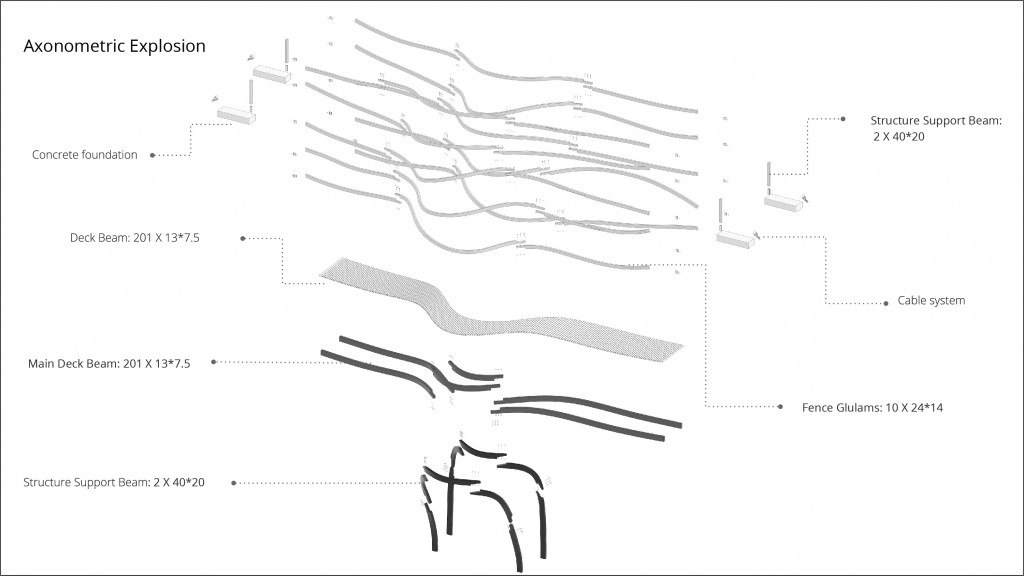

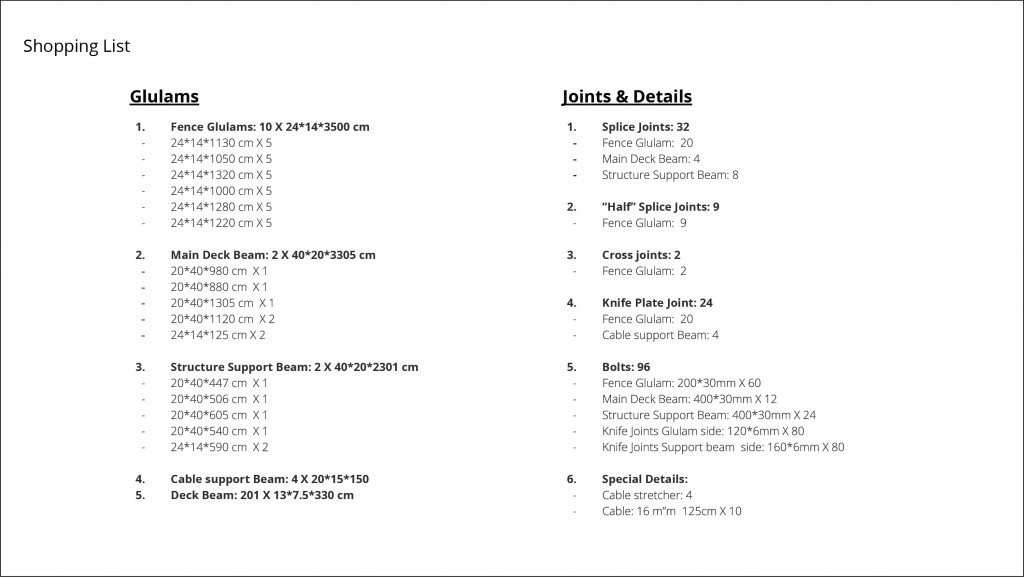

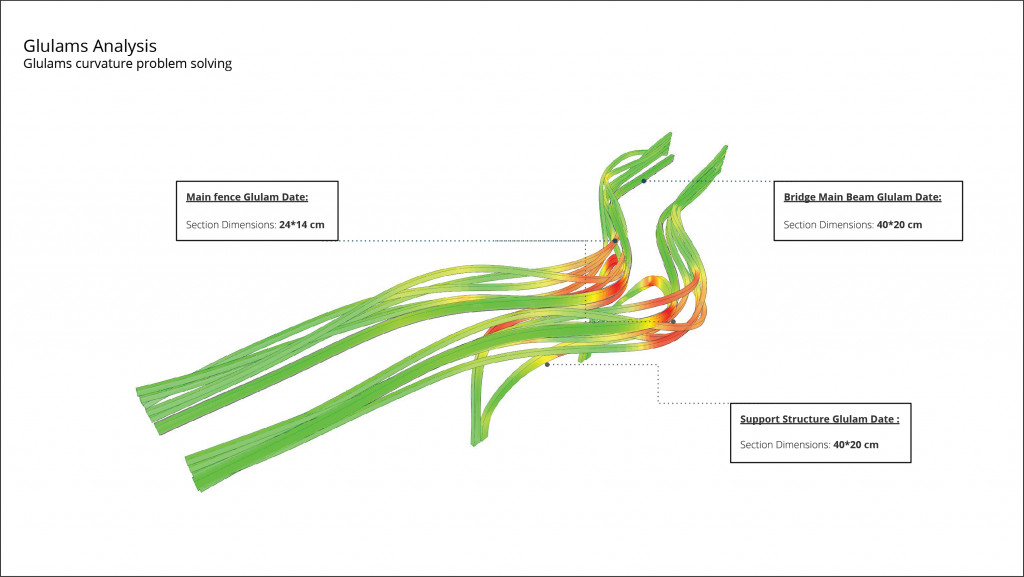

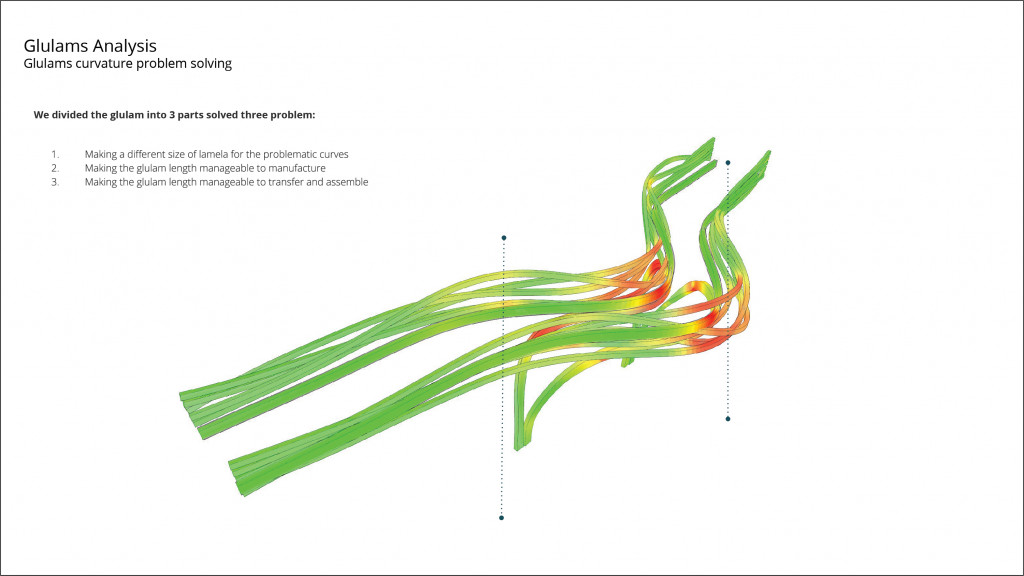

