‘Still Alive’ is a data-based process to produce new solutions from waste material. Using computer vision, autonomous fabrication, robotics, and generative design process our aim to convert existing ‘waste’ materials to a resource based on the upcycling process.

‘Still Alive’ is the new way solution to transform un-standard material of waste into a new resource for the construction sector. Rather than to use extra energy, cost, and chemical process on natural material, we upcycle the material in energy-intensive processes. Our solution is adding value on the waste material through a process of ‘autonomous’ 3D scanning and robotic fabrication.

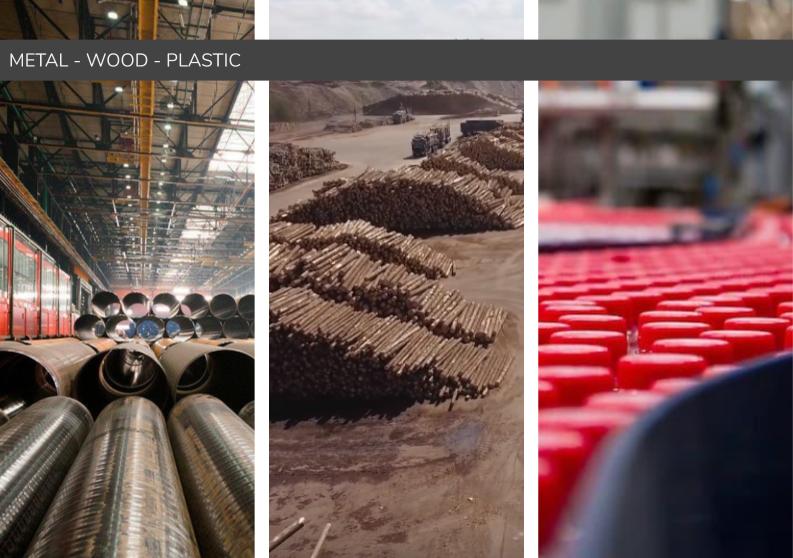

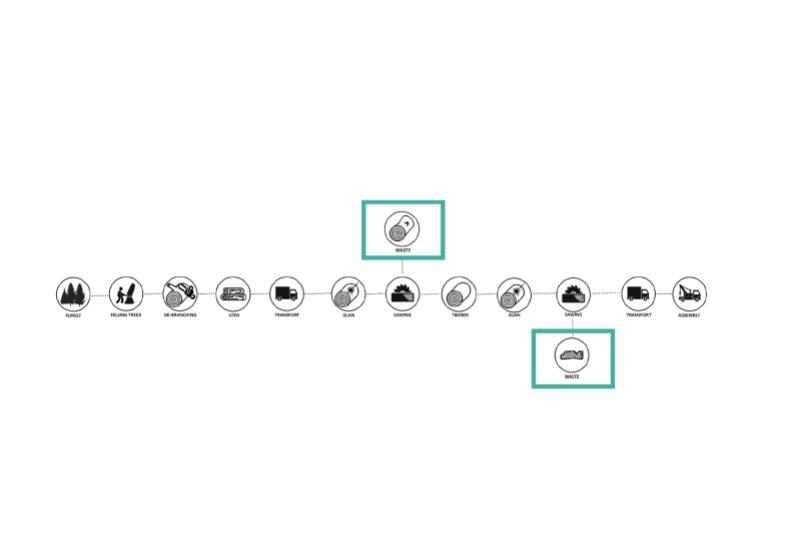

Construction Waste :

