ARGYLE BEAM

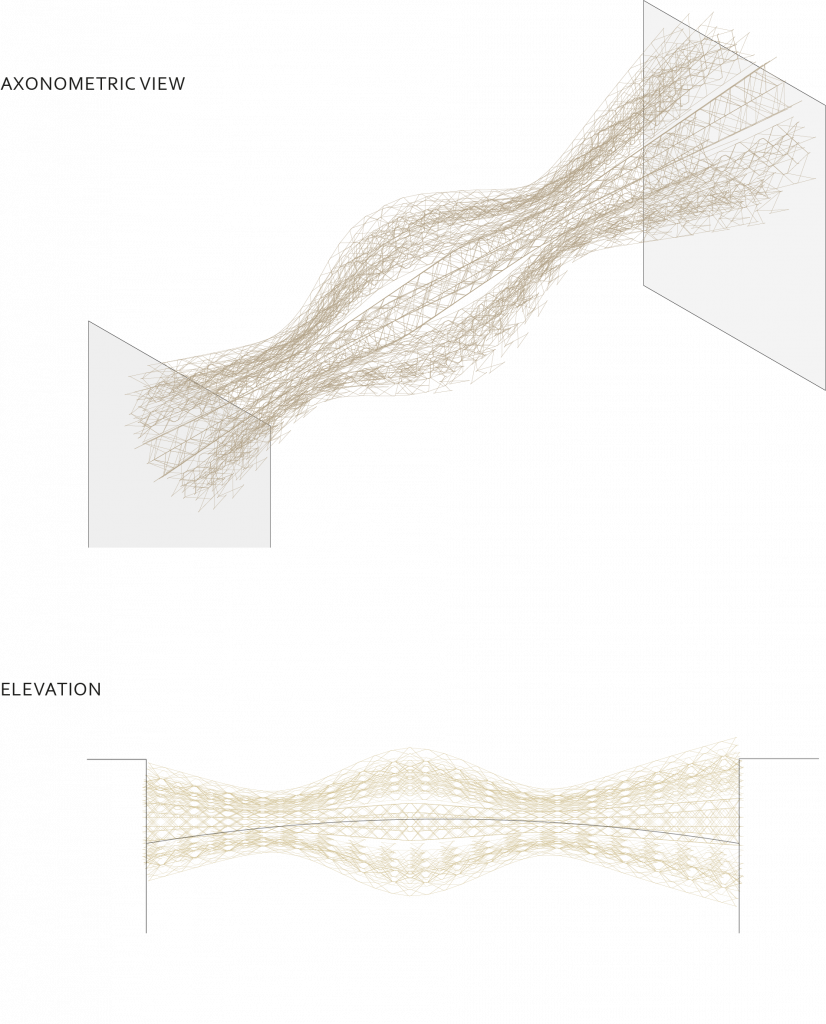

Argyle is a rebar beam that has fabricated by robotic arms. It consists of a single module that has been arrayed by defined parametric rules to form a beam. It has 4 main components that form a primitive module by combining. Later on, these modules are arrayed. The parametric rules for the array have been optimized for production. The number of beams, cross-section dimensions and the number of modules have been optimized in order to create a beam that has a minimal difference between its main components.