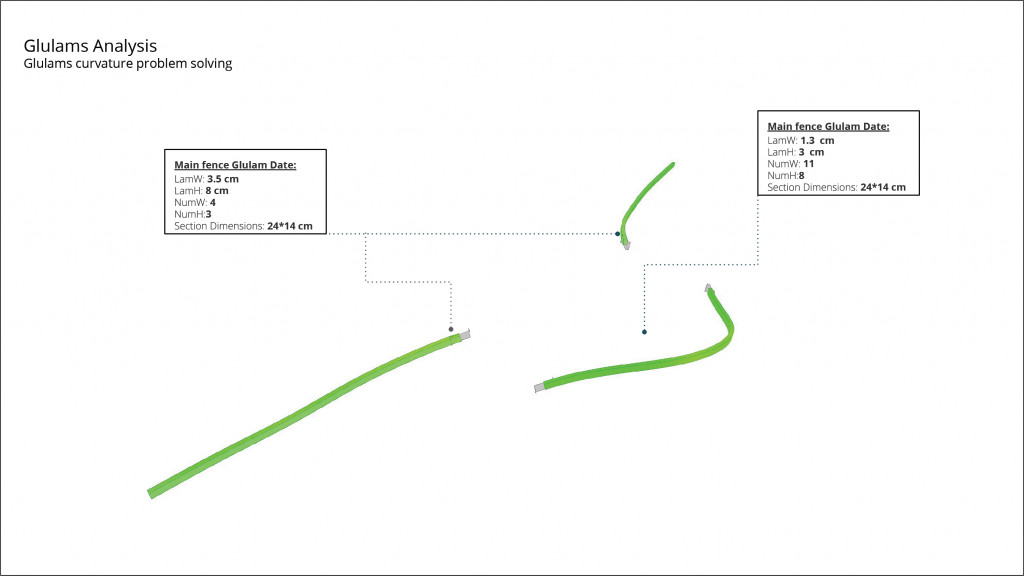

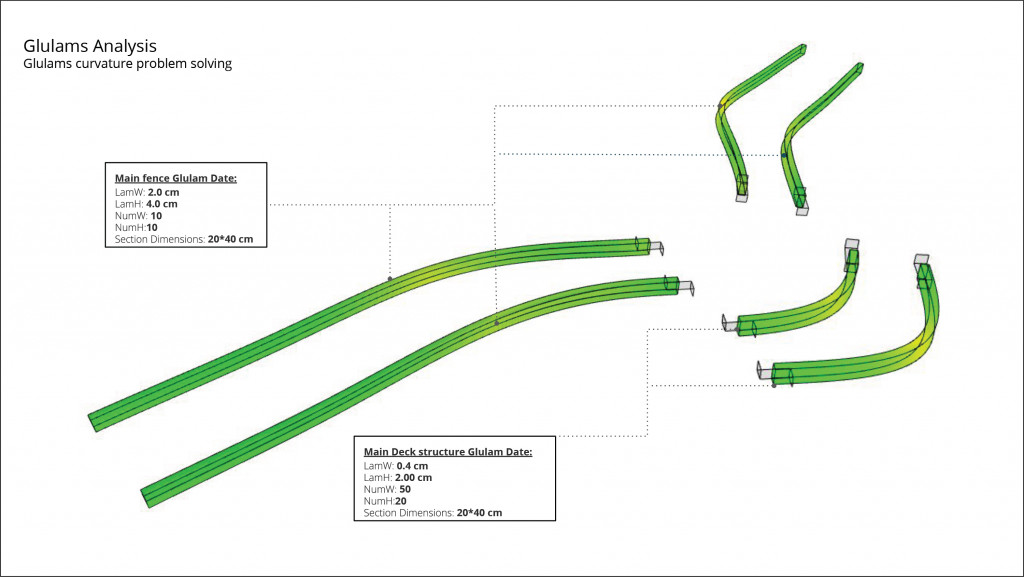

“Curvas” is a Wooden bridge, all constructed by using “Glulam” wood technology.

