Claycelium

Claycelium is a project developed at IAAC, Institute for Advanced Architecture of Catalonia, in collaboration with IIT, Italian Institute of Technology. Claycelium was created by Justin Sheinberg and Mert Gonul during the 2018/19 MAA01, Digital Matter program. The Digital Matter studio theme was to create a material that contributes to the field of performative architecture. As time moves forward we can no longer have architecture that is static, it must become alive and be able to adapt to our ever changing environment and societal needs. This is due to the fact that today our society and architecture are facing new challenges. Physical spaces and digital technology are becoming interconnected. Architecture has become more of a computerized machine that performs interactive tasks which benefit the users or the environment. Some of our greatest threats in the 21st century are economical instability, agricultural production, global urbanization and an environmental crisis. The next era of architects need to address these developing threats and understand the significance for the need of performative architecture.

Claycelium is a research project with an interdisciplinary approach, combining areas such as material science, computational design, architecture, agriculture cultivation and robotics. The objective of the research is to increase the structural properties of clay through means of natural living reinforcement and to use this composite material as a way to create food producing architecture. We did this through the use of Mycelium, the vegetative part of a fungus consisting of a network of fine white filaments.

In the beginning we looked for a biodegradable, natural and locally sourced materials that would impact our environment in positive ways. Keeping this in mind, we began to research mycelium and asked ourselves the question; Can mycelium be used to increase the structural properties clay and proved the means for agricultural production.

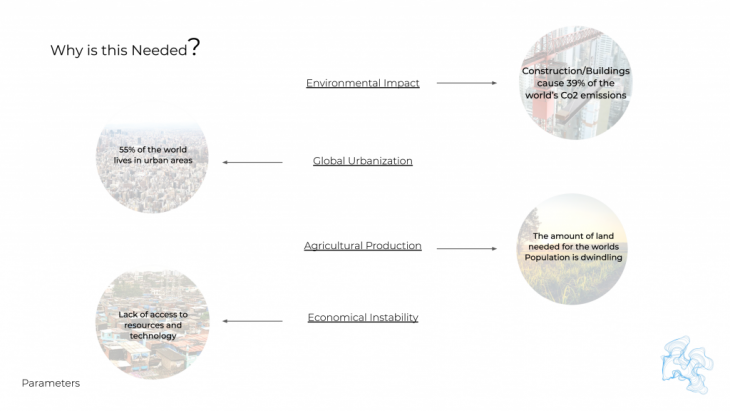

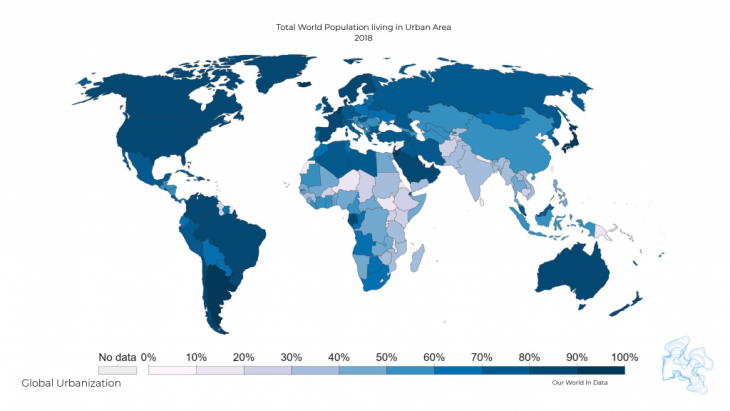

Some of our greatest threats in the 21st century are the environmental impact of construction/buildings; which causes 39% of the world’s Co2 emissions, Global Urbanization which is rapidly growing from 55% of the world’s population living in urban areas to 75% by 2050. With the large number of people living in urban areas the demand for agricultural production increases, even though our land is dwindling. The next era of architects need to address these developing threats and understand the significance for the need of performative architecture.

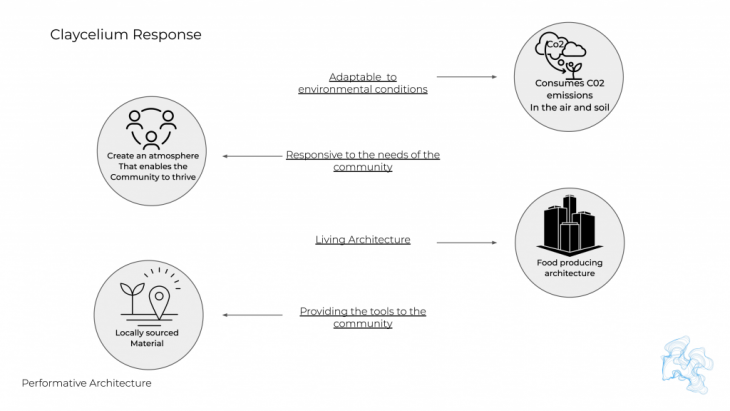

How can we as architects respond to this? As time moves forward we can no longer have architecture that is static, it must become alive and be able to adapt to our ever changing environment and societal needs. Claycelium is a material composite that absorbs Co2, and other contaminants, from the soil, air and water. It responds to the needs of the growing urban community by providing them with food, shelter and a knowledge. Of cultivation.

