Anthropocentric Humanless Architecture is an automated system of production of which the urban layout is based on the machines and their needs. The concept behind the project is based on two philosophical movements: Object Oriented Ontology (OOO) and Hyperobjects.

Object Oriented Ontology (OOO)

Object-oriented ontology (OOO) is a 21st-century Heidegger-influenced school of thought that rejects the privileging of human existence over the existence of nonhuman objects. This is in contrast to what it calls the “anthropocentrism” of Kant’s Copernican Revolution, in which phenomenal objects are said to conform to the mind of the subject and, in turn, become products of human cognition. Graham Harman, 2002

Hyperobjects

Hyperobjects refer to things that are massively distributed in time and space relative to humans. They are denominated hyper in relation to some other entity, either manufactured by humans or not. An example of hyperobject is Global Warming, or the Solar System, or even the total sum of solid waste ever produced on Earth. Timothy Morton, 2013

The project aims to propose a new approach to Urban Design which is not human-centered anymore, but machine-centered, by taking an existing phenomena/hyperobject – automation in mass production – and accelerating it in order to propose a feasible future scenario based on nowadays reality.

PROJECT AREA

Naples

– 3rd most populous city in Italy

– 9th most populous urban area in the European Union

– 3rd most populous European Metropolitan area in the Mediterranean Sea

Bagnoli

– West Side of Naples

– Former Industrial Area

– 300 acres

Naples is one of the most conservatives cities in Italy, it’s potential drawn by its position and its dimension is suffocated by the local mentality, representing the perfect scenario by creating a strong contrast between the project and the city itself.