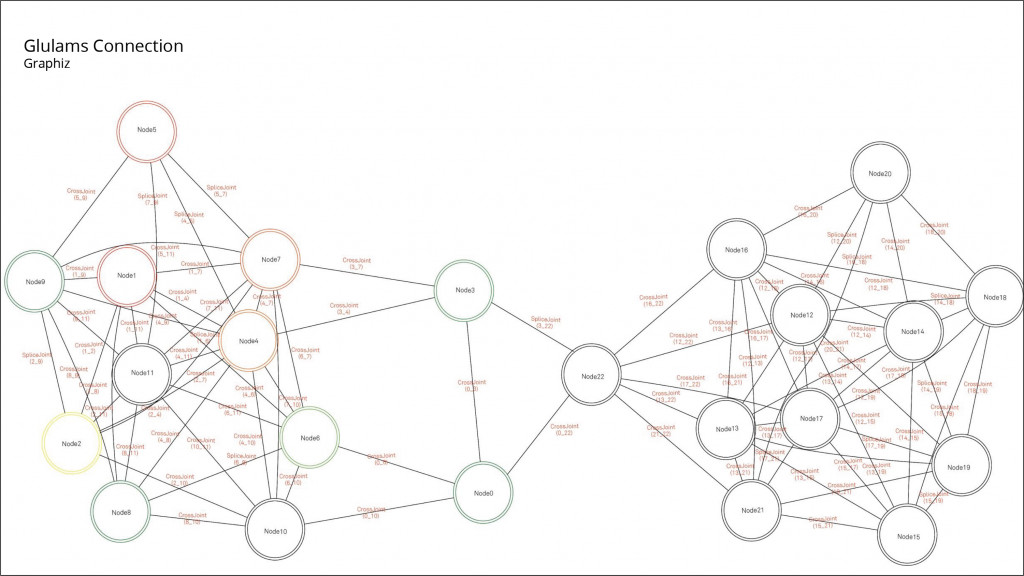

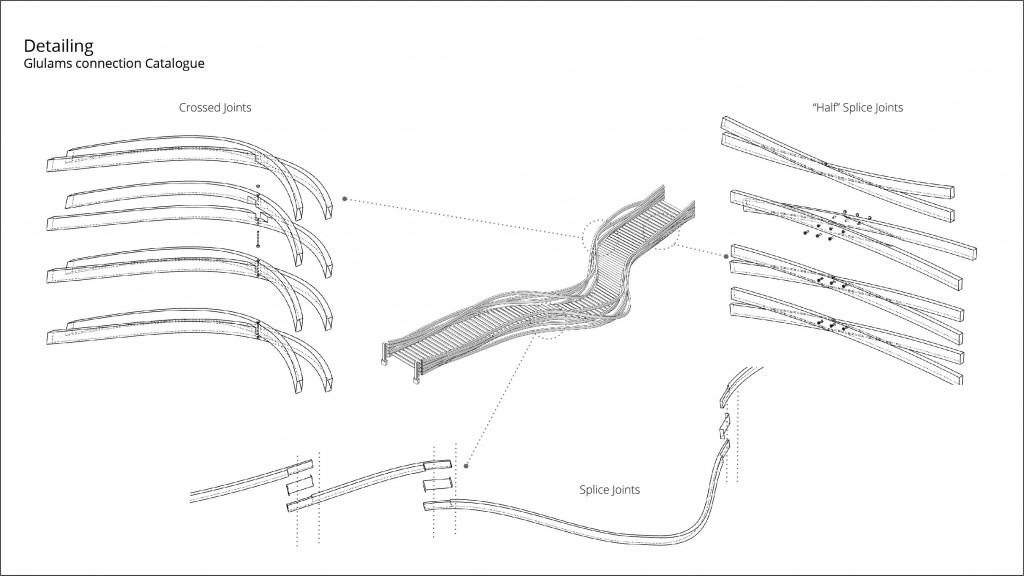

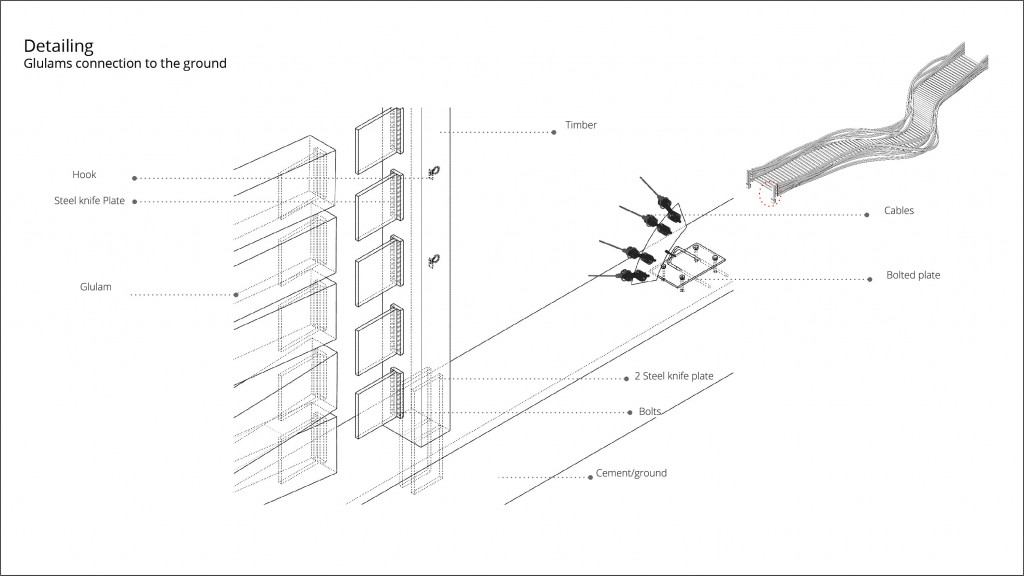

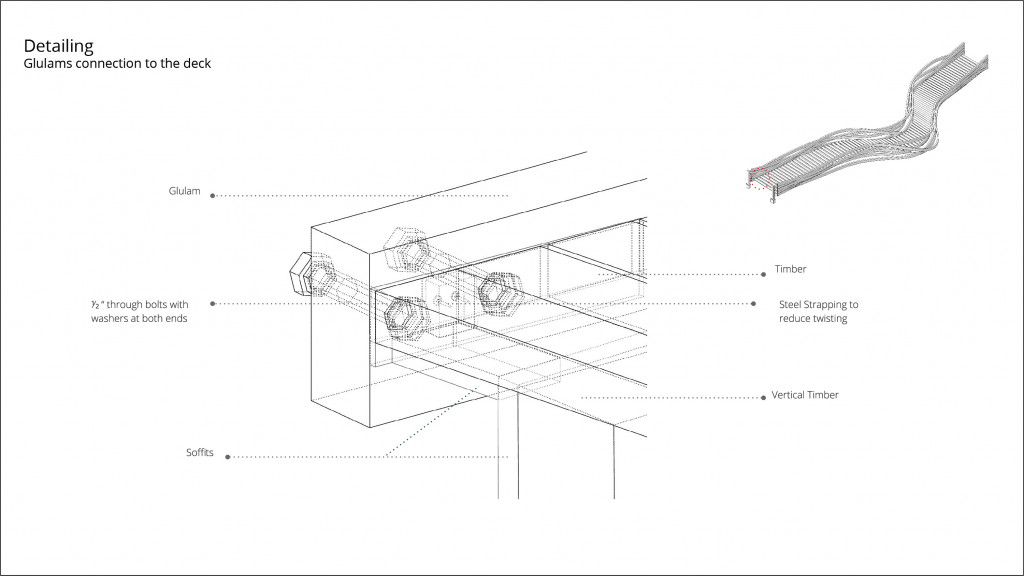

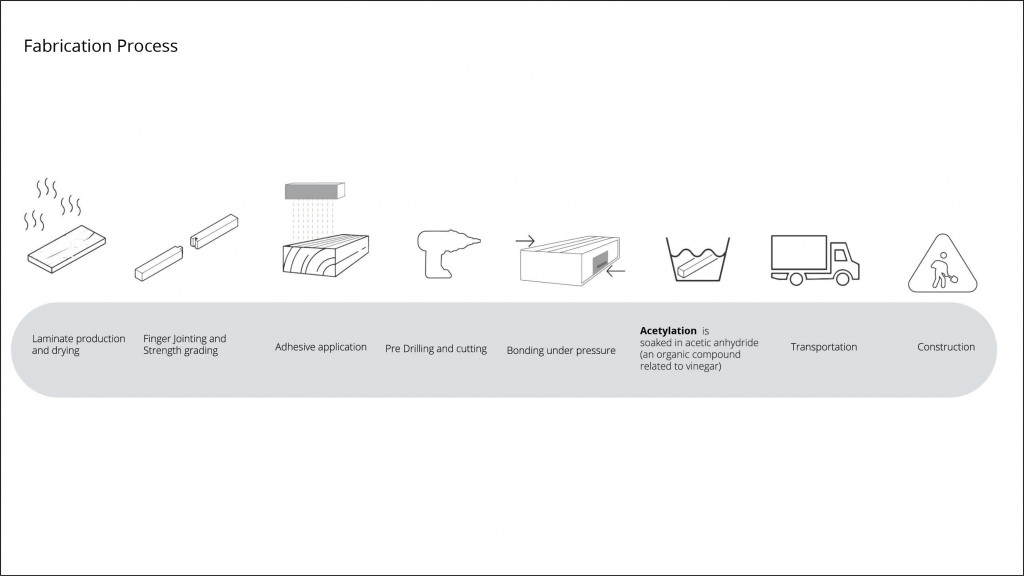