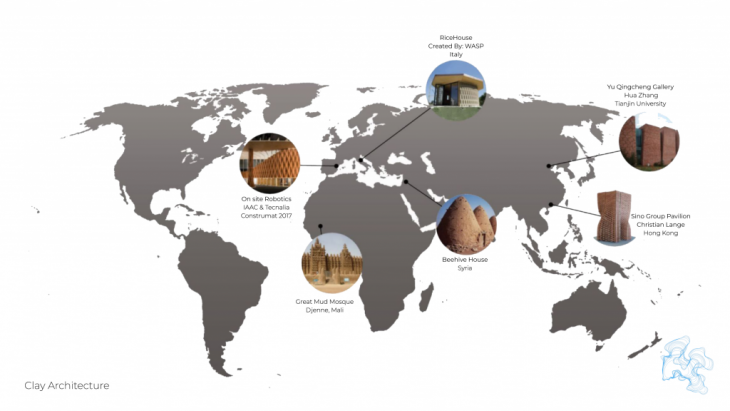

Clay as a building material has been used for walls, facades, roofs, terraces and furniture for centuries. This is due to fact that clay has excellent insulation properties and heat storage capacity and it can reduce the energy consumption of structures. However, today it has the reputation of being associated with only traditional and underdeveloped areas.

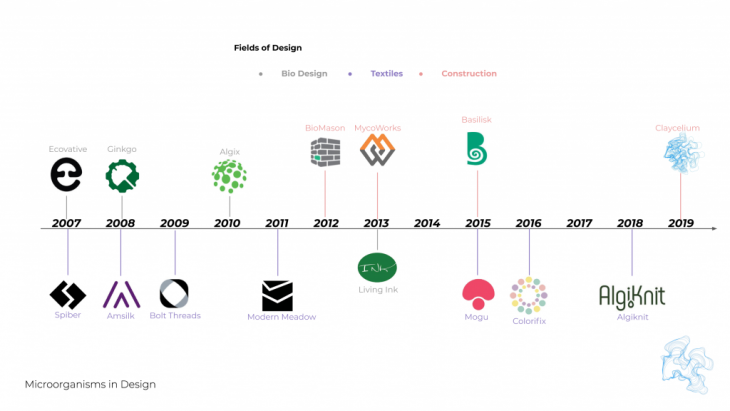

Microorganisms in Architecture is not a new concept. There have been and are currently are companies/universities researching the potential of these organisms in design. In these state of the art projects mycelium and other living organisms were used to test nature as architecture.

In my experience as an architect, we are generally a little slow to the game. It took architects years before involving CAD software in design. As you can see here since 2007 biomaterial design, Textiles and Construction companies are incorporating living natural material into their products; whether that be in packaging, clothes or even printer ink.

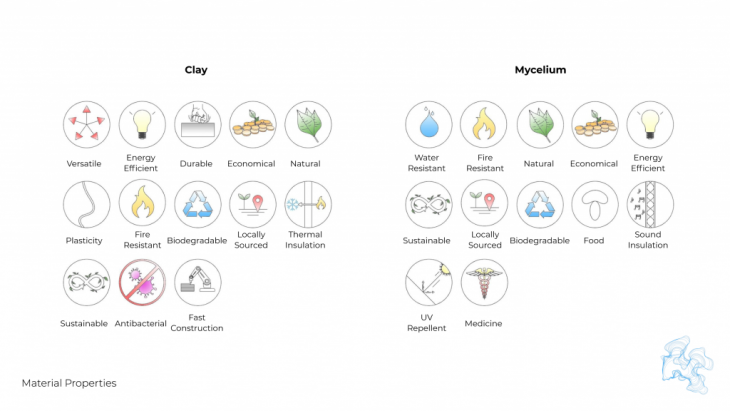

Looking at the properties of clay, a typical building material, and mycelium, the living fiber network connecting our plant life around the world, we can see a symbiotic relationship between the two materials.

When we combine mycelium and clay we create a composite with material properties that meet our research requirements. It is all natural, locally sourced, durable, economical and has the ability to be used in architecture.

However, if you wish to keep these properties of claycelium then their are certain environmental conditions that need to be maintained. When working with mycelium it is good to try and keep the area as clean as possible. This means using gloves, respirator and cleaning the tools with isopropyl alcohol. Once the claycelium is constructed the material will need to be incubated to allow the mycelium to grow. We have found that keeping our grow tent between 20-28 degrees celsius and 70-90% humidity we were able to grow mycelium throughout the clay.