CASE STUDIES

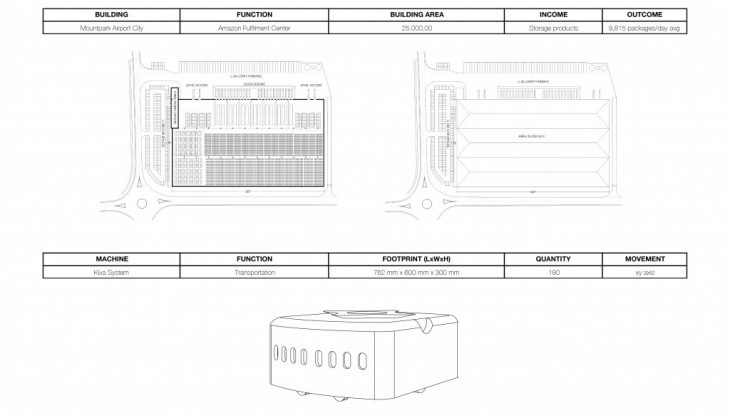

Mountpark Airport City – Amazon Fulfillment Center

Gigafactory – Lithium Ion Batteries and Tesla Cars production

Amager Bakke – Waste-to-Energy Plant

Shenzhen East – Waste-to-Energy Plant

Techno Farm – Indoor Lettuce production

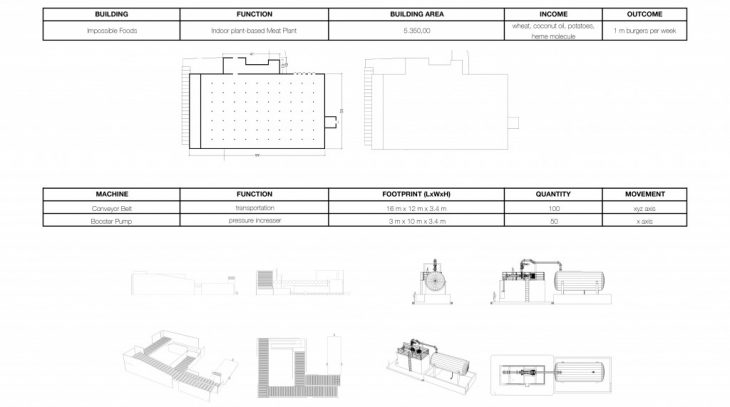

Impossible Foods – Alternative Meat production

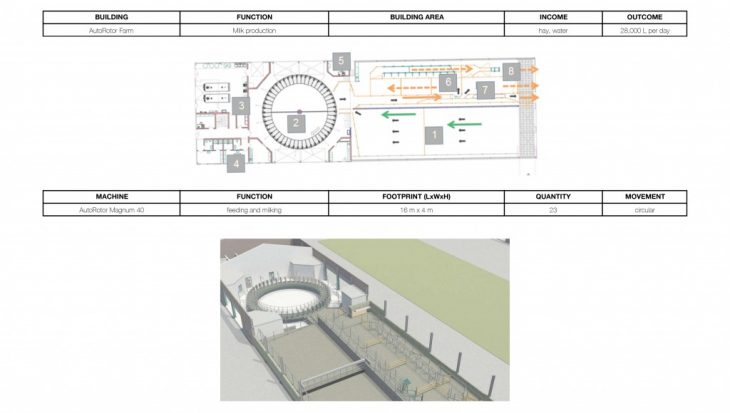

AutoRotor Farm – Diary production

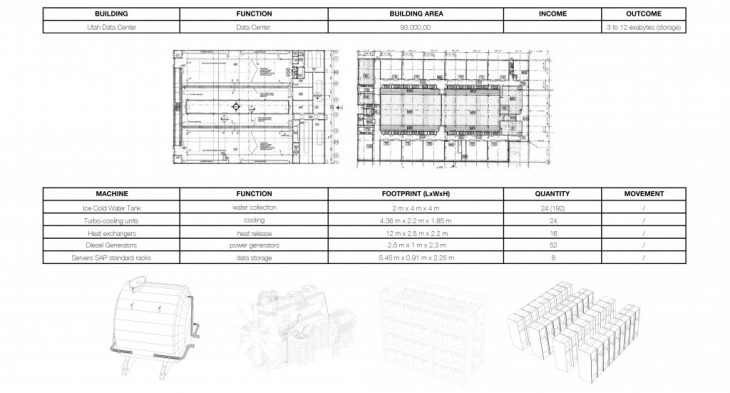

Utah Data Center – Data Center

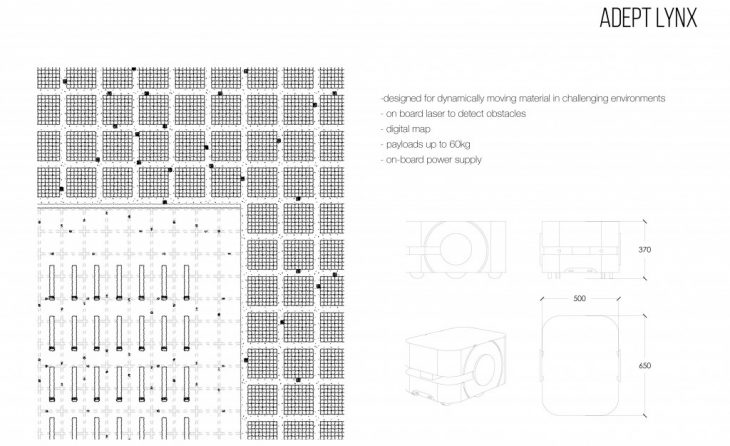

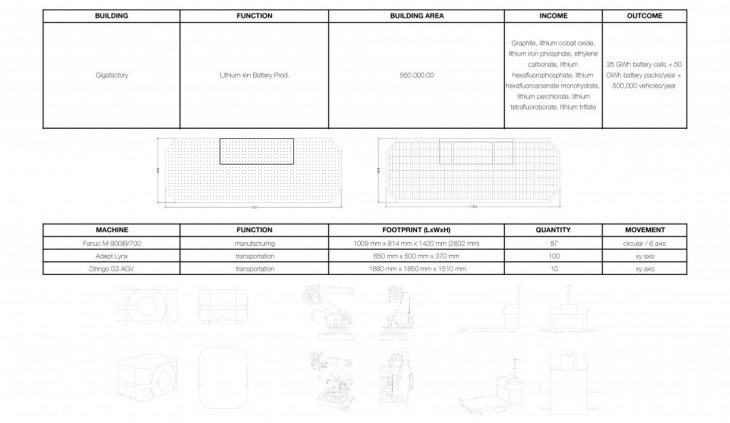

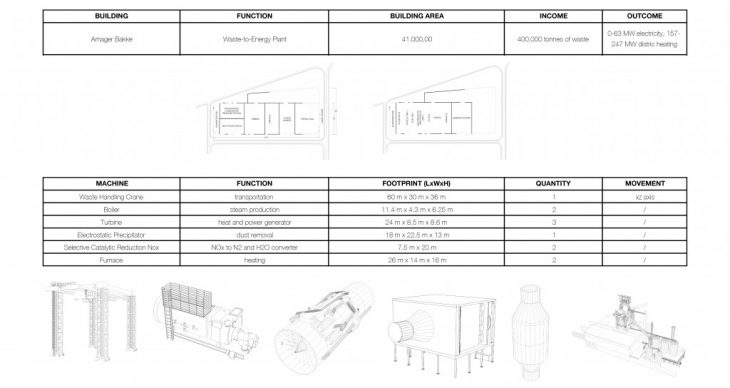

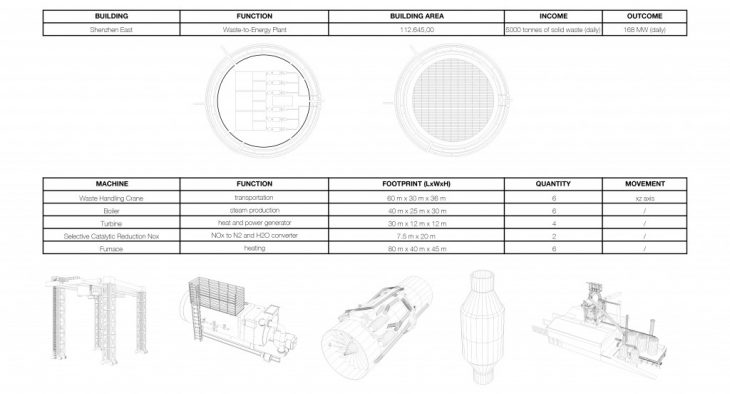

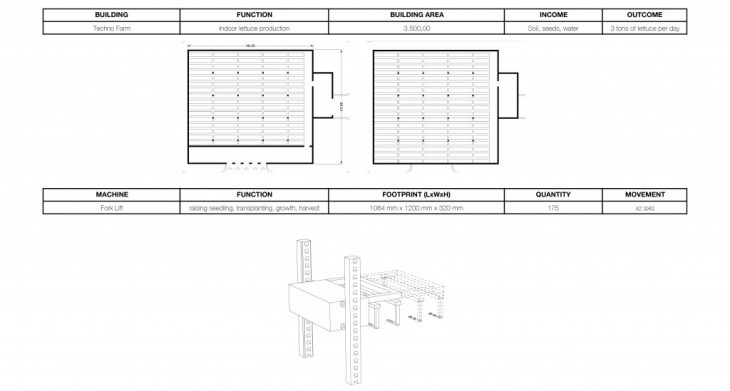

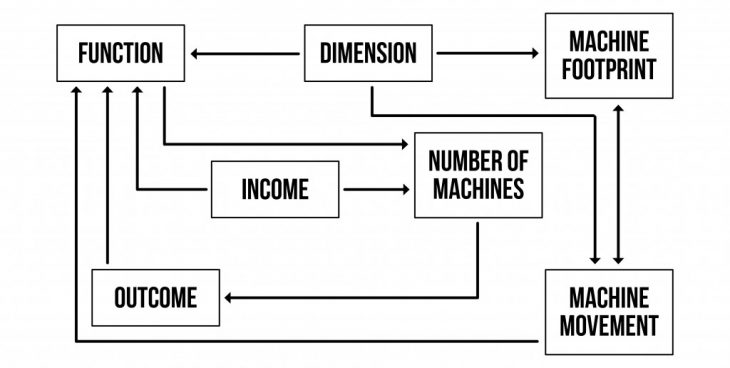

The thesis started with a research on some of the most automated existing industries of different typology of productions and different locations around the world. Each case study was analysed in terms of building features (area, layout, income, outcome) and machine characteristics (typology, footprint, movement, quantity).

Mountpark Airport City

Amazon Fulfillment Center

Gigafactory

Lithium-ion Battery Factory

Amager Bakke

Waste-to-Energy Plant

Shenzhen East

Waste-to-Energy Plant

Techno Farm

Indoor Lettuce Production

Impossible Foods

Plant-based Meat production

Utah Data Center

Data Center

Autorotor Farm

Dairy production

PARAMETRIC DESIGN

The parameters collected in the research were further analysed to understand the numerical ratio between income-outcome and number of machines used, to adapt the outcome needs to the population of the Metropolitan Area of Naples.