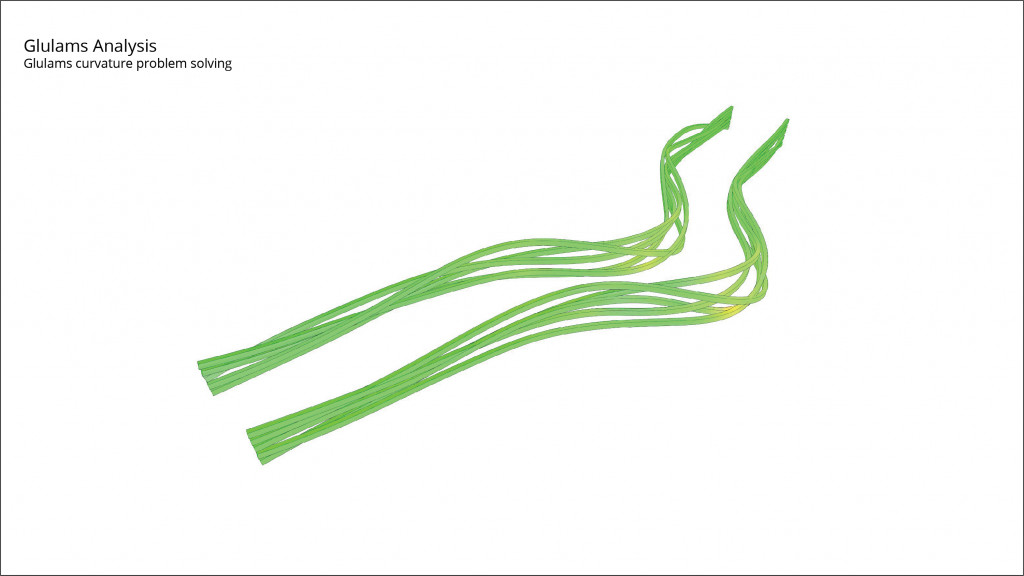

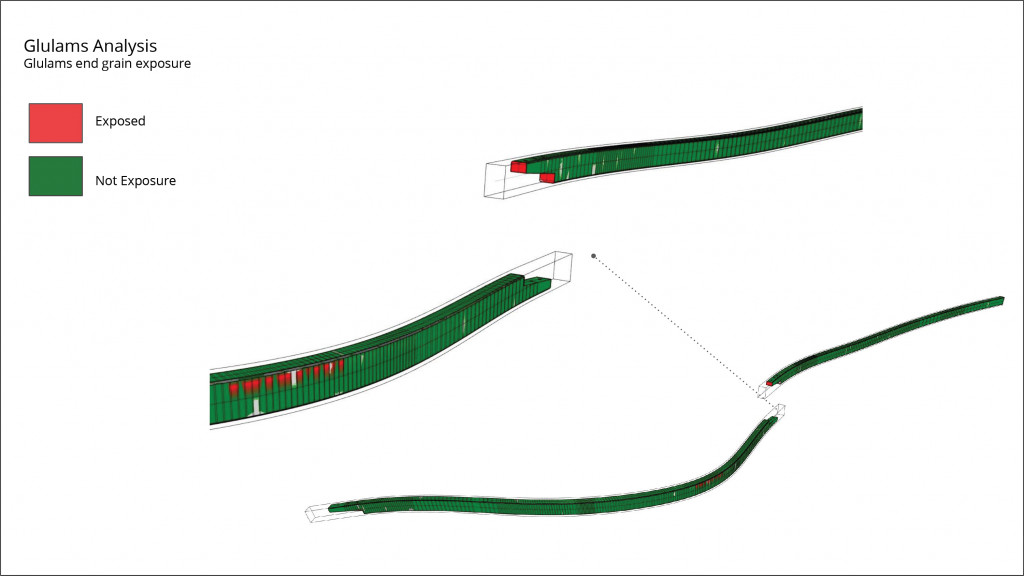

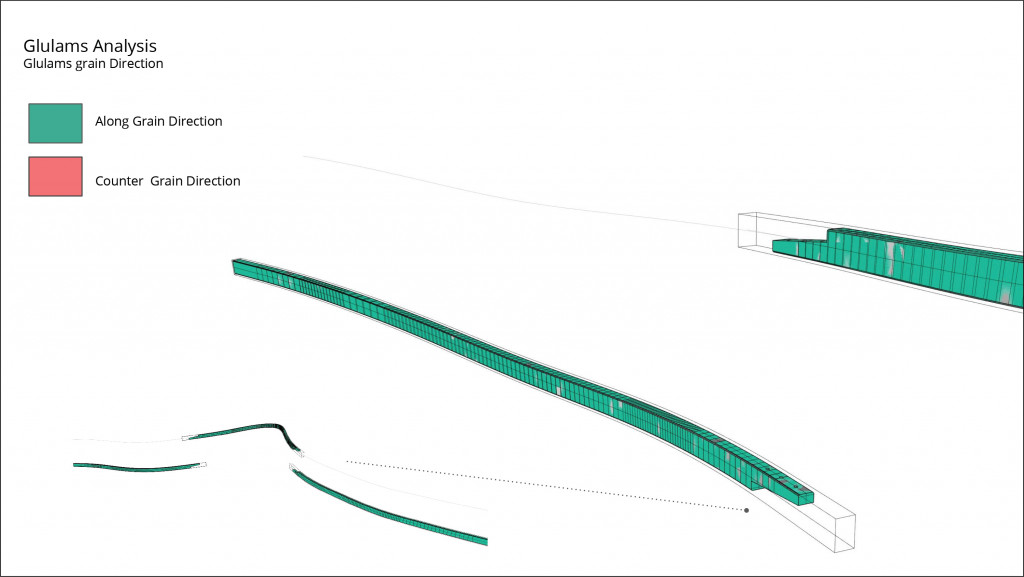

Glulam is Laminated wood, bent and curved by CNC machines. The entire bridge was designed in Grasshopper