CONCEPT

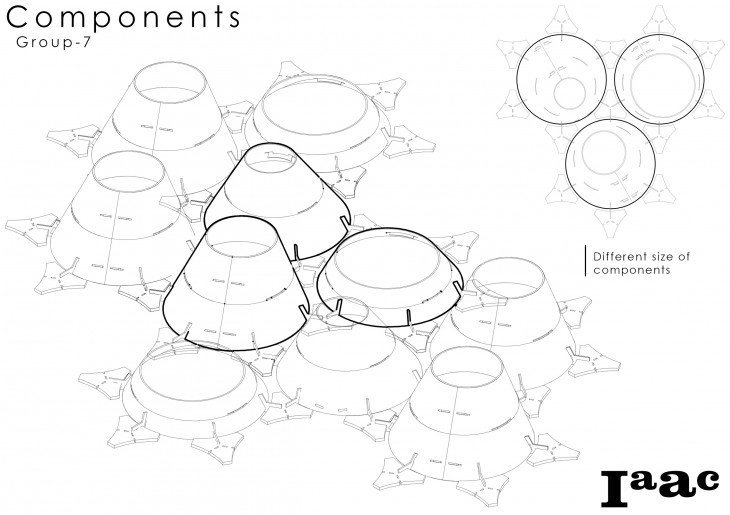

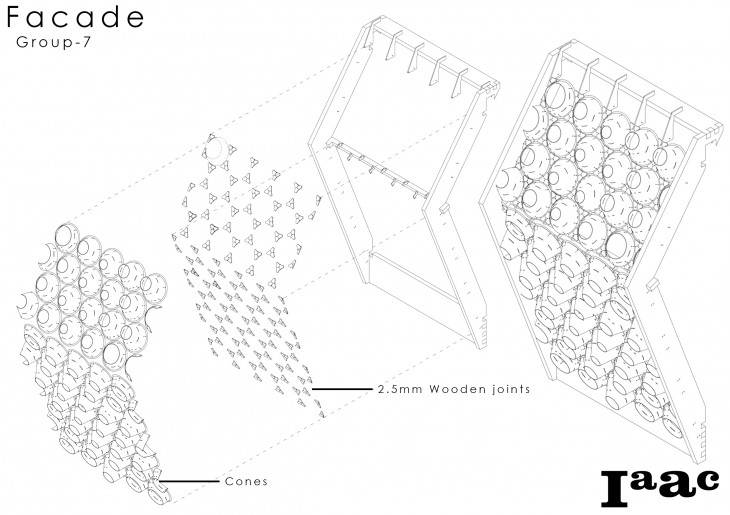

The concept of this facade involves bending wood and incorporating polypropylene to create a sturdy yet sustainable structure. Our design consisted of 3 different size sets ofcone shaped wood and a variety of joints that perform as union as well as support. All ofthese leading us to a structure, that will not only have a combination of materials, but mostimportantly, it will give us, light, heat, and protection for the wiki-house.

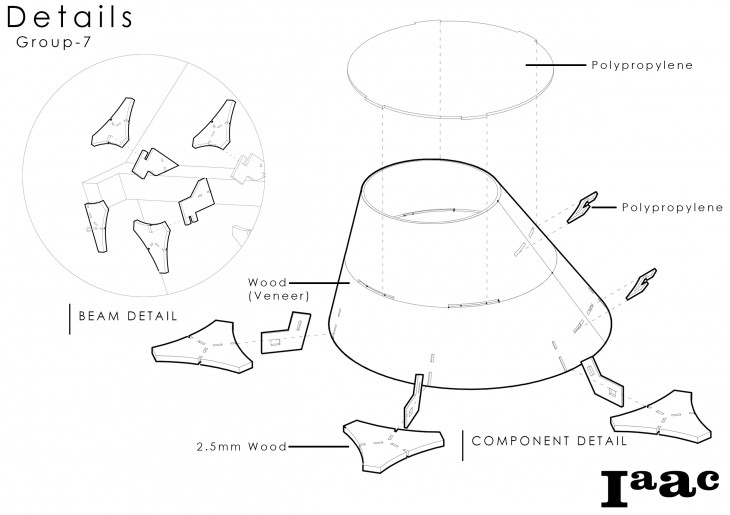

The idea behind using Veneer (wood) as one of our main materials was to use a thin medium and transforming it to make it stronger. The flexibility of the veneer, allowed us to shape it into a cone. Then, the combination of the wood with a stronger material such as plywood and polypropylene gave us the perfect method to make the structure of the facade sturdier. The joints are placed in strategically places to create zero movement among each connection avoiding motion among the facade. Each joint and cone include sets of gaps, however, the gaps not only serve as joint placeholder but also help in allowing light to come into the house.

Inside each cone, a circular shaped polypropylene piece was placed for sun and water protection. The use of the translucent material inside the cone helps to transfer light, as well as to transfer heat from the sun. This also helps in avoiding water and/or other objects to go inside.

METHOD

To obtain the cone; the wood was laser cut a 70% of speed and 250% of power, each cone included gaps strategically placed among the surface to serve as place holders for the joints. The joints were cut the same way however in order for us to obtain great results, the power and speed were altered. For 1 mm polypropylene (joints used to close the cone) the speed was at 70% with 25% power. To cut 2.5 mm plywood (joints used to connect between cones) the speed was at 50% with 360% power.

However in using the laser cut for the polypropylene the material melted and it glued back together, we had to change the speed and power to not cut through the material to avoid shape deformation. Later, to obtain the shape, we had to cut manually. The sizes of the cones were the key factor in creating the shape of the polypropylene joints.

Each set of joint has a different angle, which fits around the circumference of the cone. Then, placing the plywood joints did the connections between the cones. These joints were shaped in a triangular form to obtain a connection among 3 different cones.