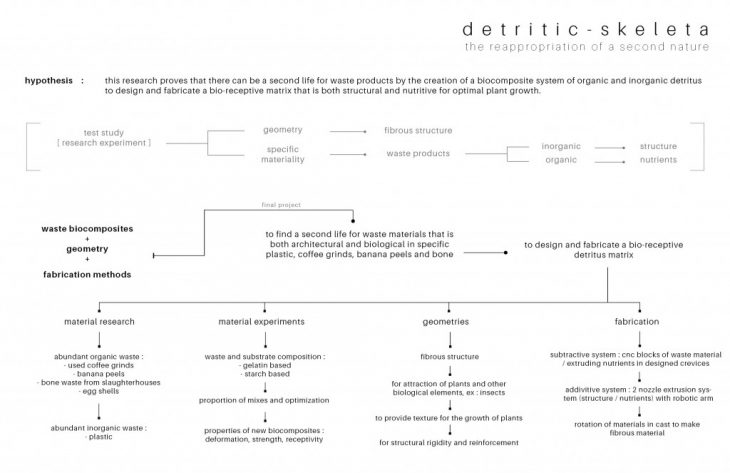

Detritic Skeleta : The Reappropriation of a Second Nature

Student : Johana Monroy

Tutor : Marcos Cruz

Computation Tutor : Rodrigo Aguirre

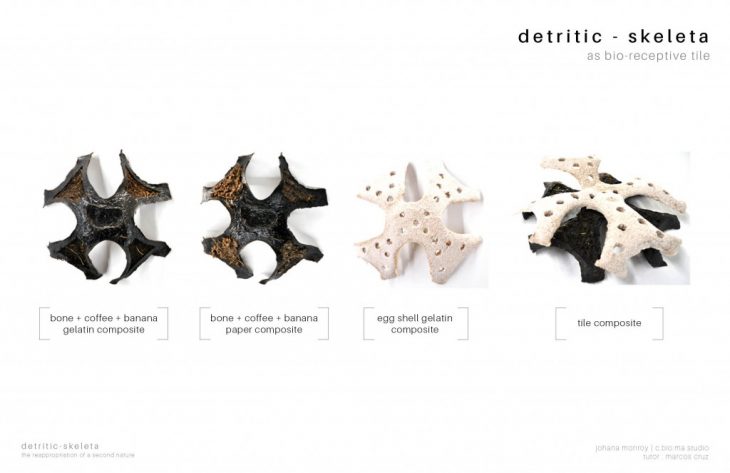

Detritic Skeleta is a research based on the re-appropriation of waste with its essential question being, “Can waste have a second life as a nutrient based material for architectural purposes?” After material exploration and experimentation, focusing on the waste products of bone and eggshells, the goal has been to find an adequate manufacturing method for said waste material. Geometrical analysis has followed hand in hand with such experiments to get the material to a degree of manipulation that would dry and prevent deformation while reaching it optimal strength and desired geometry.

Beginning geometry focused on casting methods which focused on soft and hard mediums. Some components were casted in latex, giving the geometries some deformities while others were casted in wooden moulds.

Later, the idea of extruding the material arose and several geometries studies and physical prototypes were produced.

The final method of fabrication is a combination the 2 previous studies where the material matrix is extruded on a mould to prevent shrinkage while drying while reaching the desired geometry.

