Bio – Fabric

Our studio aims at developing a production line that uses microorganisms to create a biomaterial. Cellulose is an insoluble substance which is the main constituent of plant cell walls and vegetable fibers, it is also used for producing paper. Microbial cellulose is a form of cellulose produced by bacteria, characterized by high purity, strength, moldability and increased water-holding ability. Microbial cellulose can be produced from sugars in organic waste and takes a period of 2 weeks for growth.

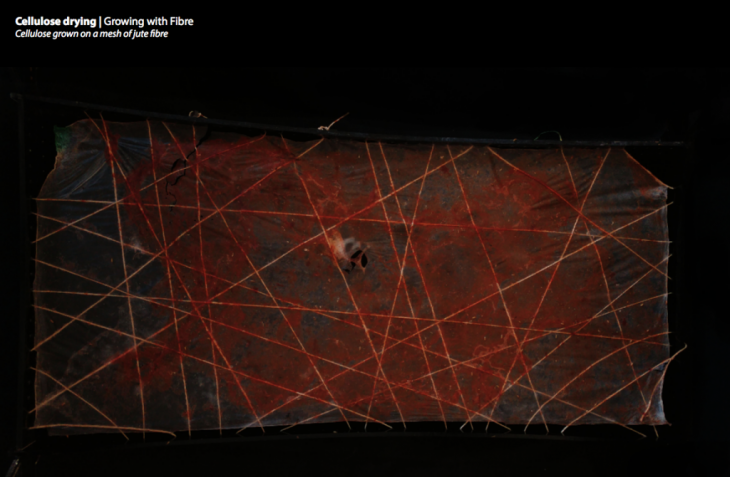

Our thesis aims at producing microbial cellulose from the organic waste generated in the city. The cellulose, when dried, becomes a material which can be molded to precise geometry and can be grown from a variety of organic raw materials and pigments. Further, the cellulose is grown on a mesh created with natural fibers such as jute which further reinforces it. The experiment would demonstrate how organic material can be reproduced and made bespoke. After collection of raw materials, we propose to grow the material in a public area involving the community in the process of production.The process is made transparent and interactive to help build a relationship with the material and the city.

Barcelona is one of the most dynamic cities in the world and it is constantly adapting to the population needs and practices. This change brings a new set of challenges. One of these being waste management for the growing population. Our project aims at a different outlook towards conventional material by developing new materials using the waste from the city as an input and bringing the community together to create a new Anthropocene landscape.

Microbial Cellulose

Microbial cellulose, sometimes called bacterial cellulose, is a form of cellulose that is produced by bacteria. The cellulose exhibits good mechanical strength and high water absorption capacity.

Acetobacter Xynilium is the most common bacteria that forms microbial cellulose.

Observation of Microbial Cellulose In 4 stages.

The standard preparation of the cellulose:

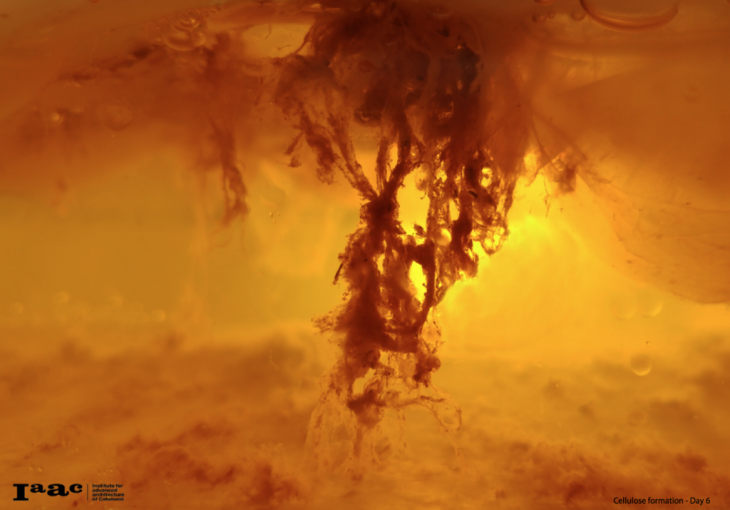

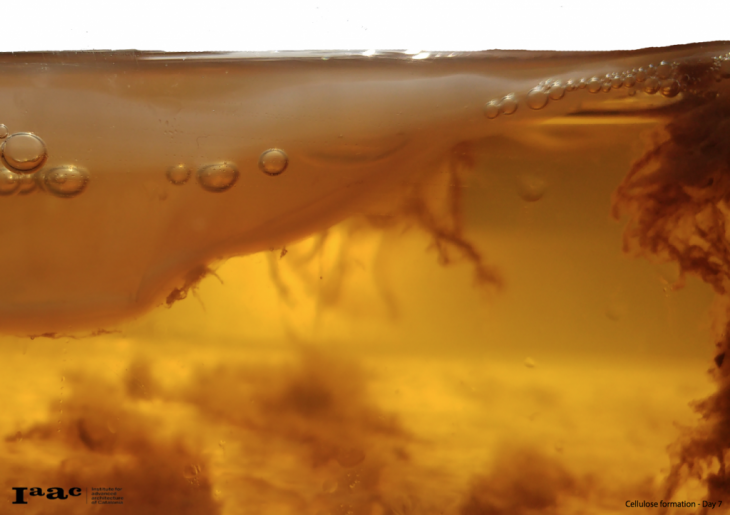

Cellulose formation – 6 days:

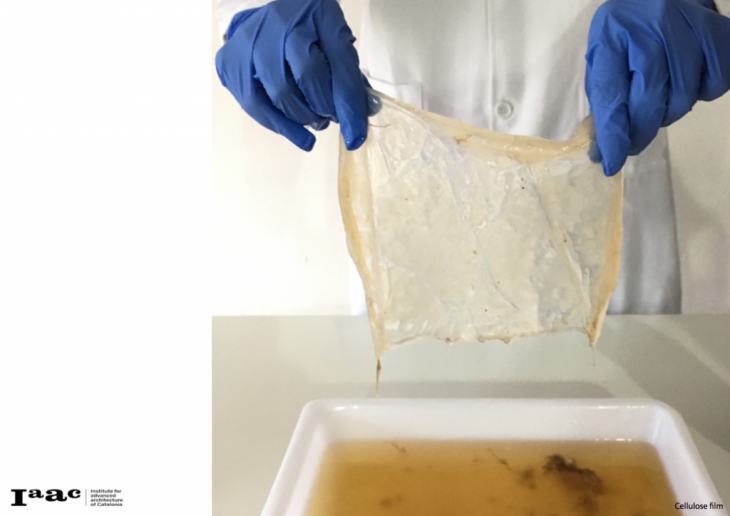

Cellulose film:

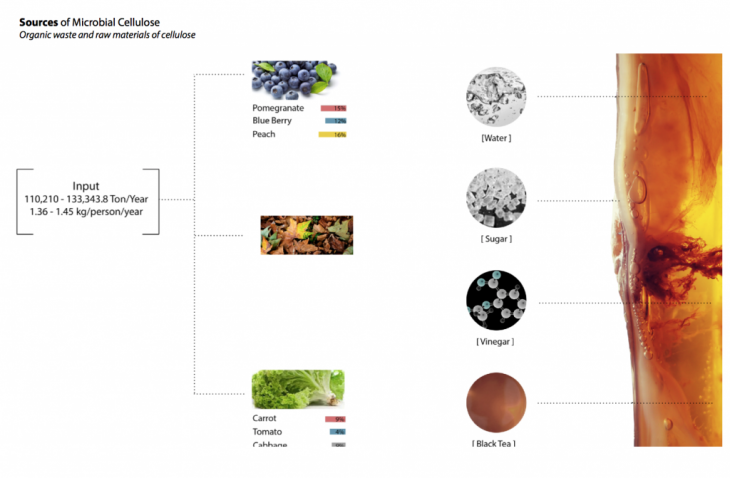

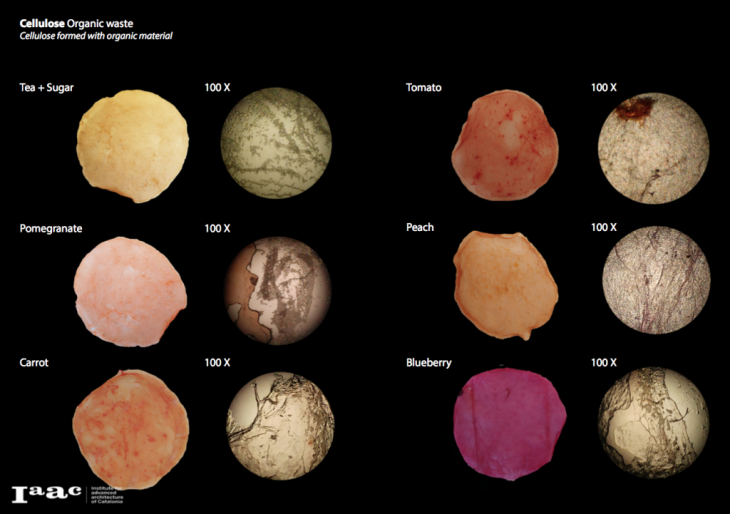

For this part of the research, we analyzed the production of the cellulose in relation to the organic waste generated around Barcelona. Why? Because in the basic formula, the sugar can be replaced with the sugar found in vegetables and fruits.

