the wood with acetic anhydride, which comes from acetic acid (known as vinegar when in its dilute form). When the free hydroxyl group is transformed to an acetyl group, the ability of the wood to absorb water is greatly reduced, rendering the wood more dimensionally stable and, because it is no longer digestible, extremely durable.

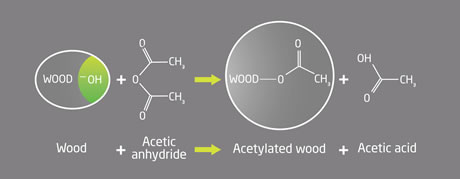

The technology behind Accoya® wood is based on acetylation. The physical properties of any material are determined by its chemical structure. Wood contains an abundance of chemical groups called “free hydroxyls” (represented as OH in the picture). Free hydroxyl groups adsorb and release water according to changes in the climatic conditions to which the wood is exposed. This is the main reason why wood swells and shrinks. It is also believed that the digestion of wood by enzymes initiates at the free hydroxyl sites – which is one of the principal reasons why wood is prone to decay. Acetylation effectively changes the free hydroxyls within the wood into acetyl groups. This is done by reacting the wood with acetic anhydride, which comes from acetic acid (known as vinegar when in its dilute form). When the free hydroxyl group is transformed to an acetyl group, the ability of the wood to absorb water is greatly reduced, rendering the wood more dimensionally stable and, because it is no longer digestible, extremely durable.

http://www.accoya.com/