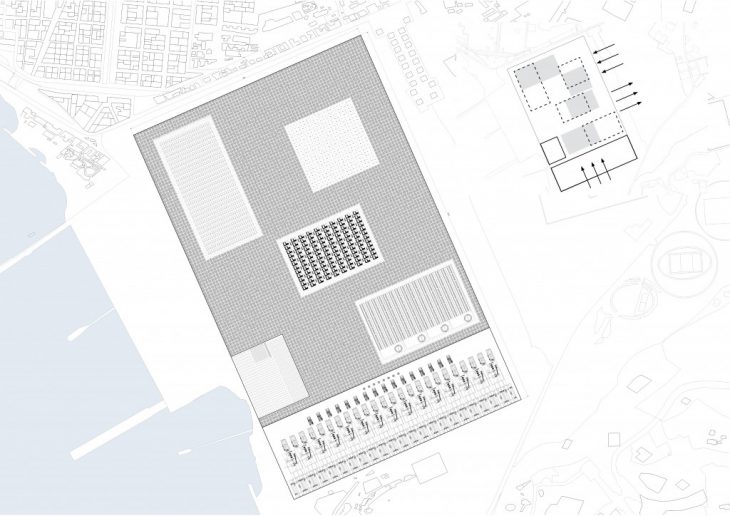

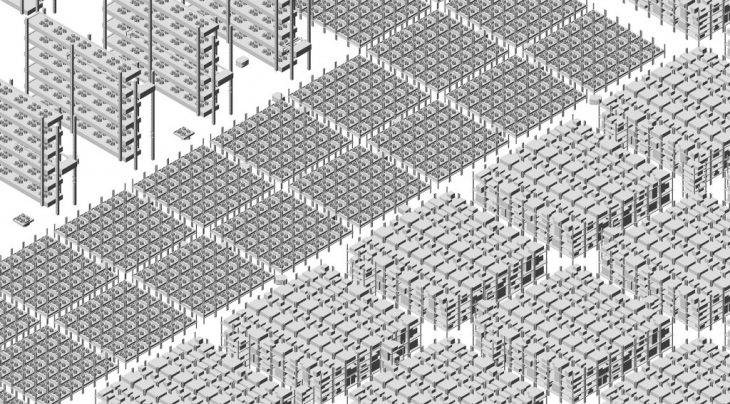

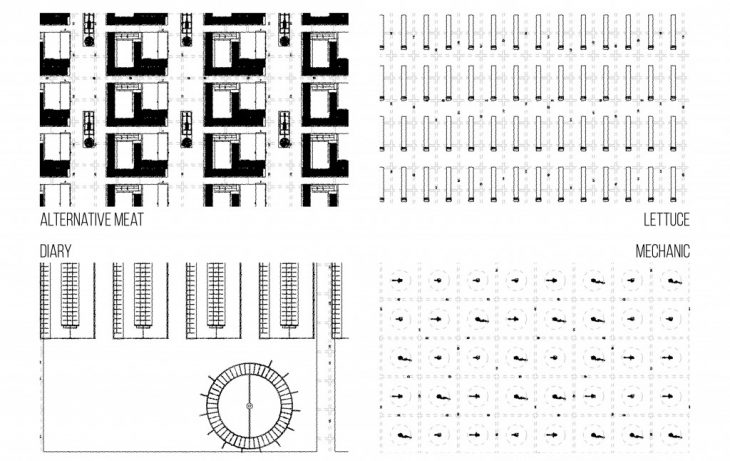

Furthermore, the relationship between the parameters collected was defined, with the aim of highlight which ones could be taken to create the parametric design of the system. Each program is designed by the number of machines, movement and location in relation to each other.

TRANSPORTATION SYSTEM

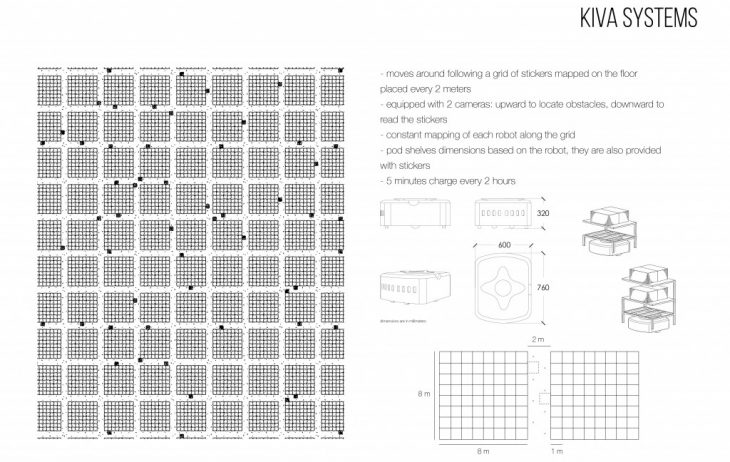

The transportation system is created by the movement of the Kiva system robot and defined by a 2 m wide corridor grid spaced out by the 8 m by 8 m storage shelves.

The transport system works on stickers placed along the grid, which can be activated and deactivated, giving the opportunity to create a dynamic system of production by defining dynamic and static programs, according to the outcome, income and production time necessities.

STATIC PROGRAMS

The Data Center program represents the coordinating system in control of the movement of the machines. It needs to be located near water, which is utilized to cool down the system.

The Waste-to-Energy program runs as the energy production system for the productive building, receives a continuous amount of waste from the city, which is burned and transformed into energy before being distributed around the whole system. It requires a static position along the edge of the building area.

DYNAMIC PROGRAMS

The alternative meat production program provides the production of 4.36 milion burgers per week.

SECONDARY TRANSPORTATION SYSTEM

GENERAL PLAN

The plan view of the building is composed by the circulation grid, punctuated by voids and singularities which are represented by the different production programs and machines.

The diagram in the upper right corner shows the still position of the static programs and the potential movement of the dynamic programs, according to the income and outcome areas on the borders.