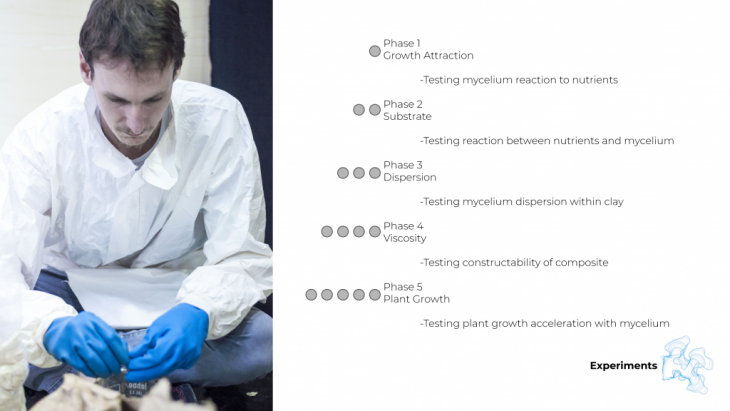

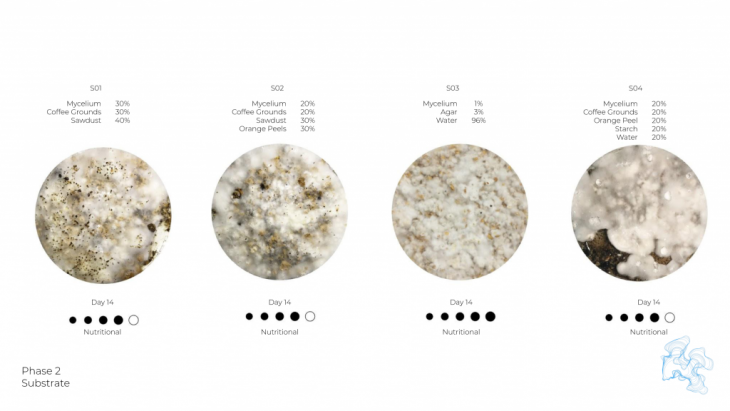

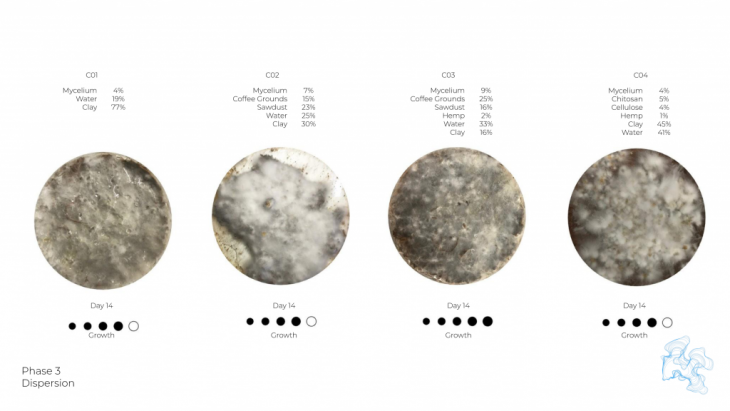

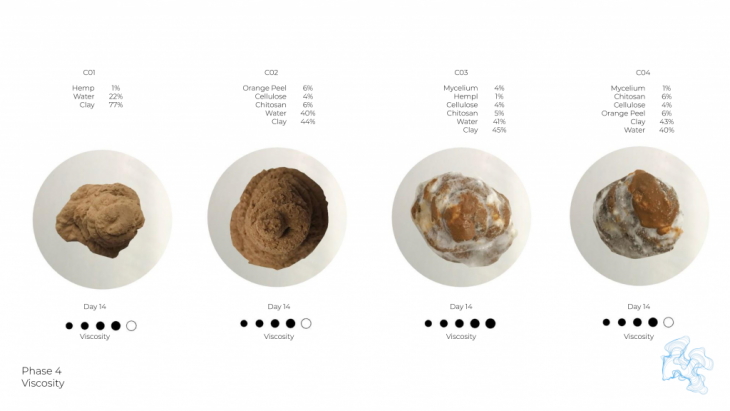

We began with five phases of experiments; growth attraction, substrate, dispersion, viscosity and plant growth. These experiments tested the optimal nutrients for accelerating growth of both mycelium and plant life.

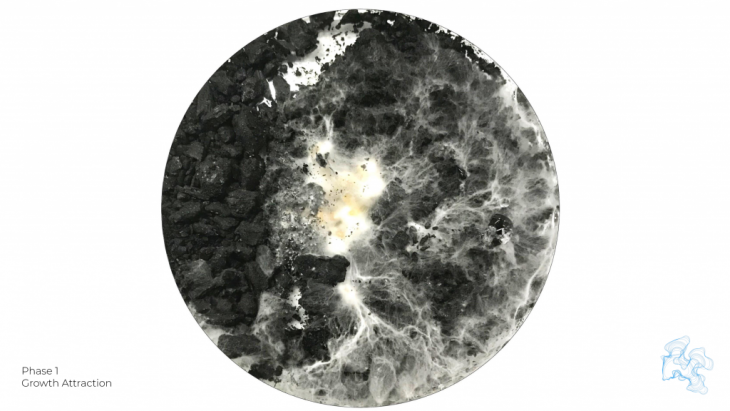

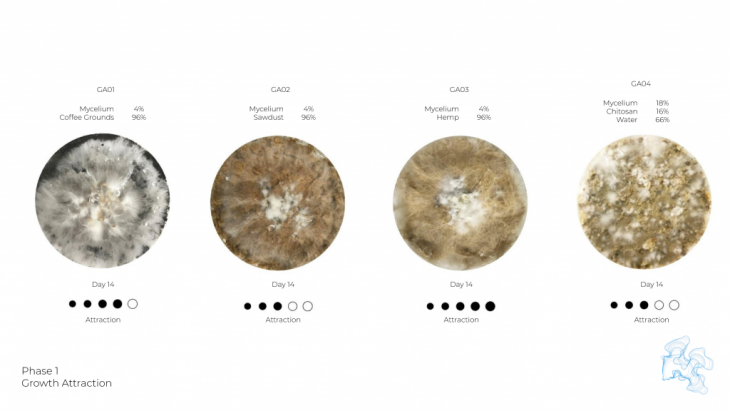

In order to accelerate the growth of the mycelium within the clay, we first tested a variety of nutrients such as Coffee Ground, Hemp, Sawdust, and more, in order to understand there reaction with mycelium.

Substrate tested the ability to combine nutrients into one composite and to examine whether this aided in the growth of mycelium.