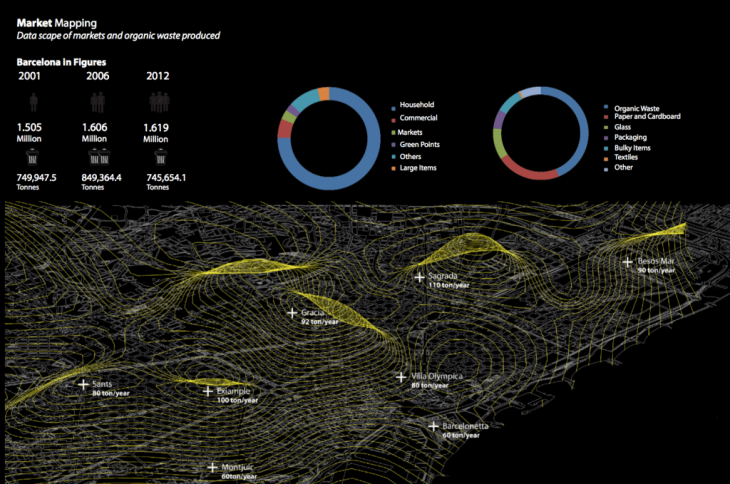

The study concluded that more than 40% of the total waste generated in the city is the organic waste.

Households are the main source of organic waste followed by markets, for easy segregation and collection we concentrated markets as the source and mapped the amount of organic waste produced in different parts of the city.

Preparation from organic waste, using tomato as a substratum.