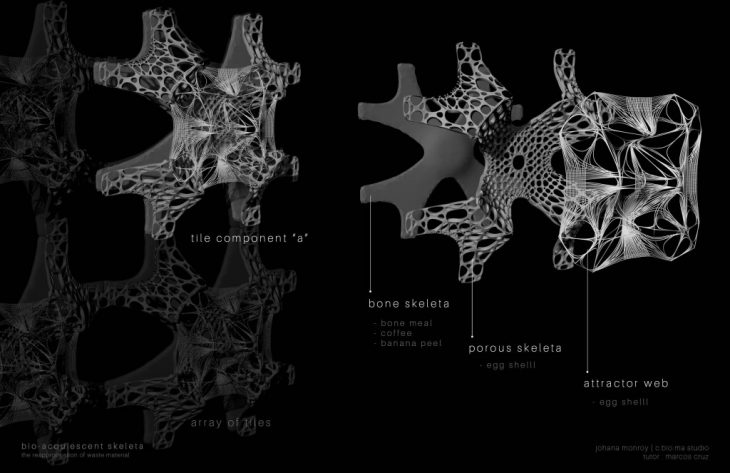

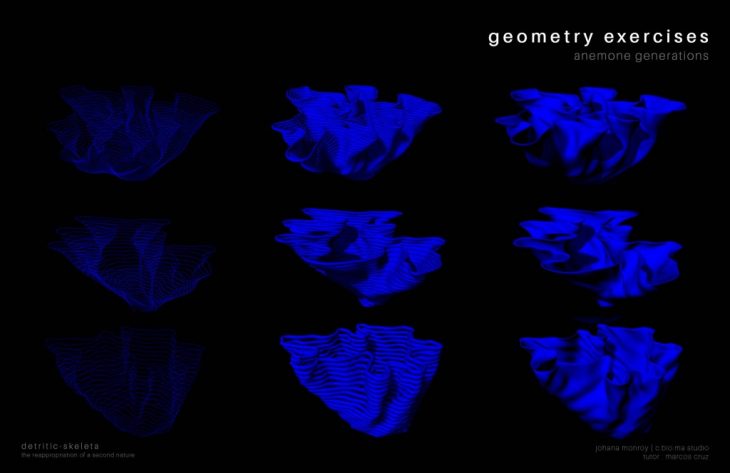

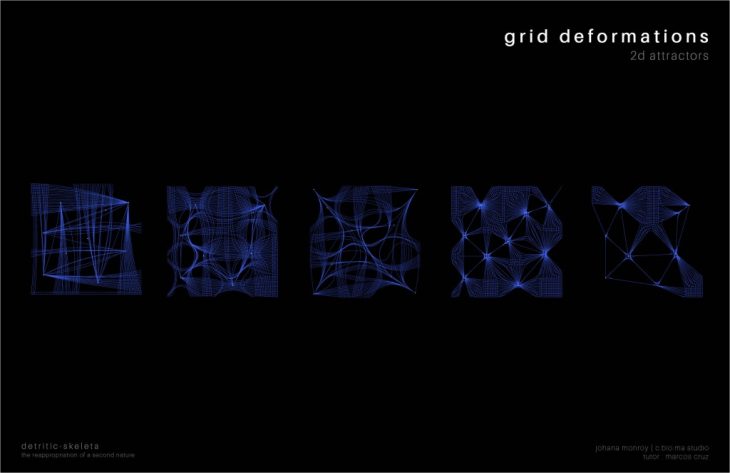

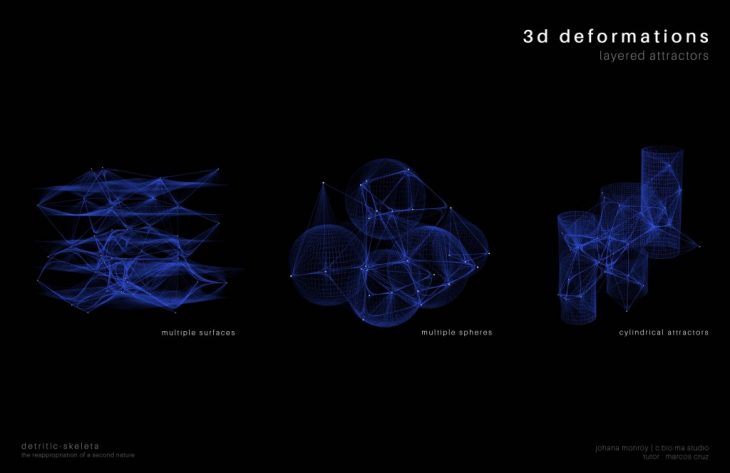

The system developed through Grasshopper and Rhino was a series of grid deformations through the use of attractor points, each having different positions and strengths.