Using the plugin “Tas” by Tom Slivans.

Glulams unable us to build complex wooden forms and structures.

</p>

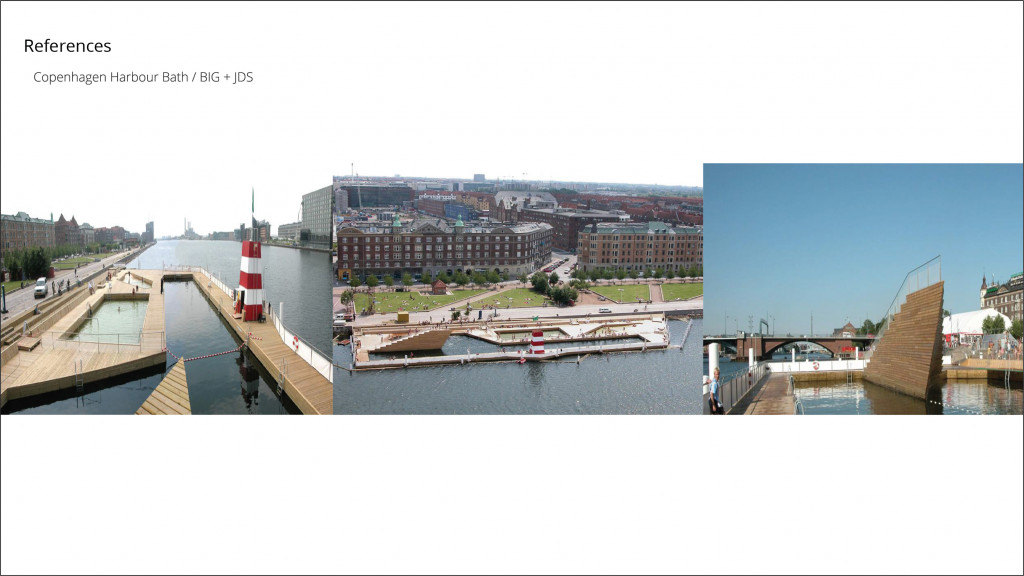

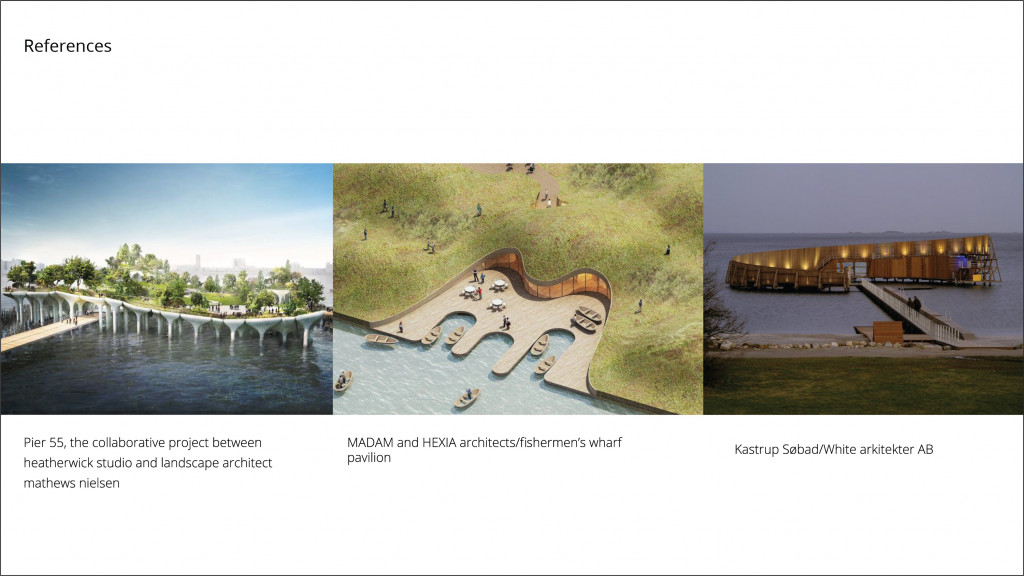

The project started by a research for a program and a references for the design

We have decided that our program is a Peer or Bridge and that we want to use the material and technology features and take it all the way to their extreme.