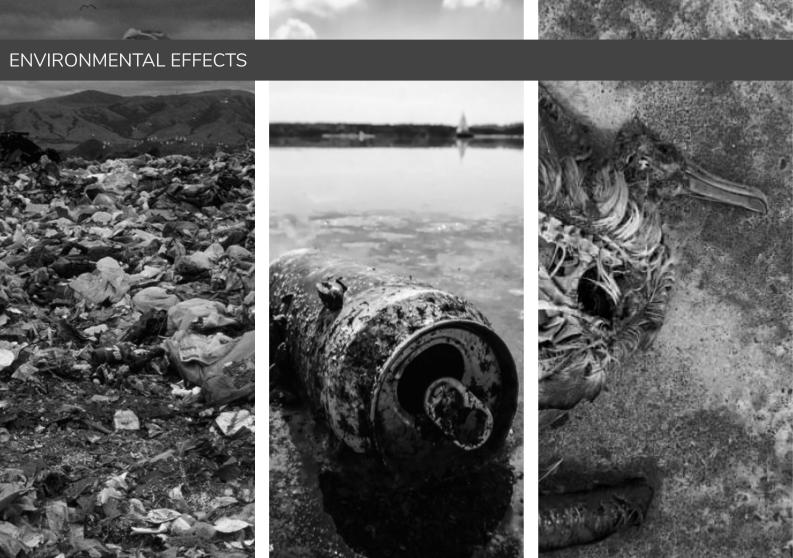

Construction waste material refers to the materials from the construction location that cannot be used for construction purposes and must be removed for many reasons. In the implementation of a building construction project, it can be avoided the residual of construction material or commonly called construction waste. Besides effects on the cost, construction waste also affects to the environmental.

Some of the notable research included that the EPA estimates demolished buildings contribute 1 Billion feet of usable lumber per year. It also states that 58% of that timber would end up in the landfill. It became clear very quickly to us that this was a big problem to tackle with huge potential and impact.

- 35 % ( or 136 million tons ) of waste generated each year from buildings, construction, and demolition.

- 1 billion feet of usable lumber per year from demolished buildings.

- 58% of timber ends up being thrown away and going to the landfill.

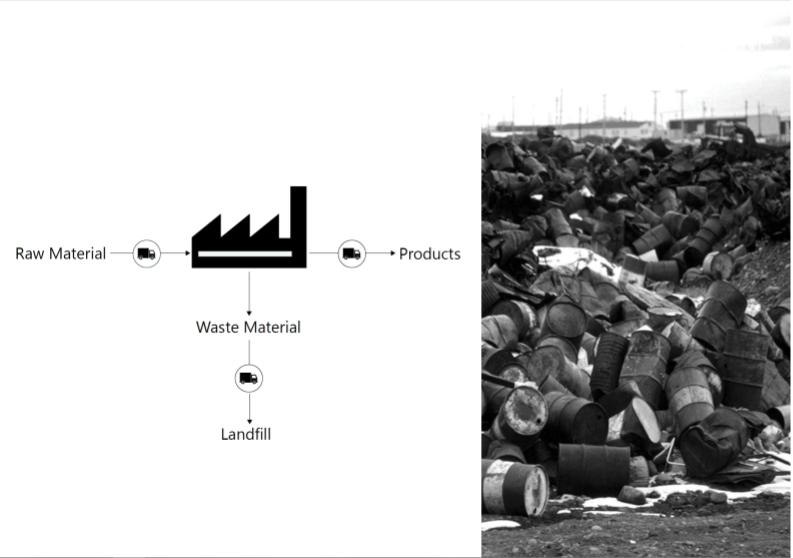

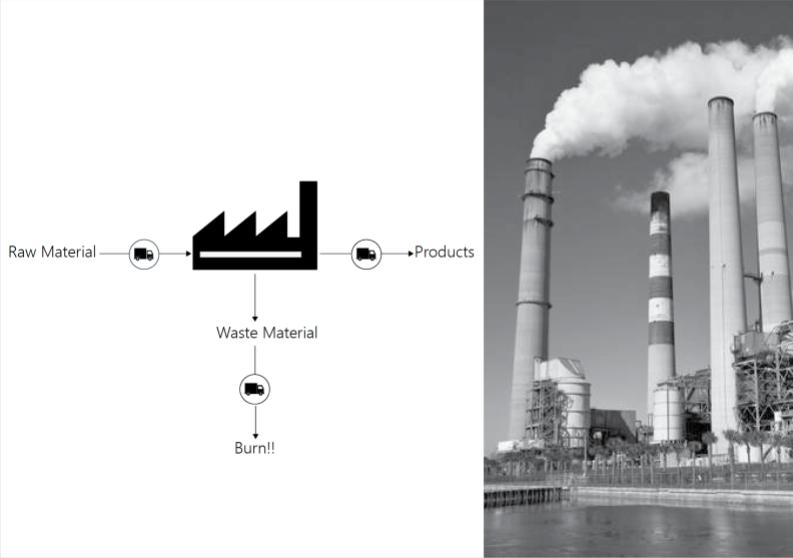

WHAT IS THE SOLUTION FOR WASTE MATERIAL?