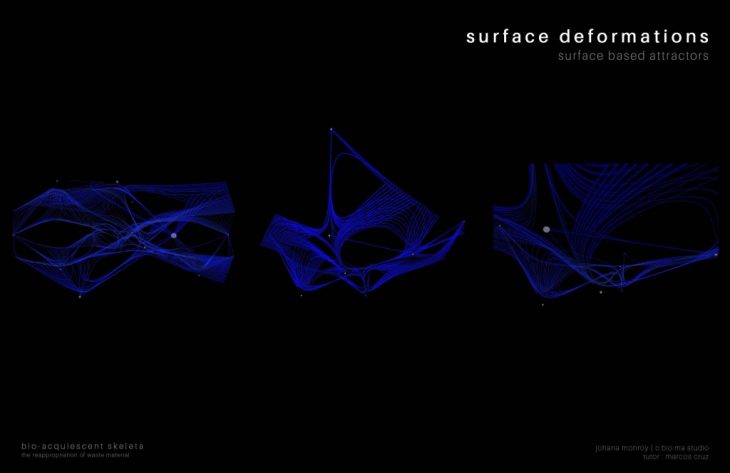

The first series of attractor based geometries were focused on single surfaces that would deform in time to create 3 dimensional spaces.

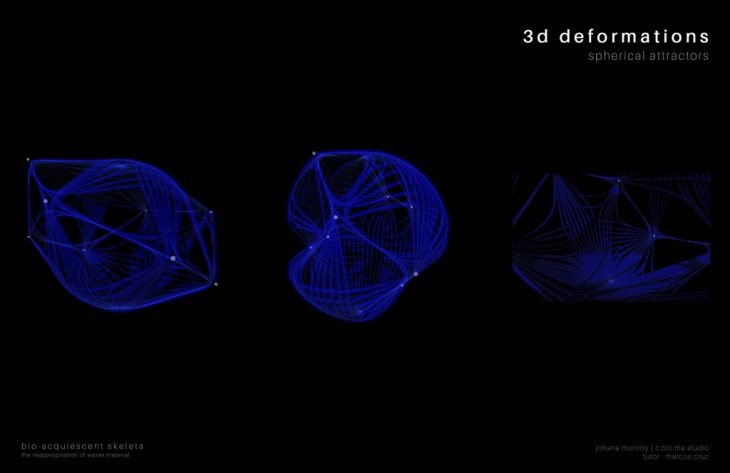

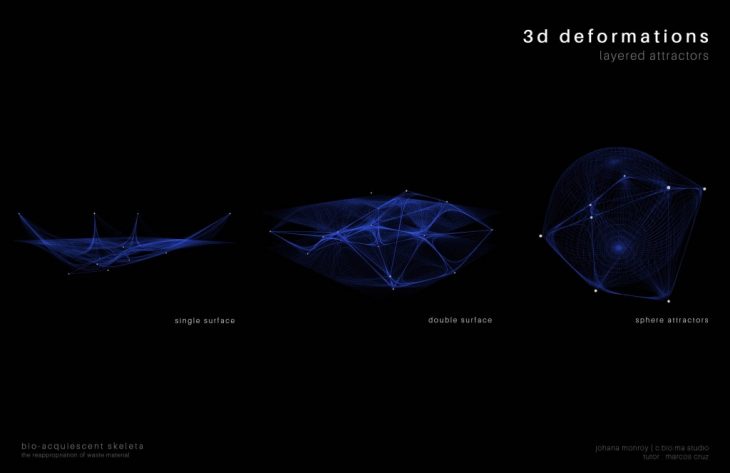

The same logic of attractors was taken into multiple surfaces which interacted with each other to create more dynamic spaces.

The final prototypes followed the same grid deformations where the material was extruded on a pre-made cnc foam mould.

Manufacturing Process

The ultimate goal of this research when it comes to computation and fabrication processes is to develop a system where the robotic arm will extrude the organic material producing large prototypes for the use of agricultural purposes, providing plants with required nutrients, while the produced structure vanishes in time.