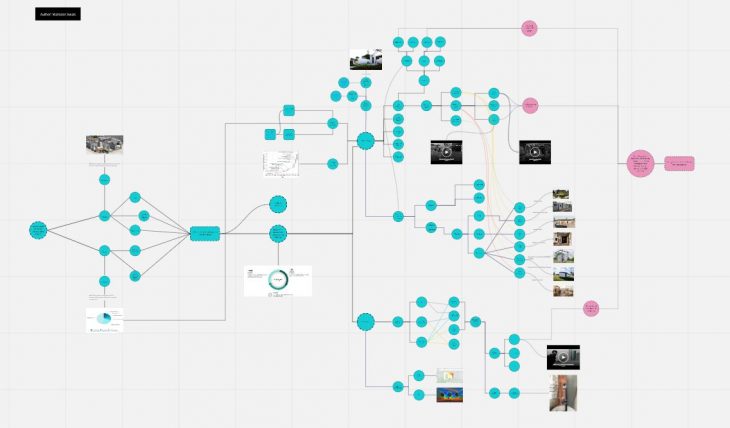

Overview

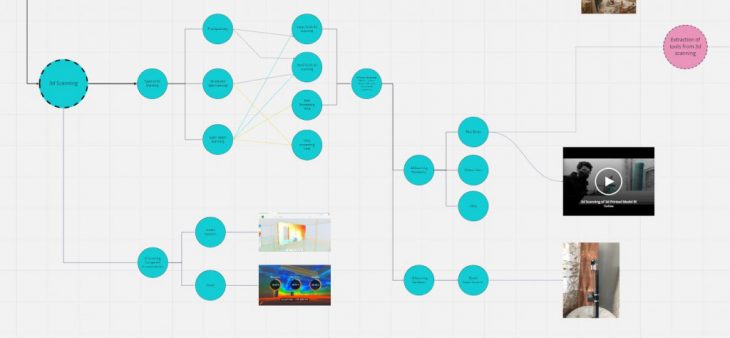

An exercise of the workshop is to summarize overall research in a big diagram. Diagram tells about the aspects of research which contribute to the choices and impact. There are 3 tracks in the research year of MRAC 02. Out of which I’m working on the industry track. My topic is Cyber physical 3d printing so I have explained about the process and the background to the reason of choosing the topic. The diagram is read from left to right.

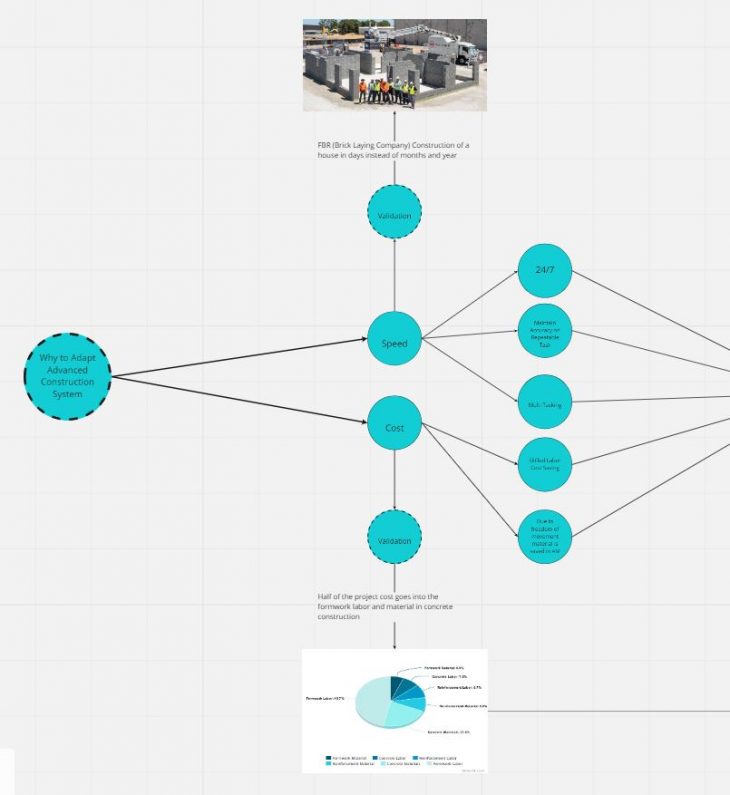

Why Advance Construction System

There are many reason to apt for Advance Construction techniques but the major I have taken are the speed and Cost of the project. Validation for the speed of the project is from FBR Brick laying company which can built the house in days and weeks instead of years. Where as the Cost of the project validated by the estimation of the material saved through additive 3d printed construction.