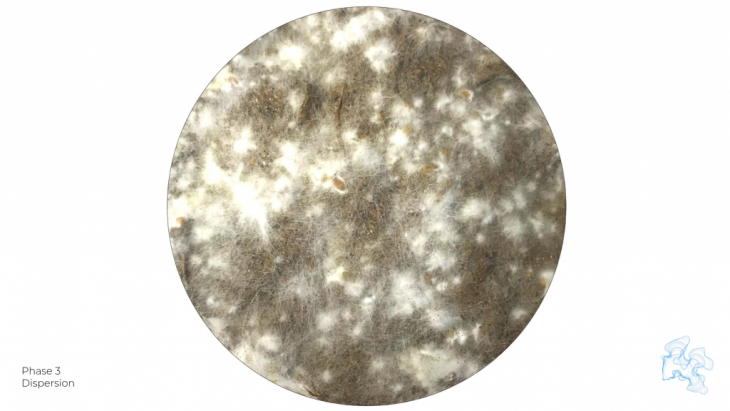

The dispersion experiments were done to test the ability of mycelium to be able to spread throughout clay. The concept of combining the nutrients with the dry clay was done to create pockets of nutrition for the mycelium to be drawn towards.

Due to our construction methodology of additive manufacturing we needed to test the feasibility of extrusion with the different composite and their ability to grow mycelium.

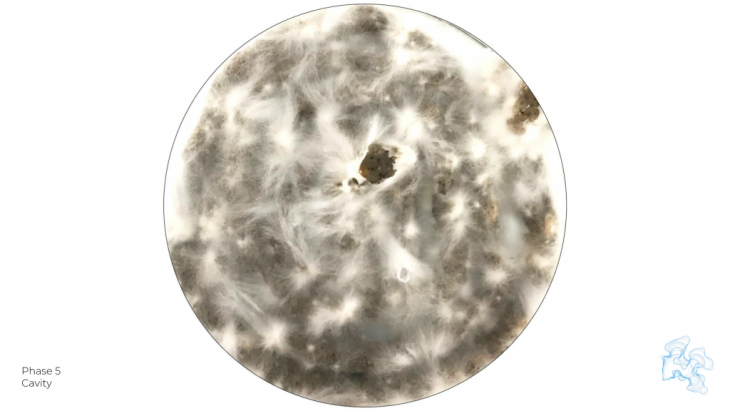

Cavity was an early concept to determine whether clay should be combined with mycelium during the process of material preparation or to fill the cavities with the nutrient based mycelium composite. These test varied in reference to growth of mycelium however, they were all consistent with the dramatic shrinkage that occurred after the incubation period.

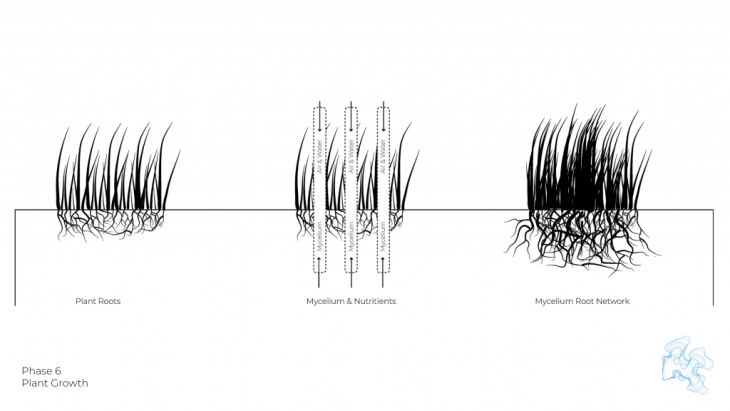

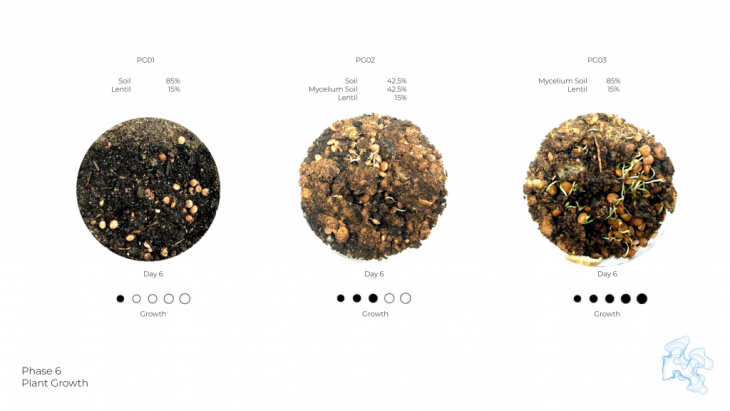

What you see here are three samples that have different soil mixes. The first is traditional store bought soil and the last is our my-soil. A combination of our optimal nutrients mixed with mycelium. The middle experiment is a combination of the the ones on each end.

We were also able to grow mushrooms both with our nutrient composite and claycelium.

From the conclusion in our 5 phases of experiments and the requirements we set for ourselves, we began to develop claycelium with Coffee grounds and sawdust acting as the nutrients and the clay and mycelium acting as structure. These nutrients we collected locally at no cost.