HOW CAN WE SOLVE THE WASTE PROBLEM IN A PHYSICAL WAY?

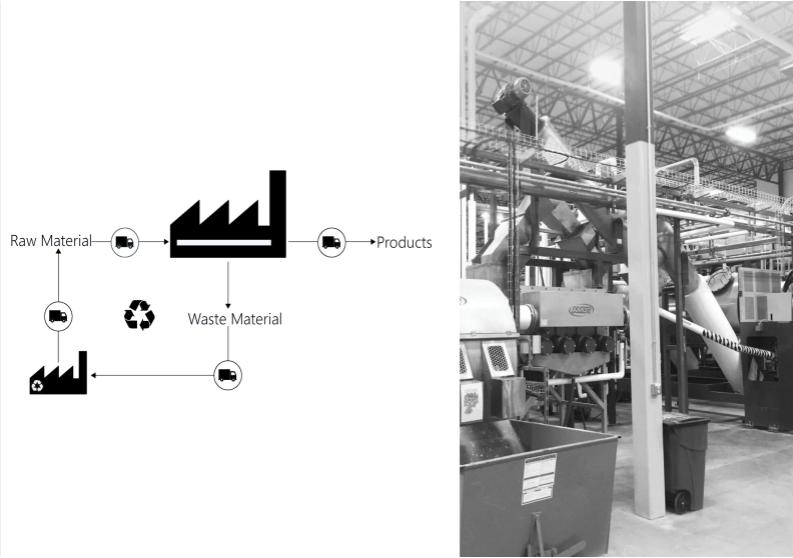

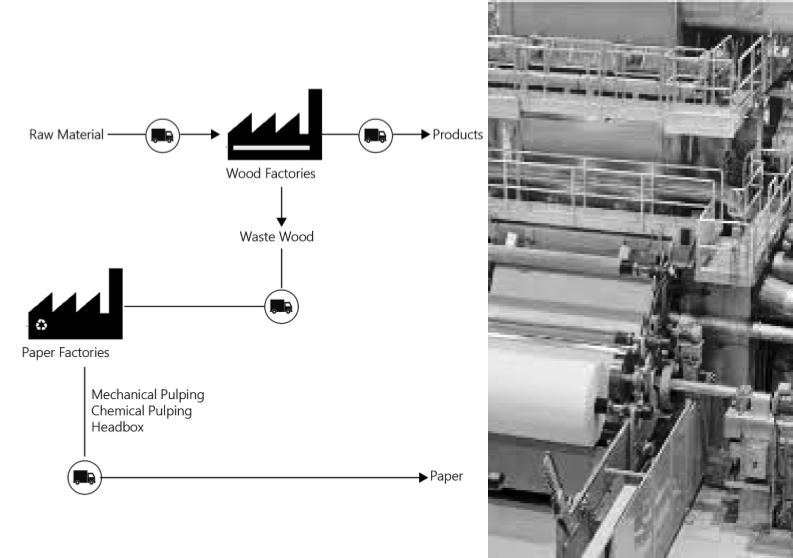

Recycling Waste Material

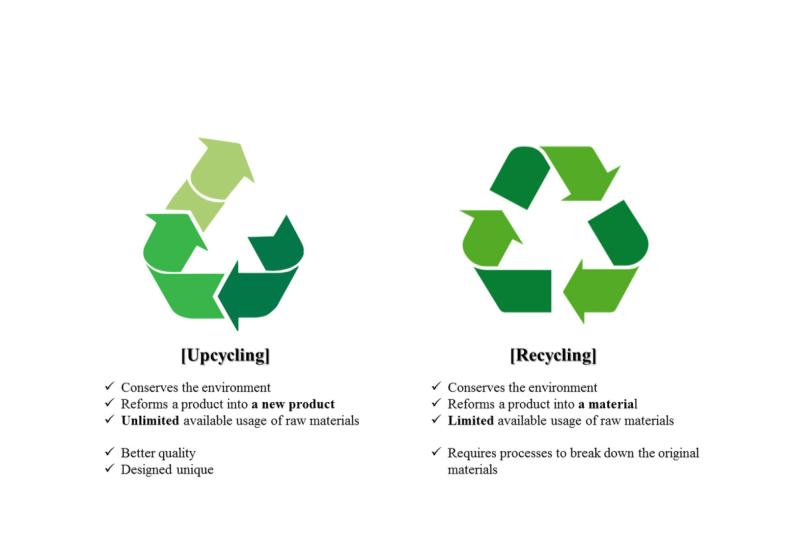

Recycling is the process of converting waste materials into new materials and objects. It is an alternative to “conventional” waste disposal that can save material and help lower greenhouse gas emissions. Recycling can prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, thereby reducing: energy usage, air pollution, and water pollution. recycling aims at environmental sustainability by substituting raw material inputs into and redirecting waste outputs out of the economic system.

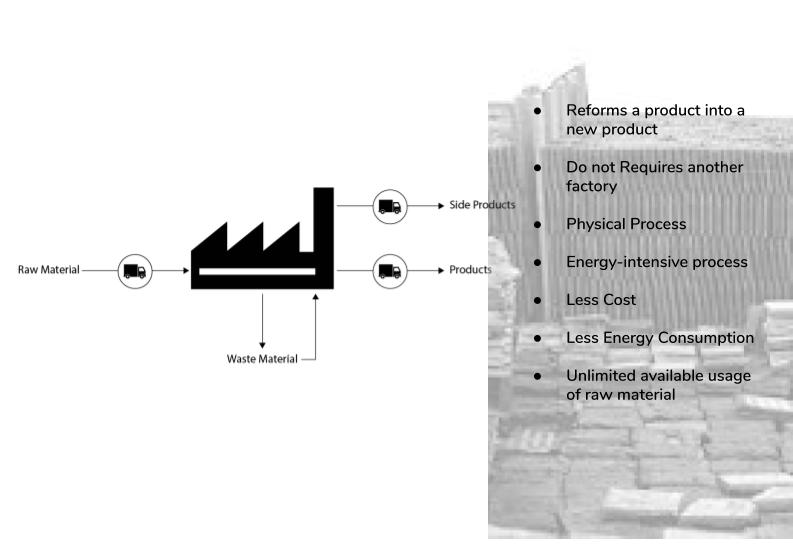