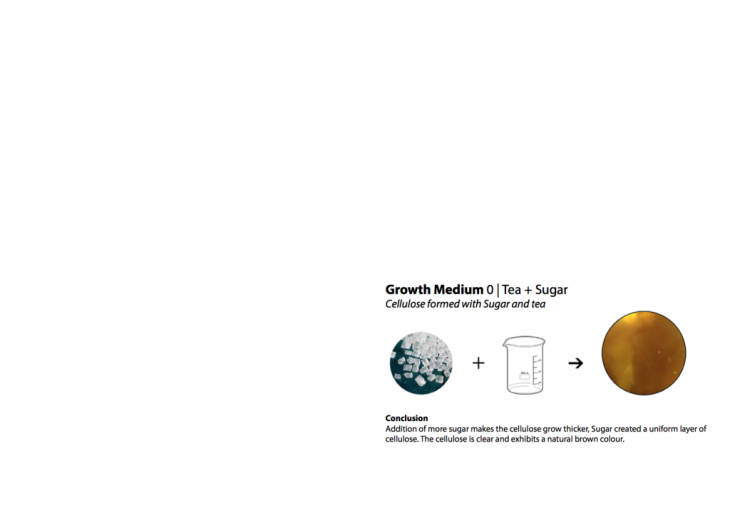

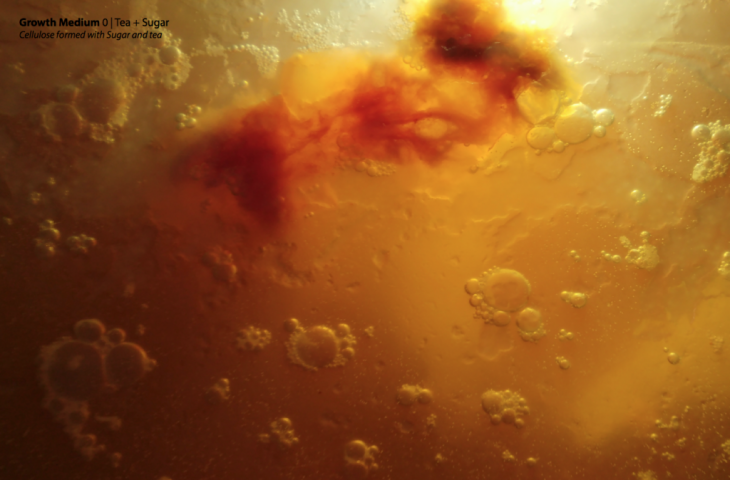

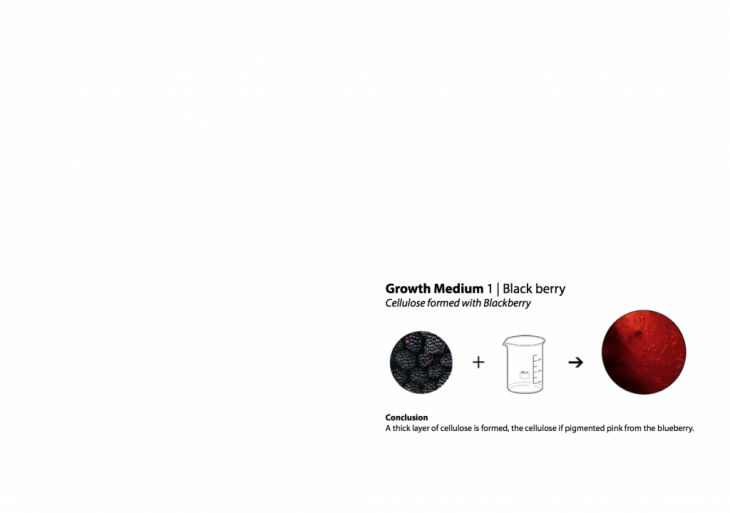

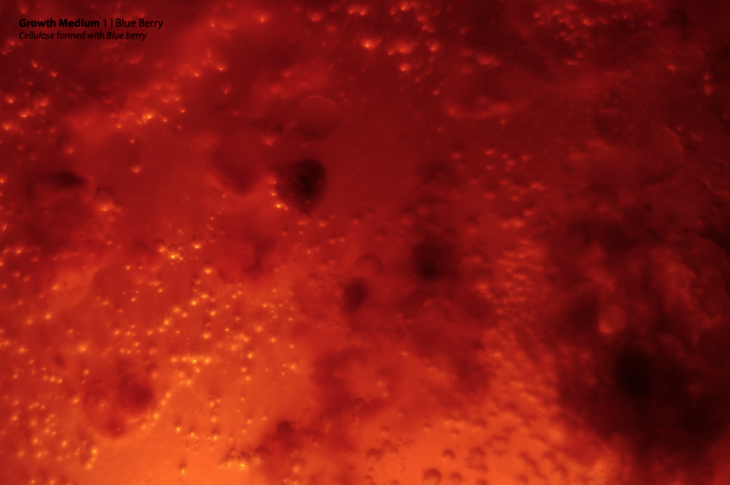

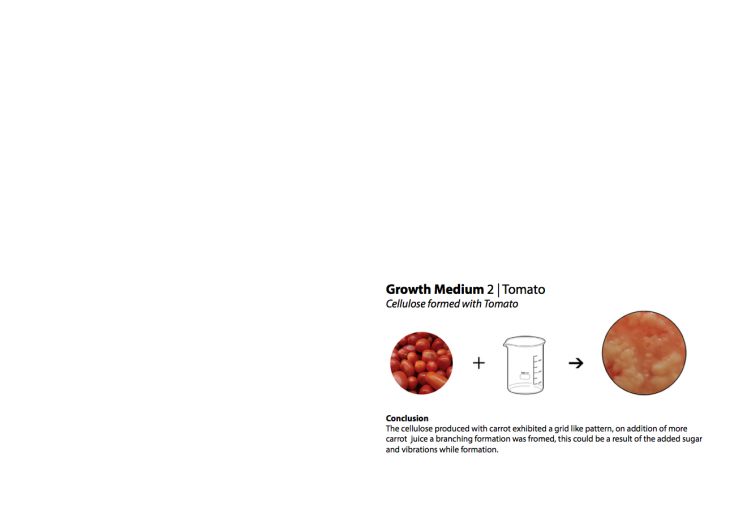

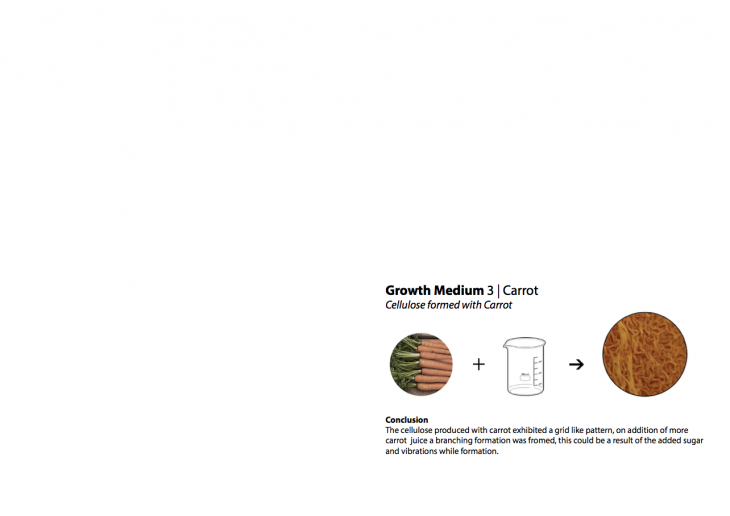

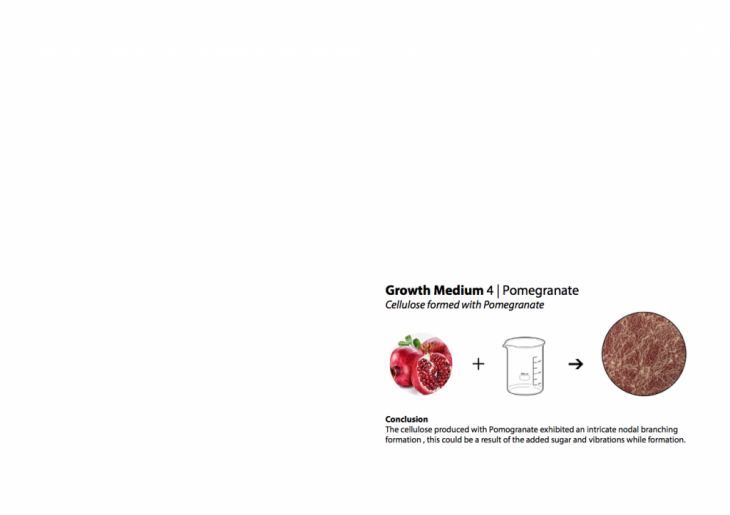