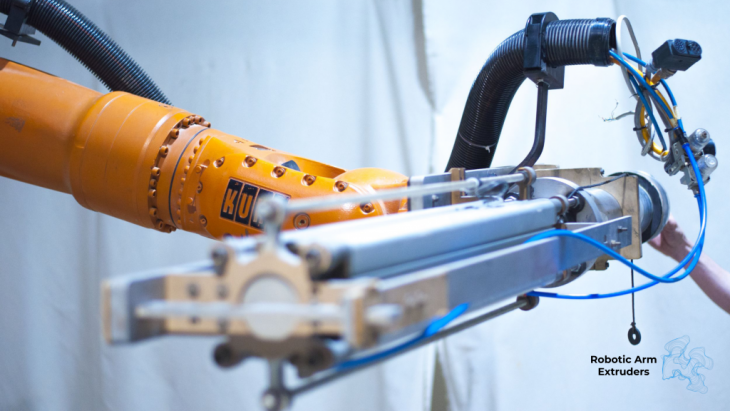

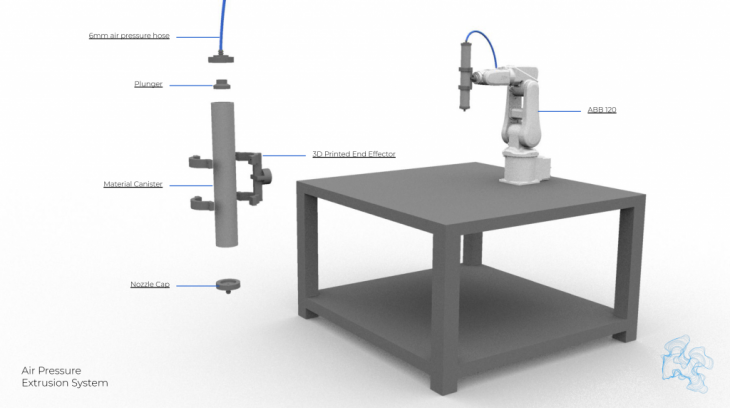

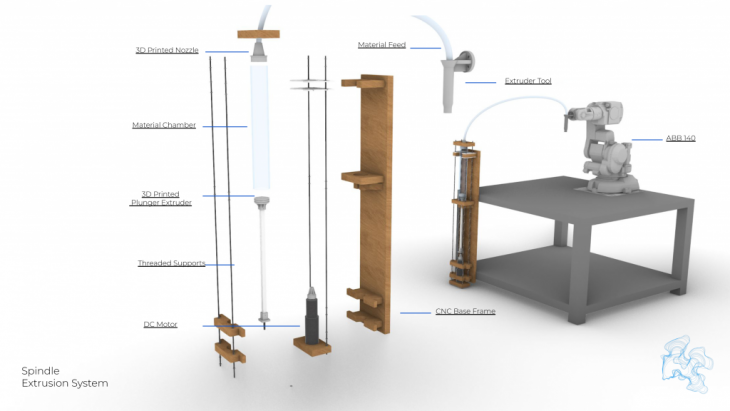

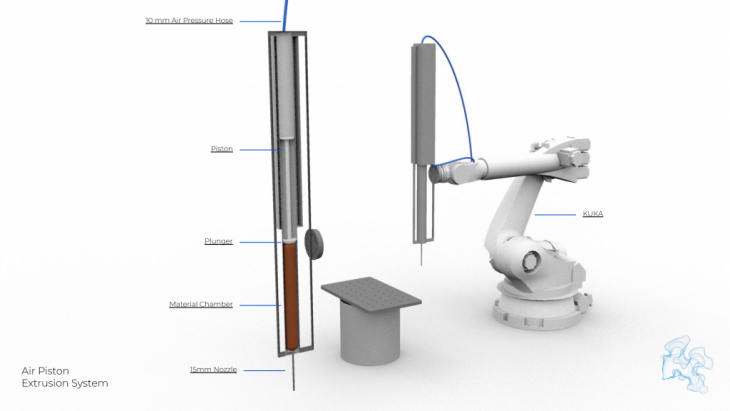

After our composite for Claycelium was chosen we then began to investigate its use in Robotic Construction. We used 3 versions of paste deposition modeling extruders in our research.

The first is an air compressor extruder, where material was placed in a cylinder and a plunger is pushed, with air pressure until, from one end and material will extrude out the other. In the beginning this extruder was not efficient due to the fact that a small pocket of air in the material will cause the extruder to create an burst of air that causes the destruction of the part.

In many ways this spindle extruder is the same as the air compressor extruder however, instead of air pushing material, we used a threaded rod attached to a motor which moved a plunger into material to be extruded.

The final extruder used was for large scale construction of our 1 to 1 prototypes. This piston extruder was nearly a combination of the previous two extruders. Air pressure caused a piston to extruder material out of one end. This system was very effective however, unlike the other two extruders, the viscosity of the material had to be precise there was no wiggle room.

