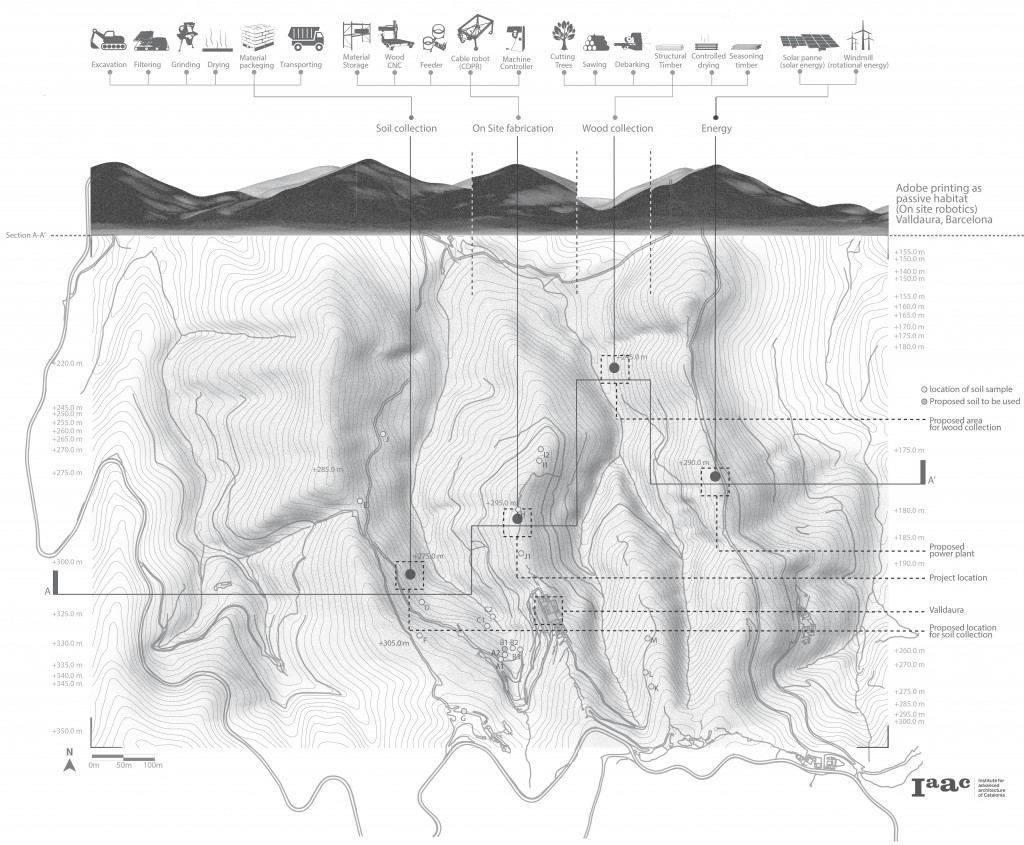

Figure: Self-sufficiency, connectivity of material process, renewable energy production and on site fabrication

Architectural practice, building technology, industry and manufacturing process increasingly adopting and integrating the contemporary advancement of technology of 3D printing, digital fabrication, robotics and automation in construction in different scales. Additive manufacturing(AM) derived by CAD software’s leading architects and designers to create more complex geometry, optimizing shapes, materials and energy more precisely within very short time. AM is still growing while it is rapidly adapting new technologies which gradually advancing construction policies, mass manufacturing process and creating new bridges between industry, contractors and architects.

