The aim of the exercise was to design through digital fabrication, a facade or skin of a WikiHouse : the architectural element that act as a mediator between an exterior public space and an interior private space. Digital fabrication techniques allow us to design and fabricate intricate material system that incorporate performative solution mass customized to shape, orientation and context. The challenge was to design the facade with the technique of wood bending and acrylic, with wood being 15% and the acrylic being 85% of the overall composition of the facade.

CONCEPT

We defined a structural system based on the use of acrylic as a vertical structural element as well as a bending agent for wood. Wooden strips horizontally constrain acrylic pieces and attach this system to the frame. This has deeply influenced the shape of facades components, which can potentially vary in vertical dimension to affect the shading of solar radiation. Solar shading can also be influenced by the width variation of wooden strips. By varying the pattern of transparent and translucent acrylic elements, the quantity and quality of light transmission can be controlled

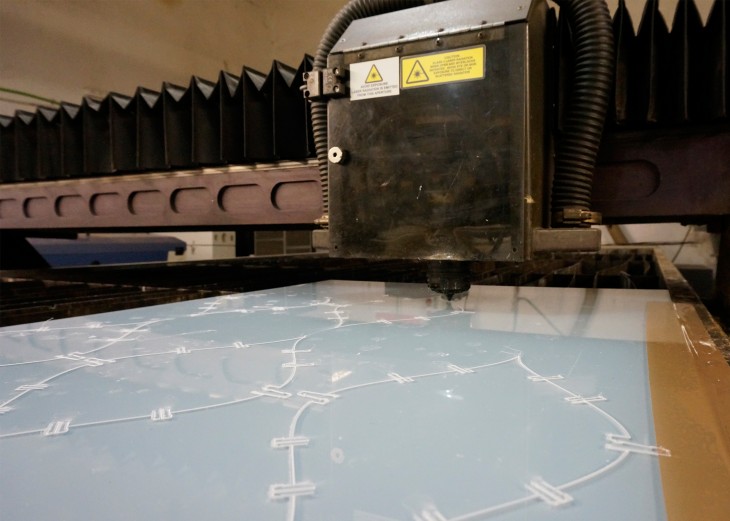

The engraving of lines for kerfing

The laser cut machine cutting the acrylic

Joinery Tests done

assembling the facade

The Wiki house facad

METHODS

Initials tests were focused on bending wood. The first attempt was based on the use of steam to bend a 4mm plywood stripe and make it flexible. High temperatures affected the glue, so we moved towards a thinner wood solution, but 1 mm wood was not strong enough to be paired with a rigid material such as acrylic. Finally, we found another way to bend 3 mm and 4 mm plywood using the Kerfing technique. We selected a specific pattern among many because this allows the wood to bend and deform in one direction, the one that we needed. We did several tests by scaling the pattern in different ways on 4 mm and 3 mm plywood, and we ended up using the 3 mm wood. The wood were cut in 35 mm wide stripes, each one with 11 holes to fit acrylic joints in. In order to lock the connection acrylic-acrylic and acrylic-wood, we studied three different typology of clipping pins, according to position in frame. We chose 4 mm acrylic because the original intention was to mill it with different patterns, in order to modify transparency. While assembly all components together, we noticed that the medium joints were too long to permit an easy mounting.

Digital Fabrication | The Wiki House Facade is a project of IaaC, Institute for Advanced Architecture of Catalonia developed atMaster in Advanced Architecture in 2015 by:

Students: Connor Stevens, Fulvio Brunetti, Rana Abdul Majeed & Varsha Subba Rao

Faculty: Alexandre Dubor