COMPUTATIONAL DESIGN FOR ROBOTIC FABRICATION

Faculty: Alexandre Dubor

Faculty Assistants: Ricardo Mayor

Credits: IAAC MAA01 Robotic Seminar

Credits: IAAC MAA01 Robotic Seminar

SYLLABUS

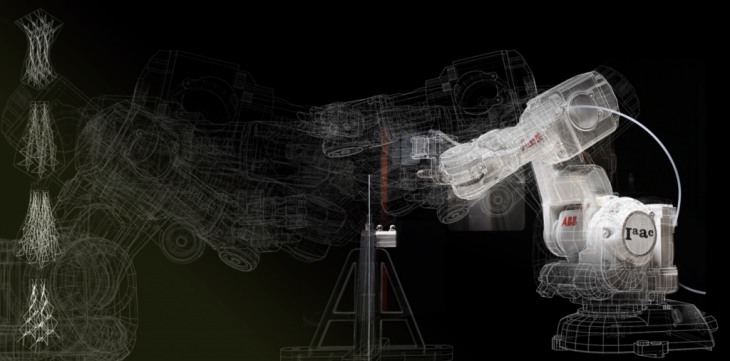

The current trend of Industry 4.0 promises groundbreaking technologies such as robotics, accurate sensing, computational design, AI and cyber-physical systems that can potentially transform the way we design, build and inhabit, tomorrow. How will we integrate these new technologies into the creative development of design and architecture? What are the new material tectonics revealed by robotic technologies? How can we optimize, analyze or simulate the physical requirements of our fabrication process through our digital environment?

This seminar proposes to explore a series of digital design methodologies, including robotic simulations to explore the potential of optimization for physical robotic fabrication through digital means. The unique combination of digital simulations and fabrication in robotic manufacturing opens up new paths on novel architectural morphologies.

Students will explore new topologies via handcrafted models before digitalising and emulating the fabrication process with an industrial robotic arm. Feedback from robotic simulation and material simulation will be integrated into a multi-objective optimisation allowing students to negotiate design, fabricability and performance into one integrated design process. The final outcome will be from one side a robotic fabrication simulation (that could be run at IAAC) demonstrating the feasibility of the proposed morphology,, and from the other side, a render of a well-articulated architectural facade that demonstrate the design and performance potential of the proposed process.

LEARNING OBJECTIVES

At course completion the student will:

- Understand the basics of robotic kinematics, robotic simulation and robotic control;

- Have an overview of the possible robotic fabrication processes available for architects and designers;

- Be capable of designing an architectural project, where robotic fabrication is used to produce the final outcome;

- Be capable of generating the robotic simulation and production files to produce a prototype;

- Be capable of integrating the limitations and opportunities of a specific robotics process into the final architecture design, and negotiate the different variables through optimisation algorithms.

FACULTY

Alexandre Dubor is an architect expert in digital and robotic fabrication currently working at IAAC as researcher, teacher and project manager in R&D. He studied architecture and engineering (March. ENSAVT / ENPC, March. IAAC) and have worked in the past at Studio Libeskind, Atenastudio, iDonati, AREP and Appareil. He’s a multidisciplinary designer exploring the potential raised by digital tools and new materials for the improvement of the built environment. He is now leading the Open Thesis Fabrication program as well as the Master in Robotic and Advanced Construction at IAAC.

Ricardo Mayor is a Master in Architecture Superior Technical School of Architecture of Alcalá de H. in Madrid and a Master Degree in Advanced Architecture from IAAC (Spain). He graduated in 2012, obtaining a prize for his academic results and a further one for his final project. Since then he is one of the four founders of Design of Architectural Territories – DAT Pangea – who was awarded the first prize for the Best Young Architects in Europe for their Sustainable construction by LafargeHolcim Foundation. His working career has been mainly developed in architectural and engineering offices in Madrid, Paris, Ljubljana and Barcelona, taking part in internationally recognized projects with architects as OMA, Frank Ghery, Jean Nouvel or Kengo Kuma.