Figure: Soil sample collection from various location around the site

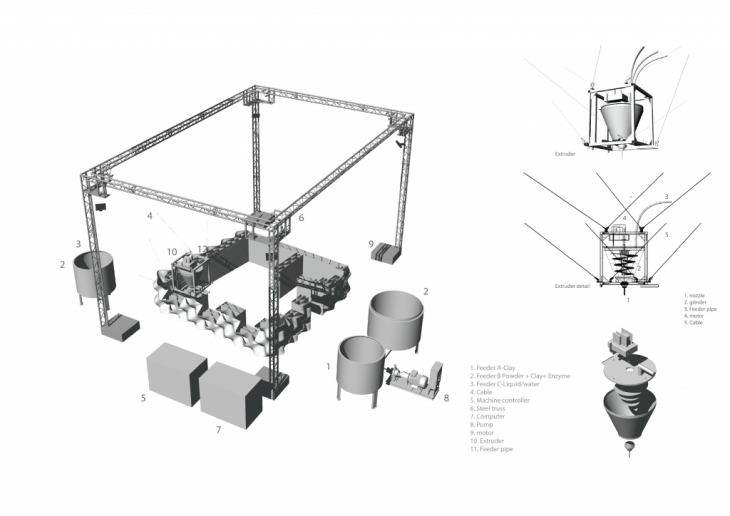

Figure: On-site fabrication with cable driven parallel robot

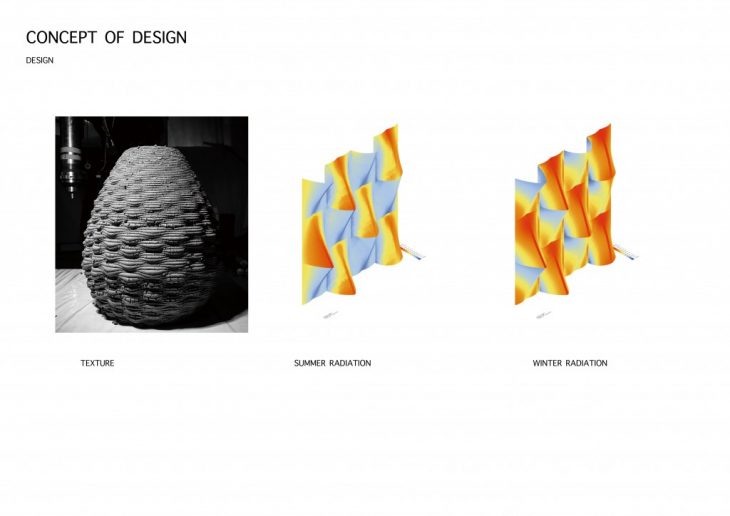

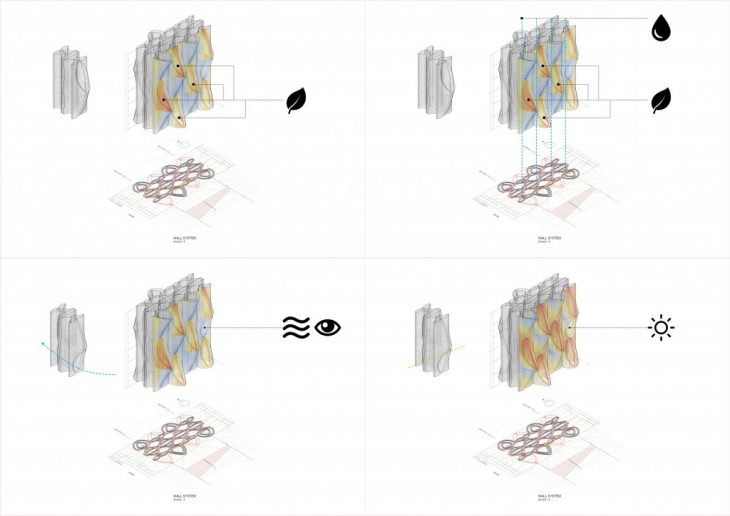