We wanted to produce a real project that we could produce at the end of the course.

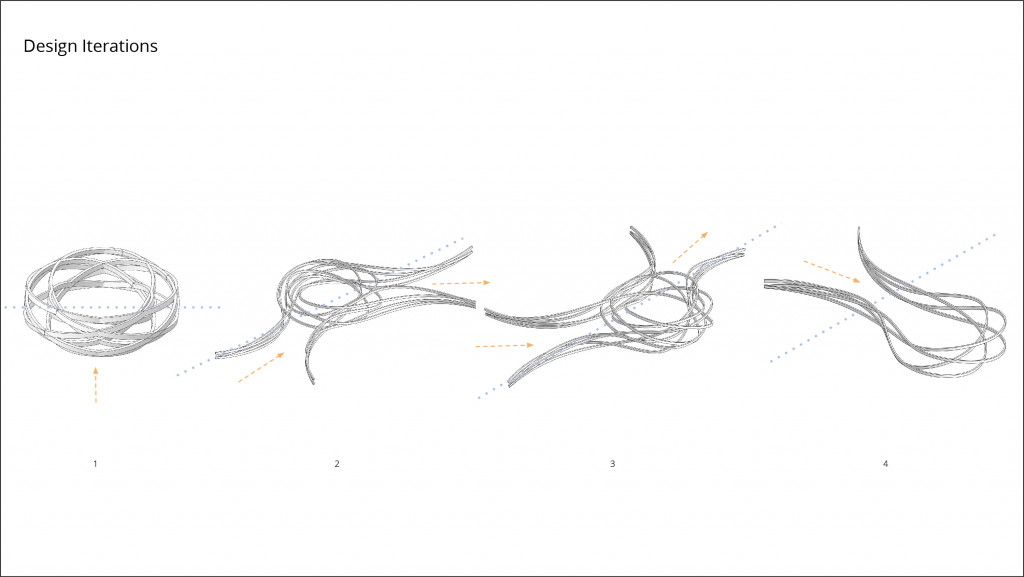

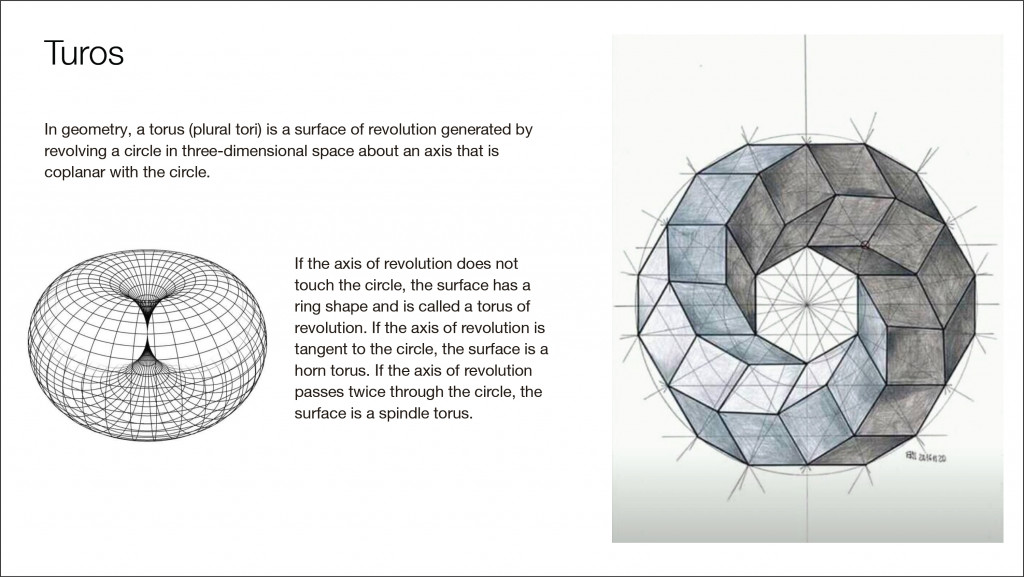

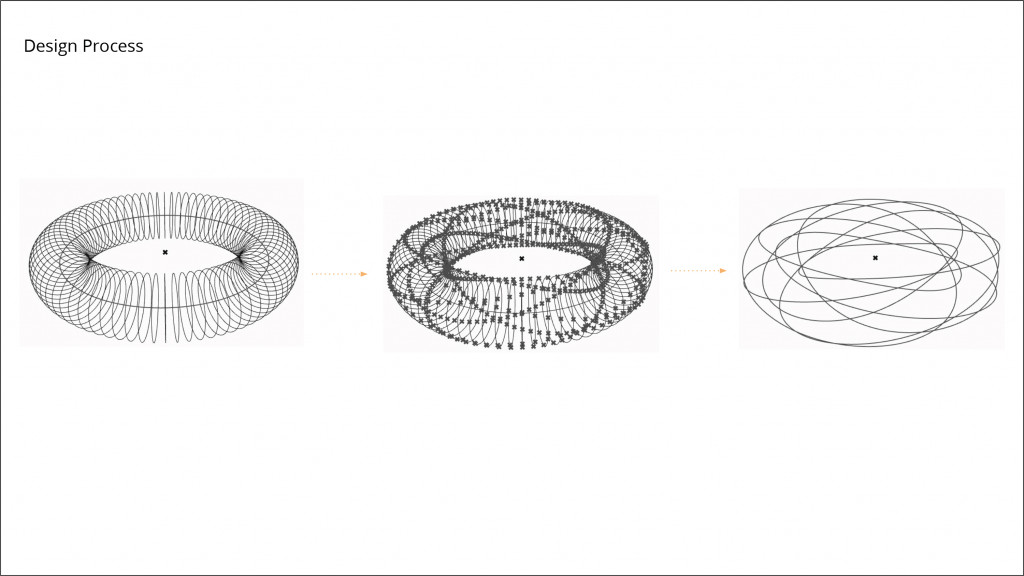

We chose the concept of the “Turos“shape, as it contains many circles that can produce a base for a interesting curve system to drive the design of the bridge