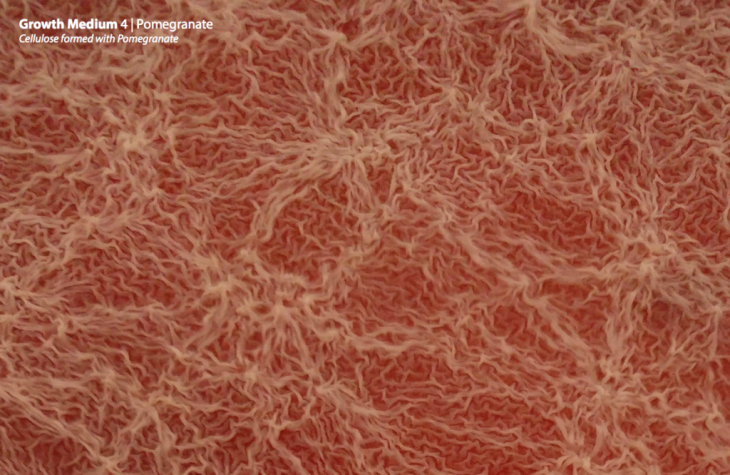

The growth of cellulose in different mediums.

Experiments were conducted growing the cellulose using different fruits and vegetables as the source of sugar. The properties of the resultant cellulose were analyzed.