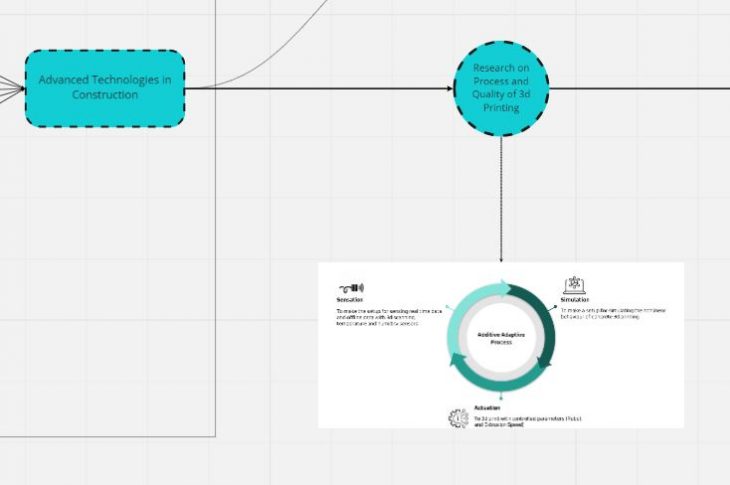

Research Objectives

There are 3 research objectives which are in a cycle are supposed to improve with each other over time. The three objectives are Actuation, Sensation and Simulation. Actuation covers the 3d printing process, Sensation covers the 3d scanning of the 3d printed parts and capturing of other data points, Simulation is about to analyze predict the possible issues in 3d printing in advance though the data gained by sensation process.

Trends and Policies

This parts explains the policies which are impacting the construction industry and validation of 3d printing on architectural scale. Dubai government announcement for the 3d printed construction of 25% buildings by 2030 has opened new opportunities for advancement in construction. And also the graph shows the number of project comping to reality with 3d printing are increasing each year.

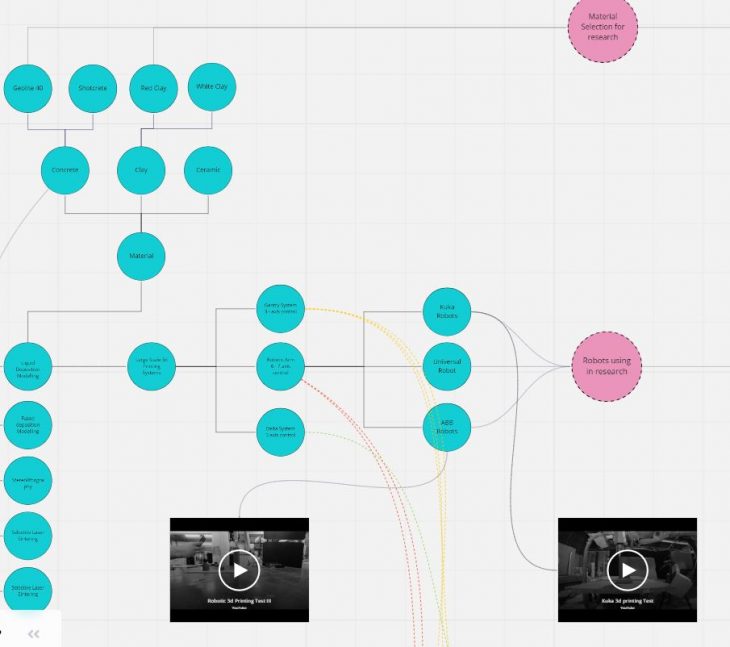

Existing Technologies in 3d printing

So there are different process in 3d printing and the one which is far most applicable in large scale construction is the LDM process. The material I am working with is the clay and concrete. The robots I’m using for my research are ABB, Kuka and UR. All of the 3 are selected on the basis of printing size and interactivity. Attached are also the tests I have performed so far.

1d & 3d Scanning for Quality Check

In this part there is an explanation of the existing types of scanning technologies and the companies which are already doing 3d scanning on construction sites which is the validation of this technology in construction. And also are the attached test of 1d and 3d scanning tests for assessing the quality of 3d printed models.

Simulation

In this part of the research all the data gathered is used then for the prediction models. 3d printing on construction site is not as controlled as in the manufacturing units. So by utilizing the data can improve the system performance for on-site construction.

Built 3d (Cosmogramme Workshop) is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at the MRAC-02 program in 2020/21 by:

Research Student: Mansoor Awais

Tutor: Mireia Luzarraga