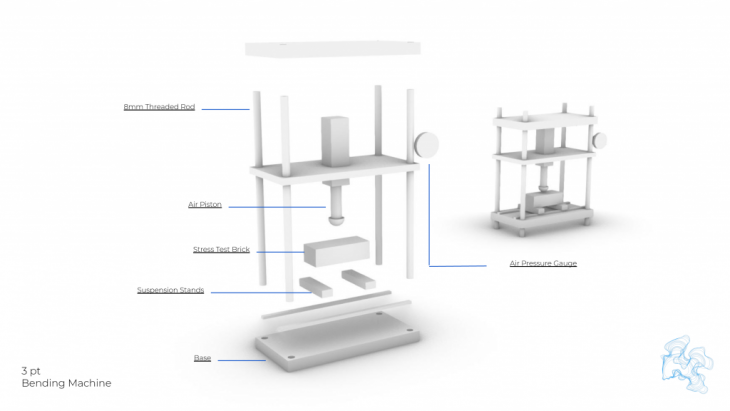

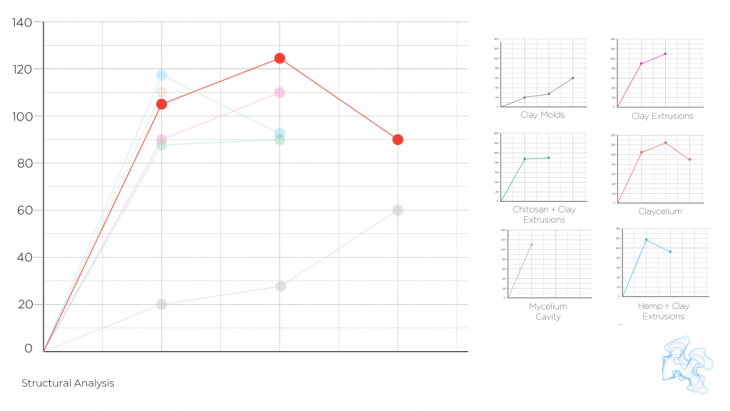

For the stress test we test the tensile strength of Claycelium and compared it to clay and clay with nutrient and no mycelium. These stress test bricks were constructed using the Spindle and Air pressure extruders.

The materials were tested using a 3 point bending machine. The stress test brick was suspended at its two ends and the piston would apply force to the middle part of the brick.

From these test we were able to conclude that Claycelium is 19% stronger in tensile strength than clay. These results were compared against a variety of tests and each test was performed multiple times.

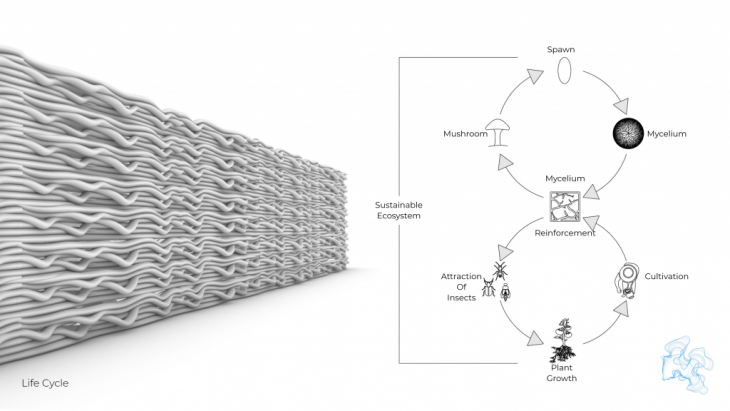

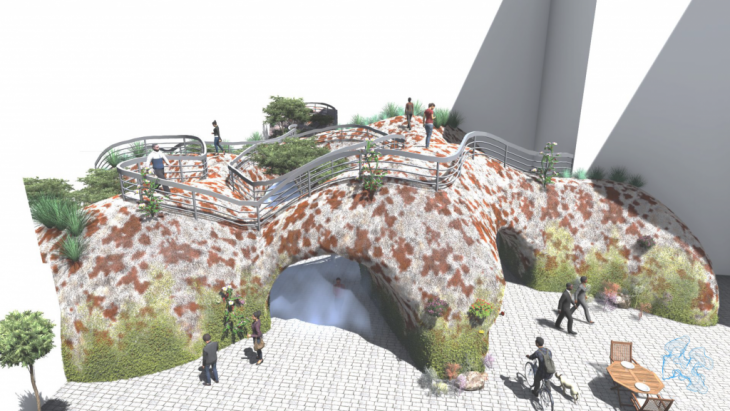

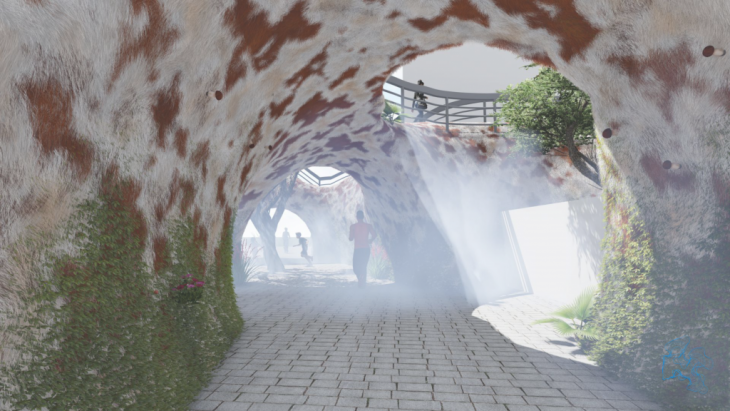

After the conclusions from the stress tests we began to look more into the materials architectural capabilities and the life cycle that would form. The architectural application designed for claycelium is an urban agricultural pavilion. The mycelium, within the pavilion, acts as a interconnecting network, that transfers nutrients between the mycelium and plant life while simultaneously reinforcing clay. This system creates a sustainable ecosystem.