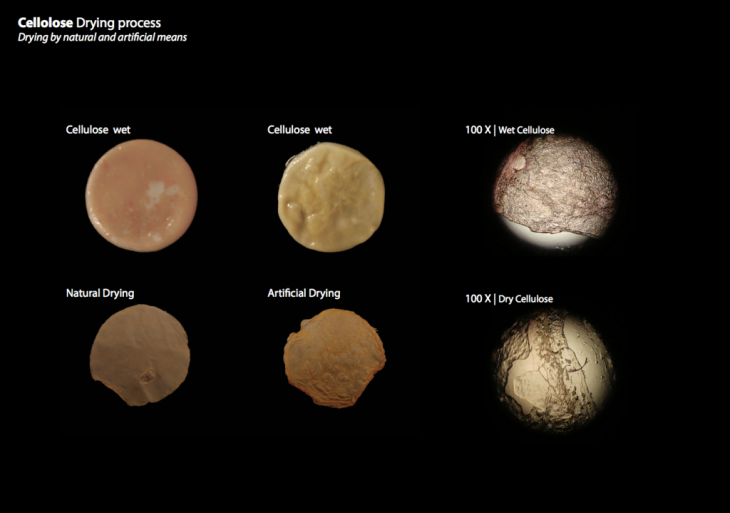

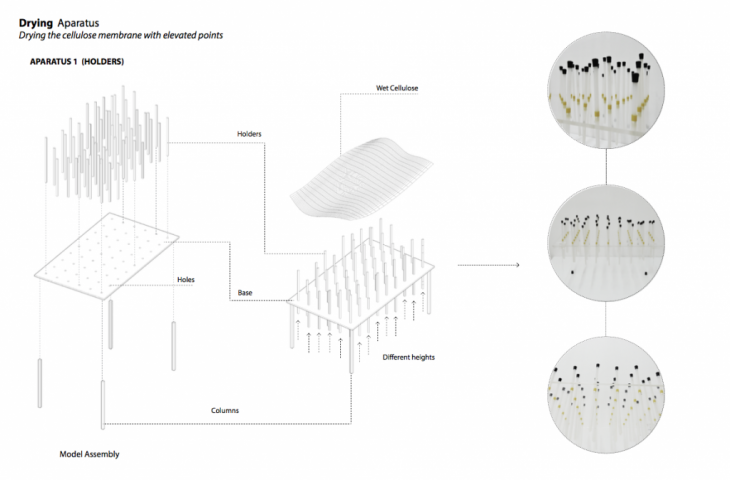

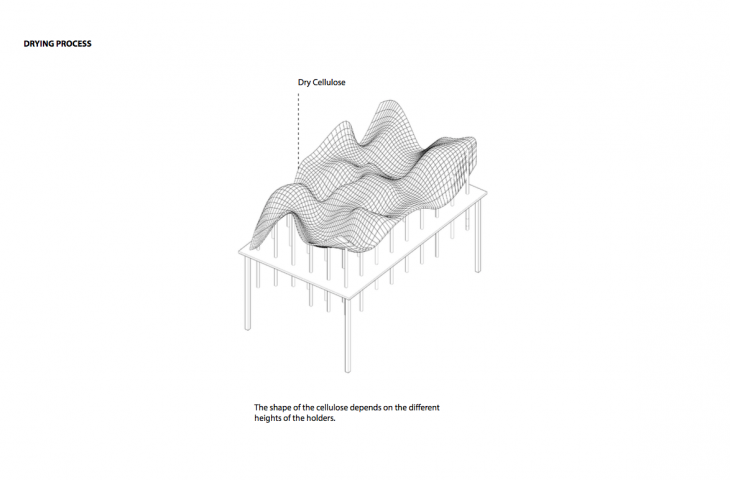

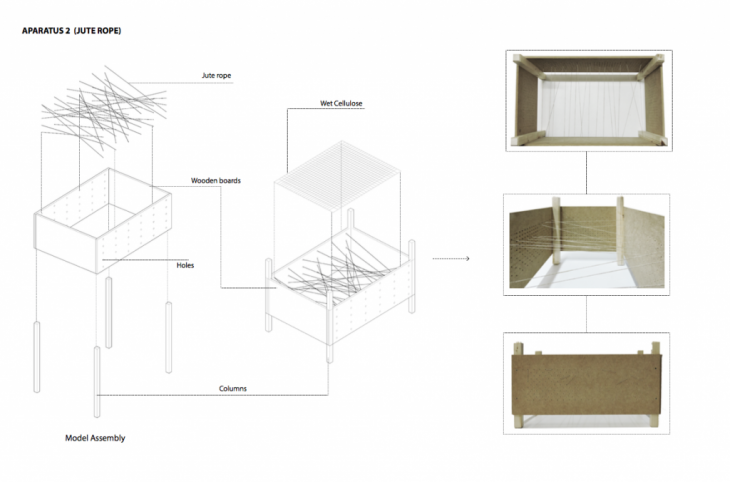

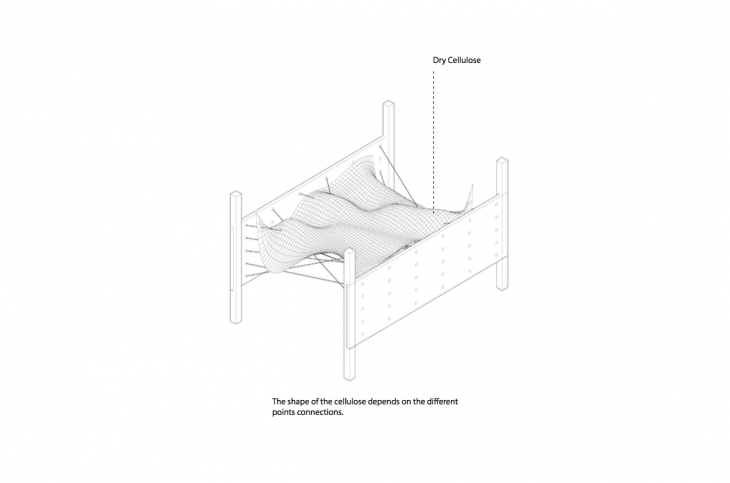

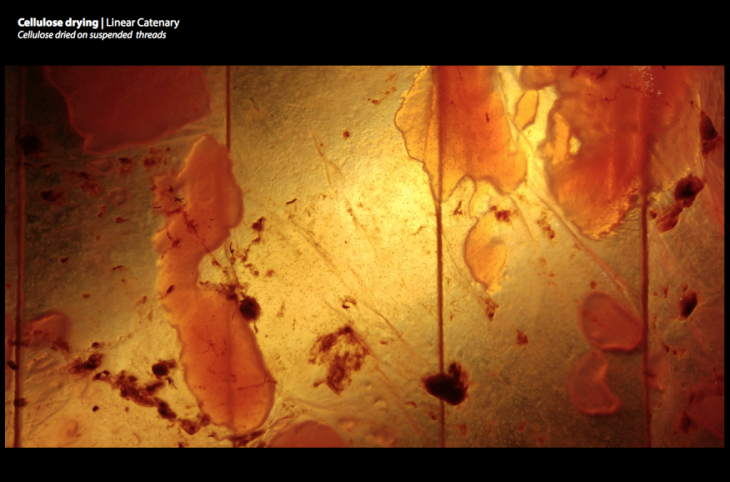

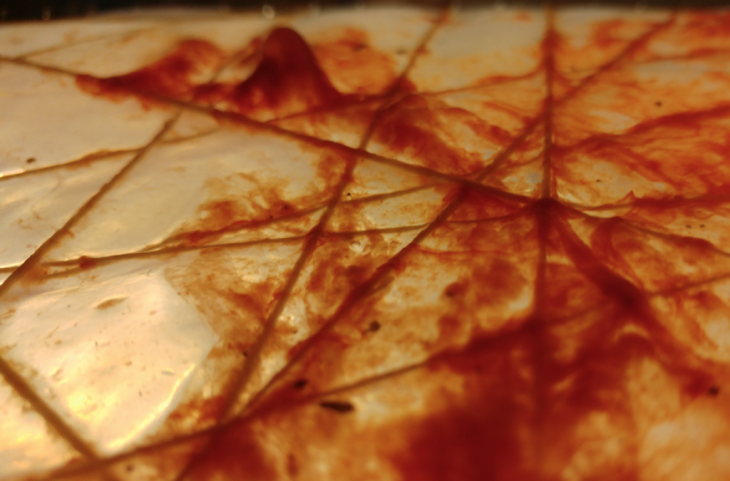