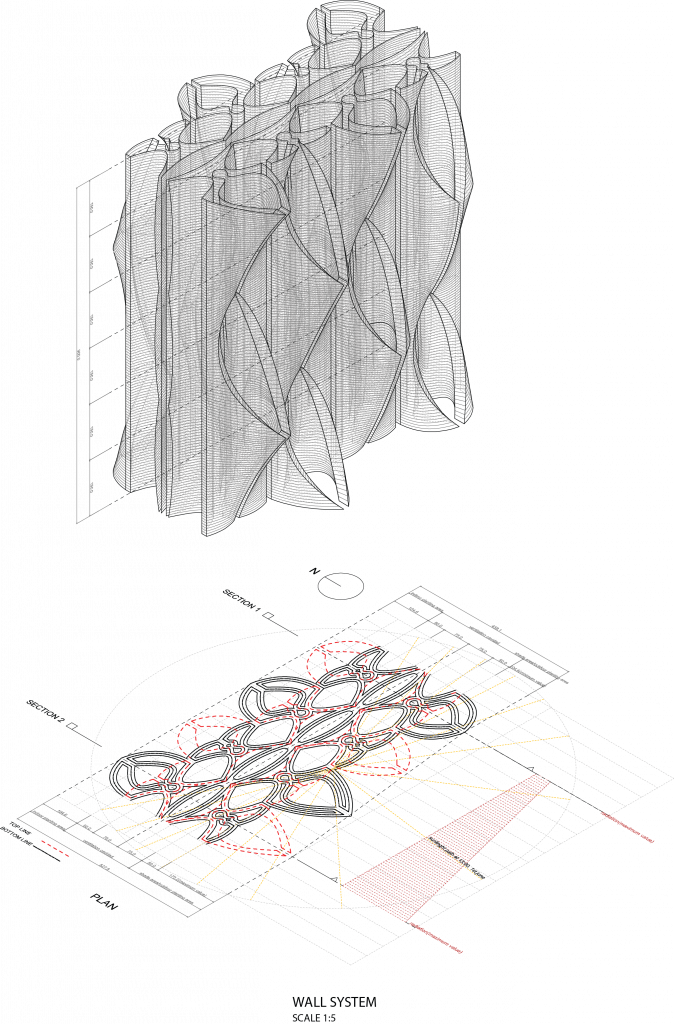

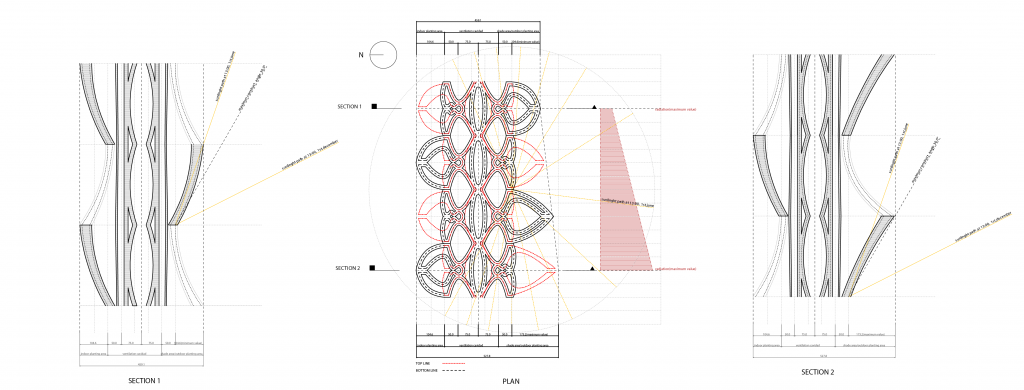

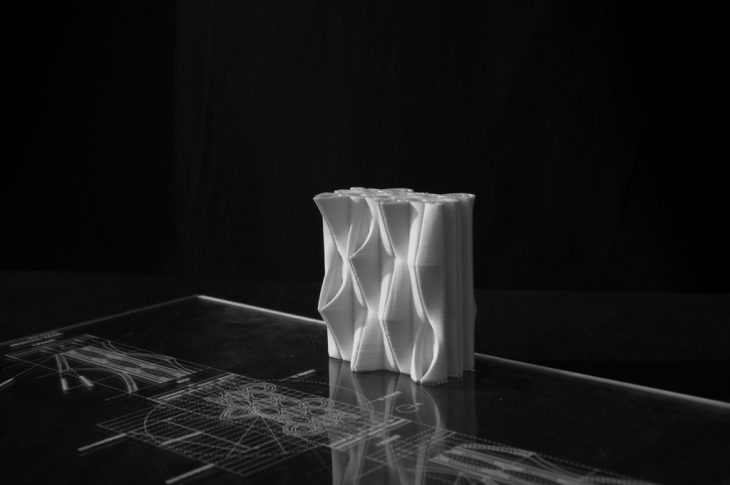

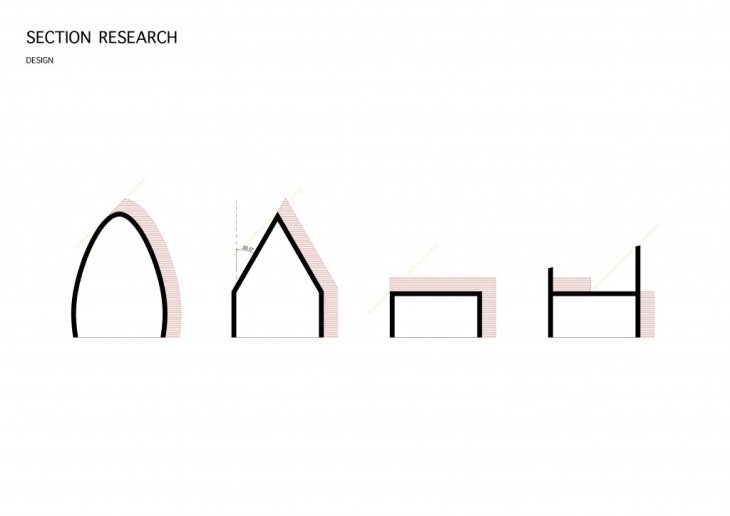

Figure: Parametric modelling of wall system, self shadowing geometry based on solar radiation with cavity and insulation