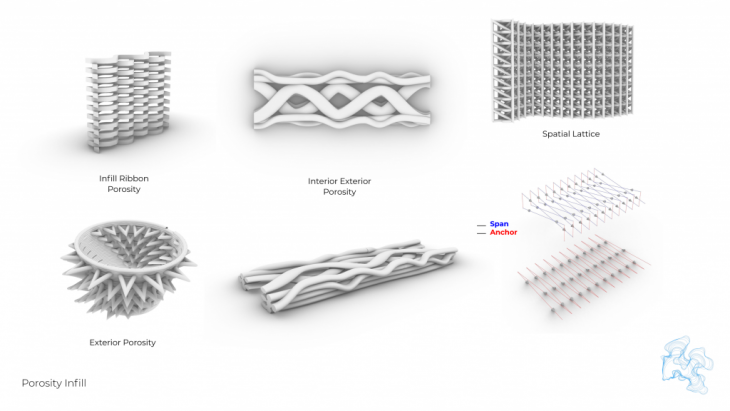

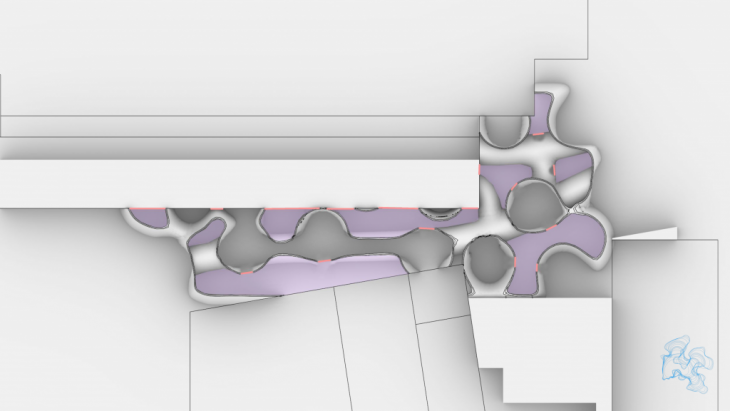

In order for mycelium to grow we need to allow oxygen to flow. In this phase we began to investigate the different opportunities for porosity.

In order for mycelium to grow we need to allow oxygen to flow. In this phase we began to investigate the different opportunities for porosity.

With our current robotic construction tools at IAAC we have to keep in mind that anything we create needs to be a continuous path. The porosity infills we explored were spatial lattice, an alternating ribbon and an idea of an exterior porosity that would not require an infill. All of these allowed for mycelium growth however, the spatial lattice required an AI construction machine. This is to say that as gravity affected the construction the robot would need to monitor the deviation and alter itself accordingly. With this in mind we focused on the exterior and ribbon porosity infills.

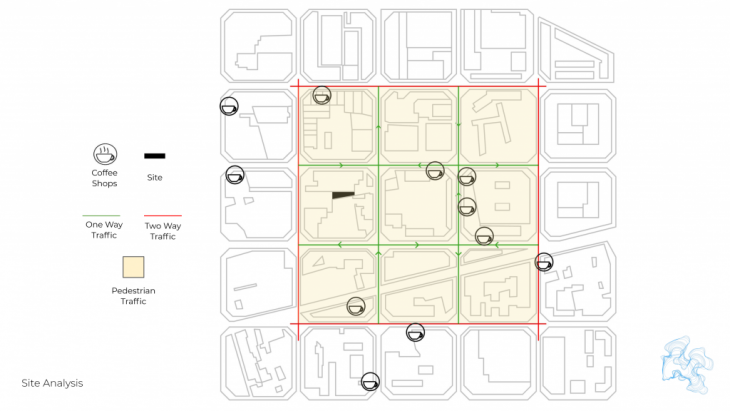

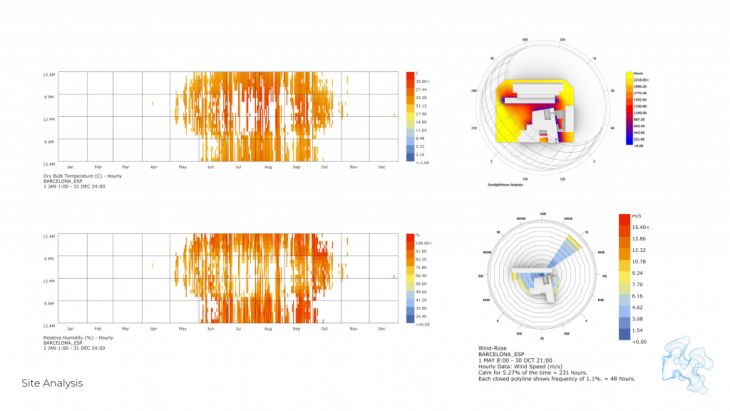

Taking into account our experimental parameters of temperature, humidity and light exposure we located a site that would fit the criteria within Barcelona and was is an area that would benefit from an agricultural production. The site we picked is located in Barcelona’s superblock, just down the street from where we are now.

The site was then analyzed for temperature, humidity, light, and wind exposure. From this we located a time in which the natural environmental conditions were ideal for mycelium growth.

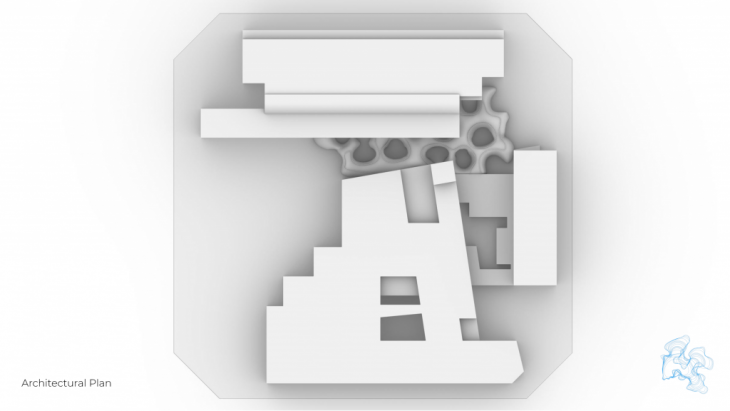

This algorithmic generation created a form that was not only perfect for mycelium growth but was also prime for agricultural production.