After all the growing stage we started studying the drying process of the material. We understood that the cellulose has a contraction capacity when is drying, so we took advantage of that and design many apparatus to control many kinds of shapes.

Apparatus for drying the cellulose:

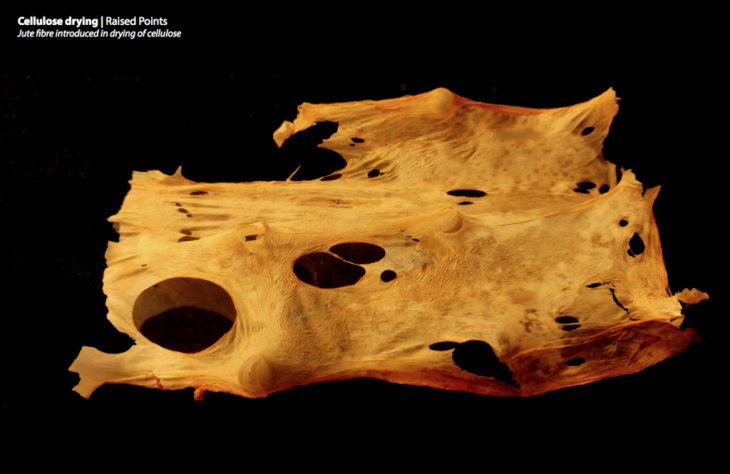

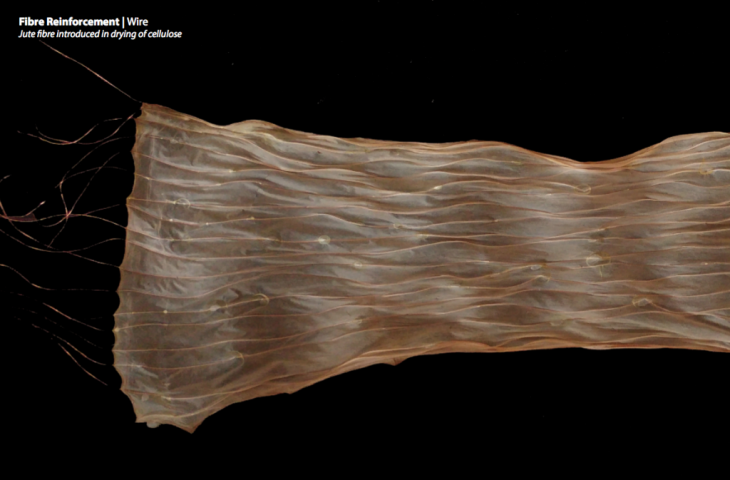

Fiber reinforcement:

After drying just the thin layer of cellulose we realized that we should give more strength to the material by introducing fibers at the end of the growing process. The outcome was a reinforced organic fabric.

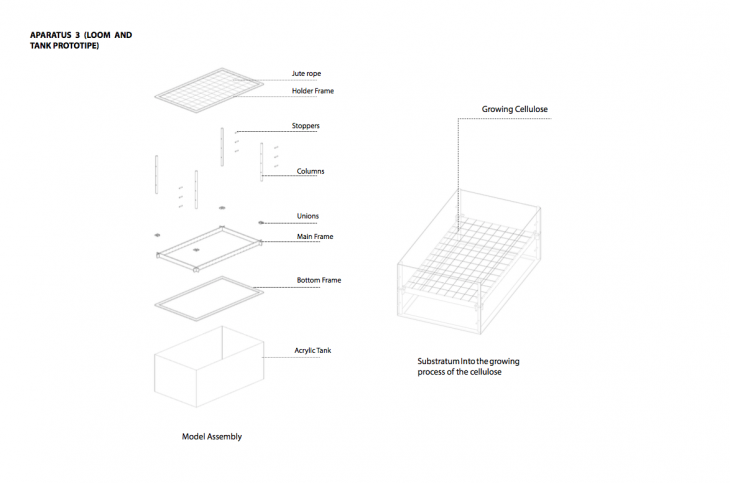

apparatus prototype 3:

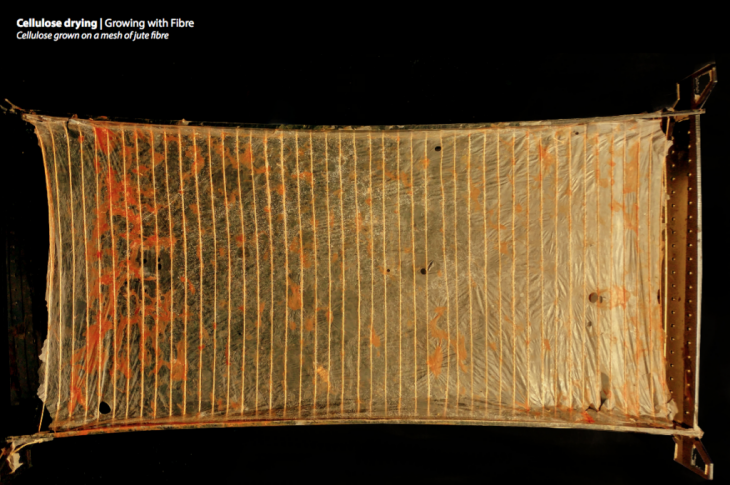

We combined the fibers and the membrane in the growing process of the cellulose. – The cellulose attaches to the fibers while growing.

The apparatus creates a continuous membrane which is reinforced with a mesh of fiber, the pattern of this mesh can be changed according to need.

At this point we have a membrane of cellulose with a mesh inside. So we can take advantage of all the nodes in the mesh and can control the final shape of the fabric.

The cellulose can be used for various purposes and made bespoke. The cellulose formed can be formed to precise geometry and exhibits mouldability. We have made a demonstration of how the cellulose could be used in a public square for engagements, the cellulose provides shelter and shade, it is temporary and can be degraded after use.

The creation of cellulose helps the city manage its organic waste. By making the growing process transparent and interactive, a relationship is built between the material and the city.

Students:

- Cesar Arroyo

- Sandesh Kagganti

- Nikita John

- Sujal K Suresh

- Quan Li

- Claudia Pasquero (Introductory Studio Tutor)

- Carmelo Zappulla (Introductory Studio Tutor)

- Maria Kupstova (Introductory Studio Assistant)

References –

http://etheses.bham.ac.uk/5980/1/Chen15MRes.pdf

http://www.stschwabe.com/work/XylinumCones/

http://cargocollective.com/najarydeankarfeldt/microbial-machine

https://www.omicsonline.org/open-access/bacterial-cellulose-production-and-its-industrial-applications-2155-9821.1000150.pdf