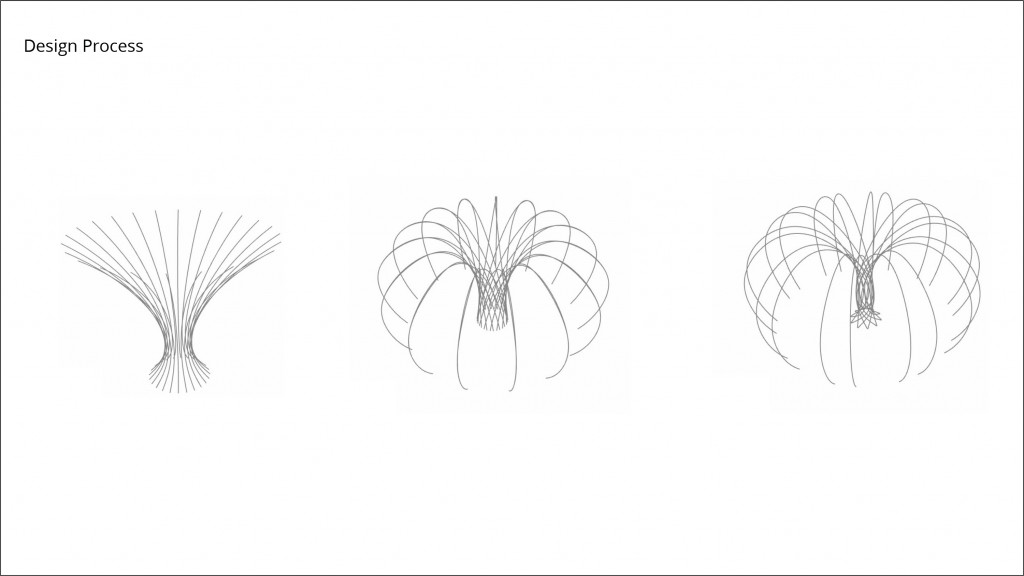

We began to play with the curves of the torus and divide them until we got to the following shapes:

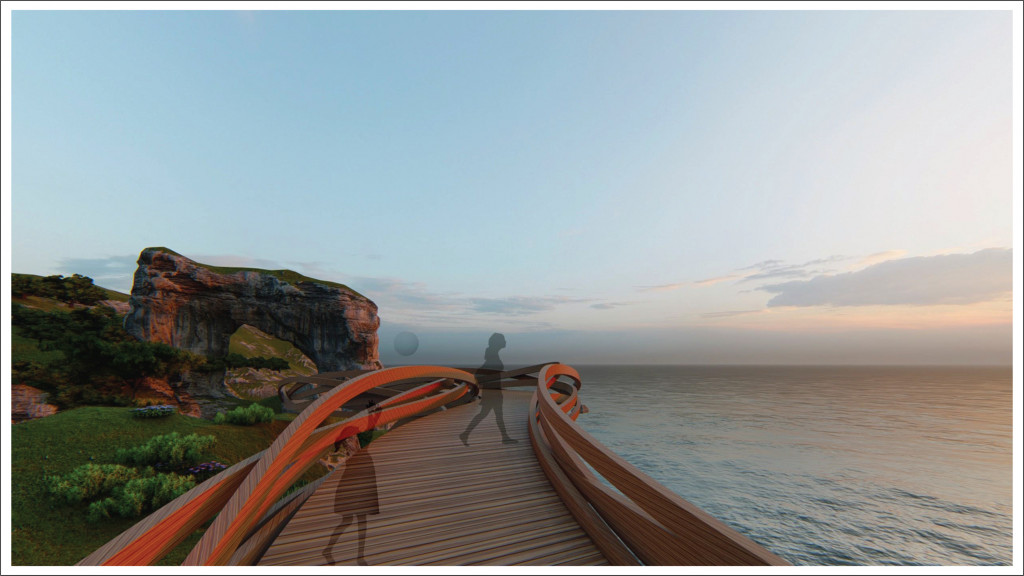

After getting the shape we wanted, we were testing and trying to understand what the flow of people would be on the bridge and how it goes out and penetrates the shoreline into the water