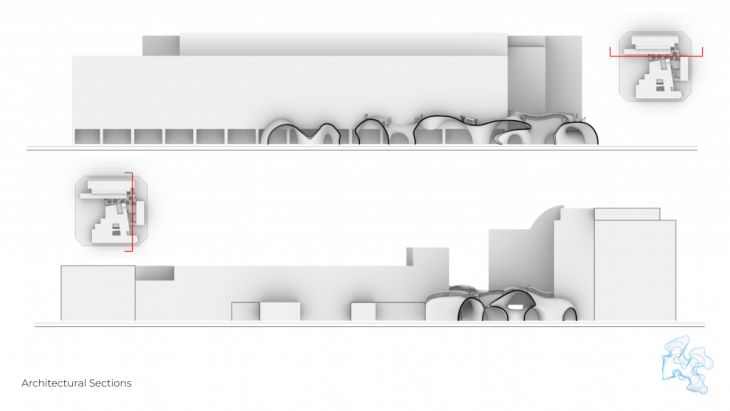

As seen in these sections the design became an organic pavilion that flows through the designated site.

Future Applications

AR Agricultural Cultivation

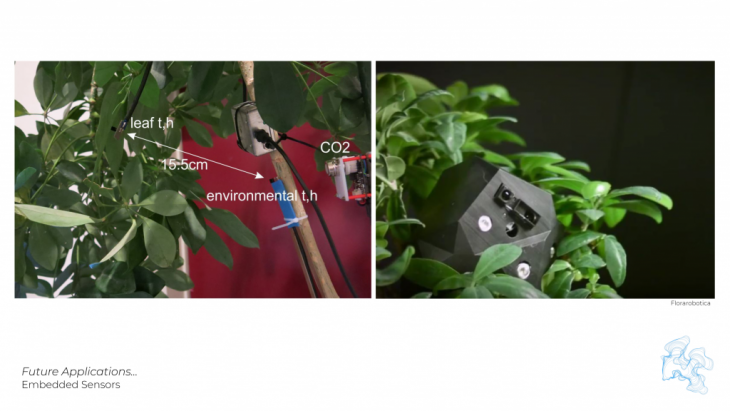

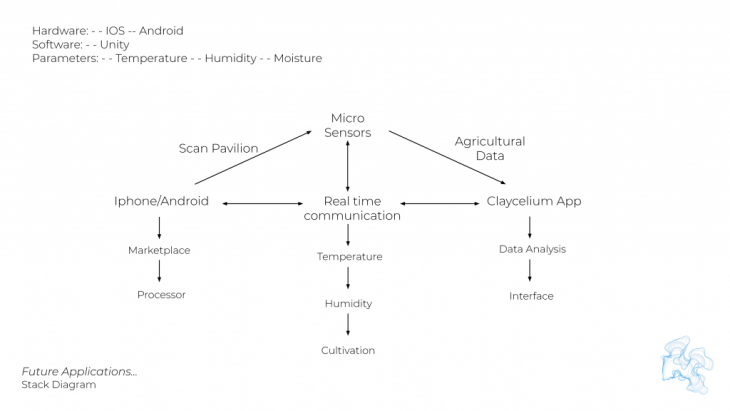

As an idea of future applications to be implemented we have come up with an interactive AR app that allows the community to not only cultivate there of produce but also monitor it. This is done through embedded sensors.

As a precedent for these embedded sensors we took a look at Florarobotica that used sensors as a way to naturally grow architecture.

The cycle for this app would allow the user to grab their phone, Apple or android, and open the Claycelium app. Then the phones camera is directed to the pavilion and the data from the sensors are collected real time and displayed within the app.

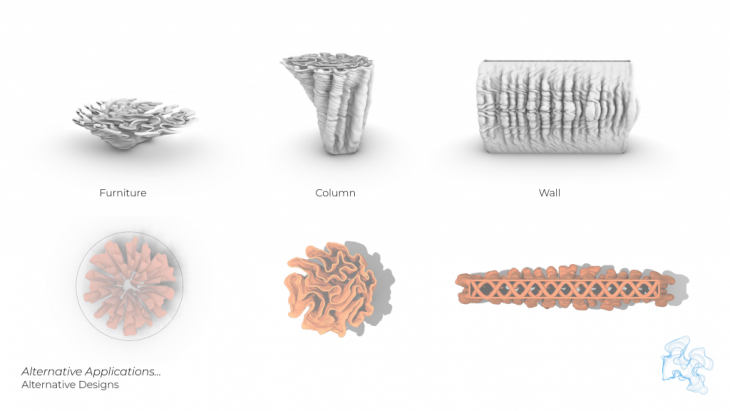

Claycelium is not limited to just Architectural Structures.

Claycelium can be used for furniture, walls columns and more, that will all produce agriculture for the community.

Developed in:

Digital Matter, IAAC, 2019

Project by :

Justin Sheinberg & Mert Gönül

Faculty:

Areti Markopoulou, David Leon, Raimund Krenmueller

Student Assistant:

Nikol Kirova