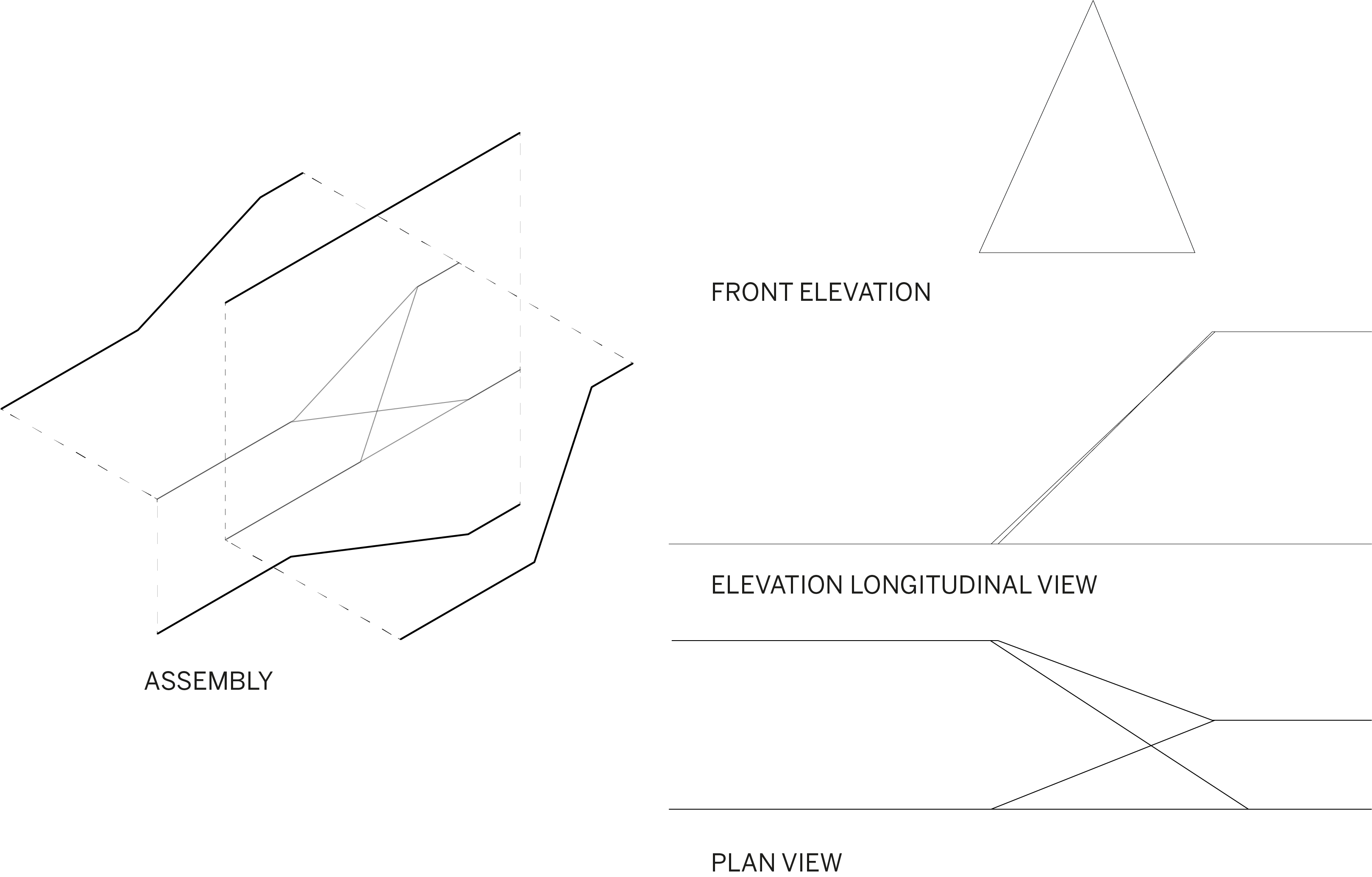

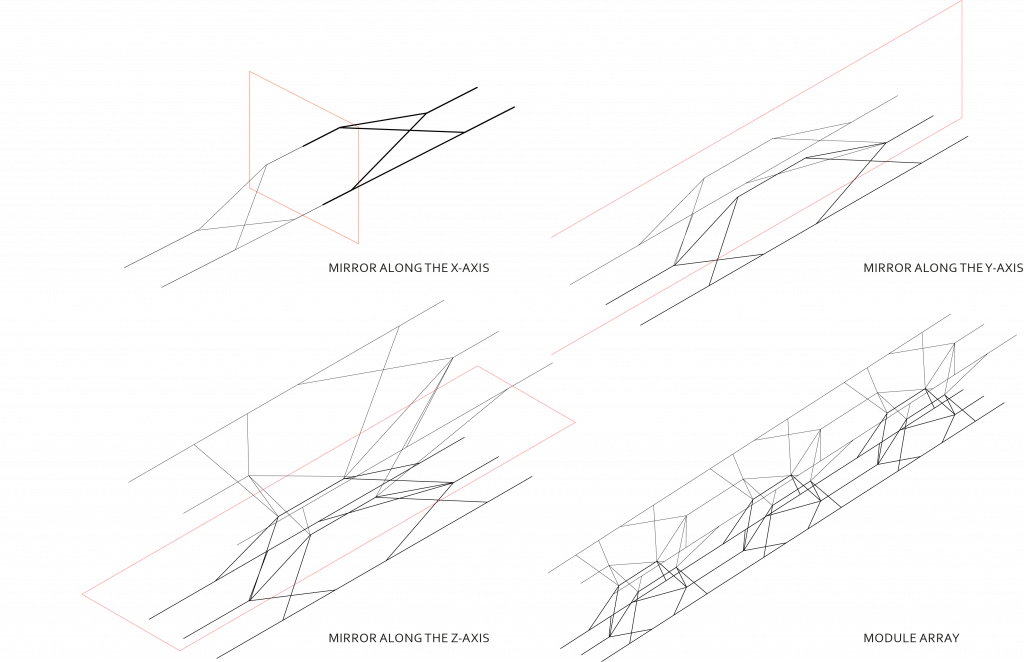

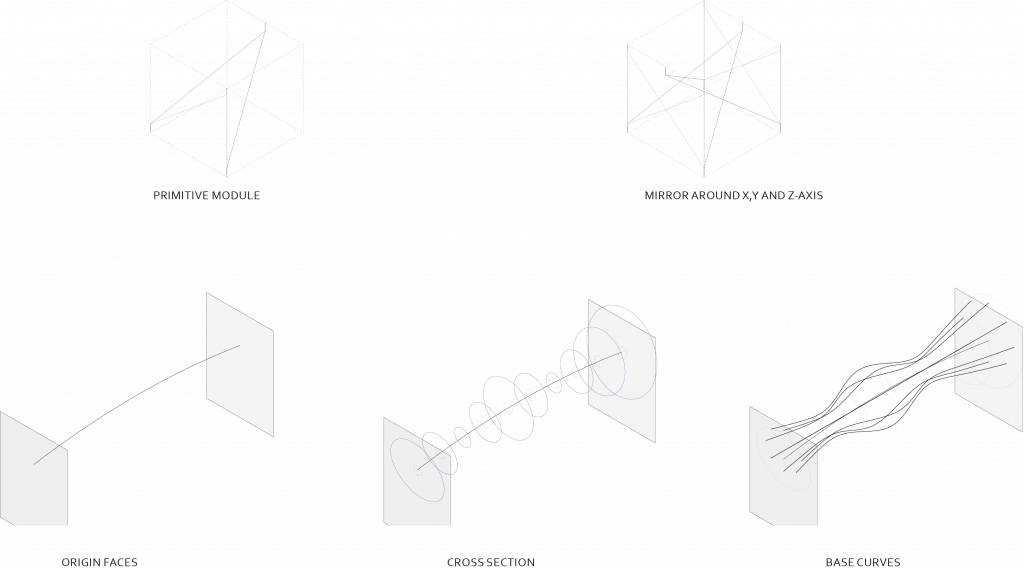

Primitive Module Design

Fabrication Methodology

Parametrized Design

Pseudo Code

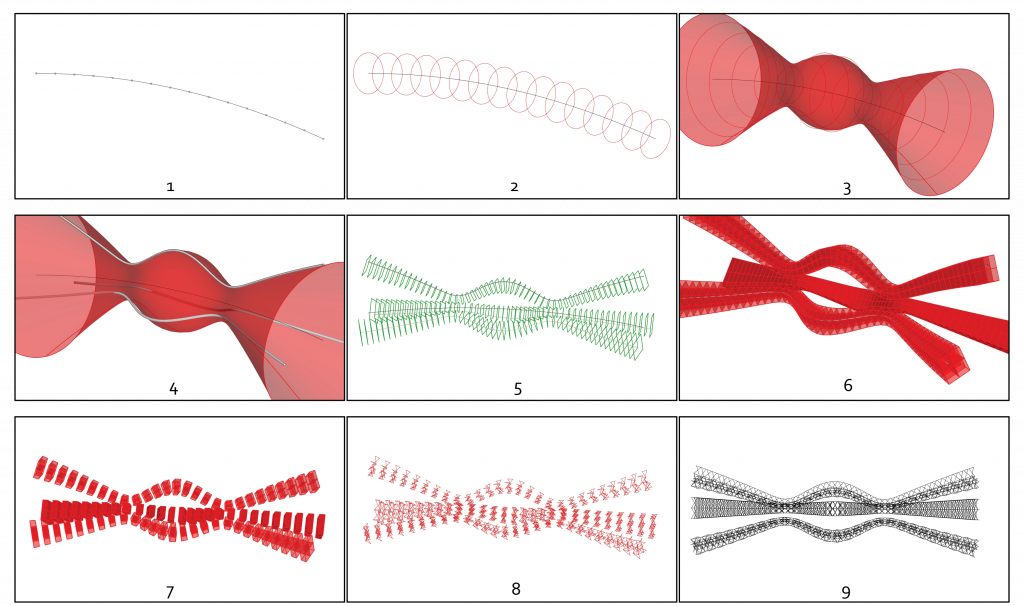

1. Create a base polyline for the bridge.

2. Divide the polyline 16 and place a circle into every division.

3. Add two attractor points and scale the circles in relation to the distance.

4. Project the base polyline to the lofted surface n times to form the base of the beam structures.

5. Divide projected polylines into perpendicular frames, and scale them according to the curvature of the lofted surface.

6. Create a twisted box through perpendicular frames.

7. Group every other twisted box.

8. Morph the primitive modules into twisted boxes.

9. Merge the two groups together.

Optimization

The number of the beams, number of modules, cross-section dimensions and the attractor factors are optimized to achieve the minimum length difference between components and rebar lengths that are closest to the dimensions that robotic arm can fabricate.

Argyle is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at the Advacned Robotic Fabrication, and optimized in Computational Design. Student: Doruk Y?ld?r?m Faculty: Rodrigo Aguirre Physical Computing Expert: Daniil Koshelyuk, Nikoleta Mougkasi