Figure: Parametric modelling of wall system, self shadowing geometry based on solar radiation with cavity and insulation

Figure: model of wall system

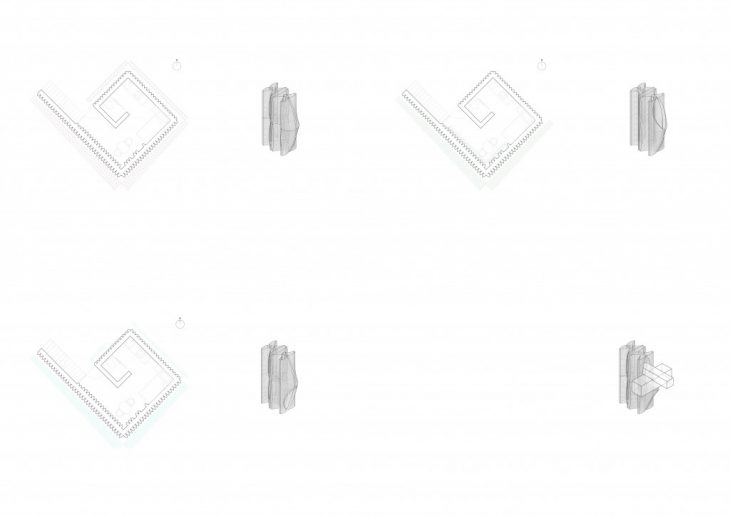

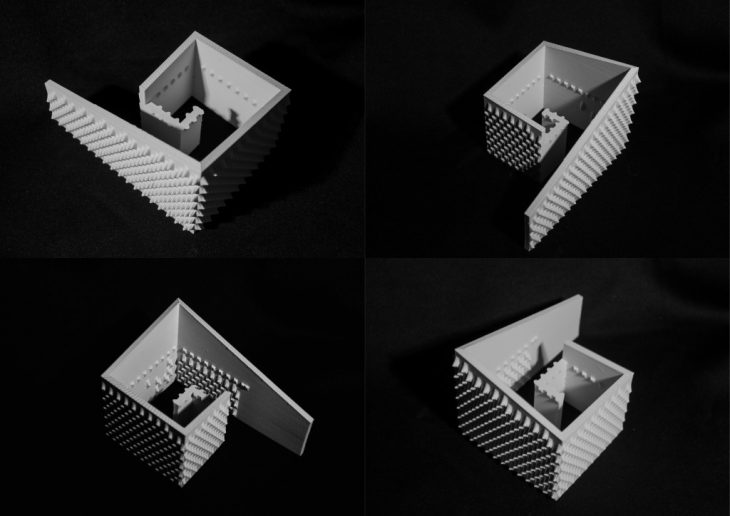

Figure: model of building

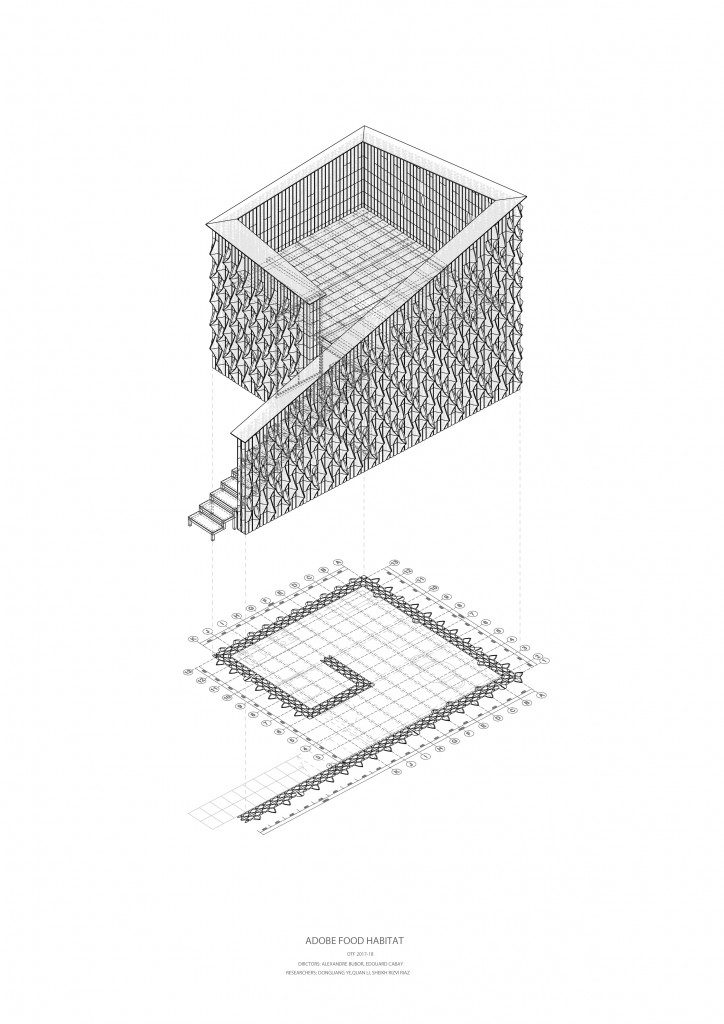

Figure: ISO of building

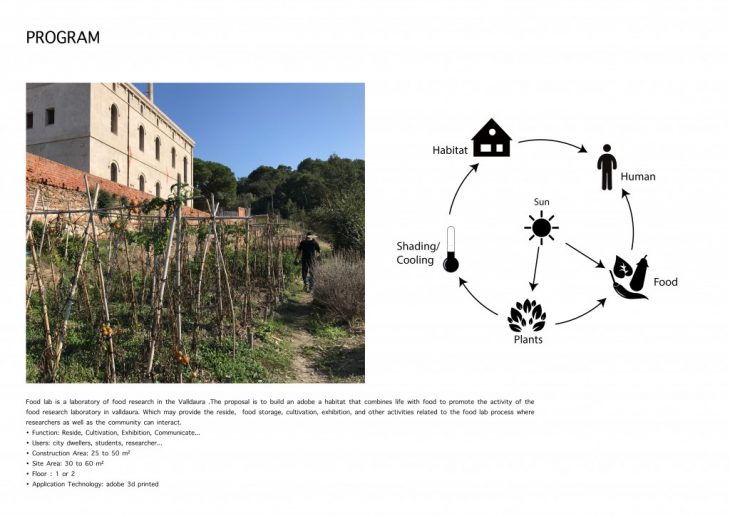

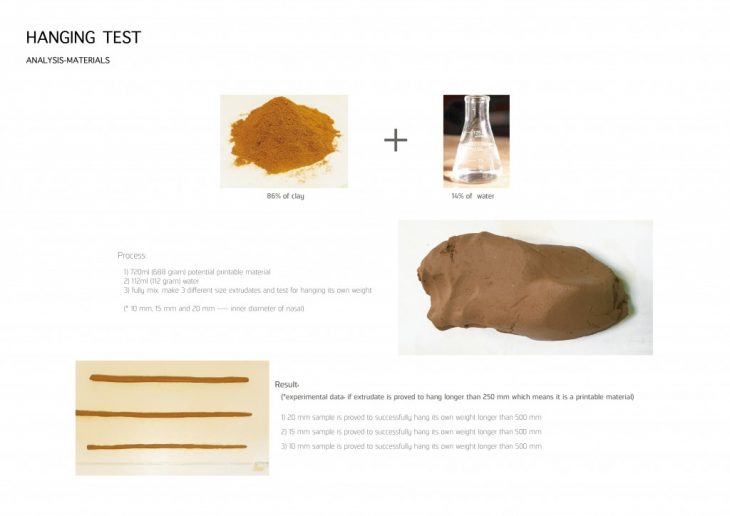

The strategy of this project is to explore the potentials of large scale 3d printing of clay by designing a passive habitat. As the site located at Valldaura natural park, a mountain location in Barcelona characterized by a humid climate with a mild, humid winters and warm to hot summers. The proposal is an individual habitat embedding food production system in the architectural design, combining accommodations and food storage, cultivation, exhibition, and other activities related to the food lab process where researchers as well as the community can interact. Another important aspect is to make adobe printing process more self-sufficient, by using locally available clay which is natural and biodegradable, consist minimum waste and which has good thermal inertia. And also, to generate renewable energy on another location in closest distance at a possible high mountain area where it has enough sunlight and wind which can produce enough renewable energy that can be used for the construction process. Different climatic strategy is explored to define the global geometry, to ensure the use of passive solar energy and to optimize heat gain by creating self-shadowing surface based on solar radiation through computation. In the wall system controlled thermal cavity and insulation is designed to ensure thermal comfort of interior. Seasonal plants are arranged on specific surface to reduce solar radiation. The fabrication strategy is based on the use of a cable driven parallel robot(CDPR) with an integrated CNC control to automate the movement of a 3D extruder.

Programme: Open Thesis Fabrication 2017-18 (OTF), Program Directors/Research Advisors: Alexandre Dubor, Edouard Cabay, Mathilde Marengo

Team: Dongliang Ye, Quan Li, Sheikh Rizvi Riaz