Upcycling Waste Material

Upcycling is the opposite of downcycling, which is the other face of the recycling process. Downcycling involves converting materials and products into new materials of lesser quality. Most recycling involves converting or extracting useful materials from a product and creating a different product or material. the goal of upcycling is to prevent wasting potentially useful materials by making use of existing ones. This reduces the consumption of new raw materials when creating new products. Reducing the use of new raw materials can result in a reduction of energy usage, air pollution, water pollution, and even greenhouse gas emissions.

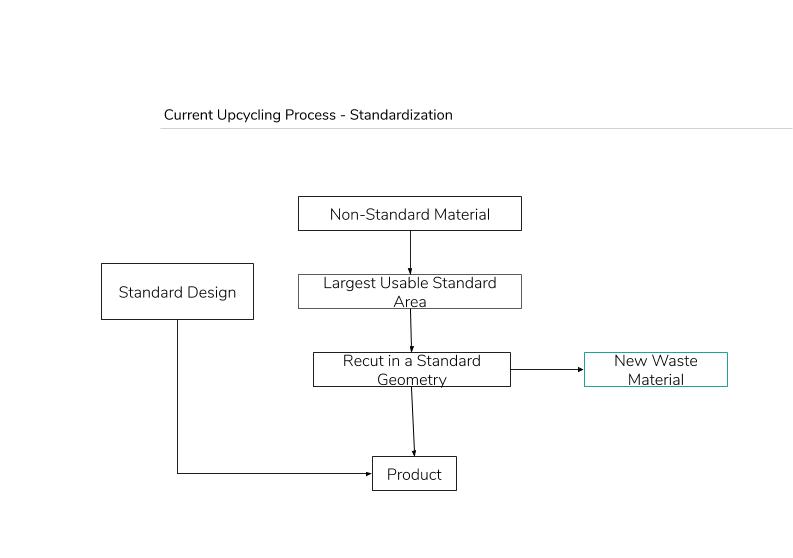

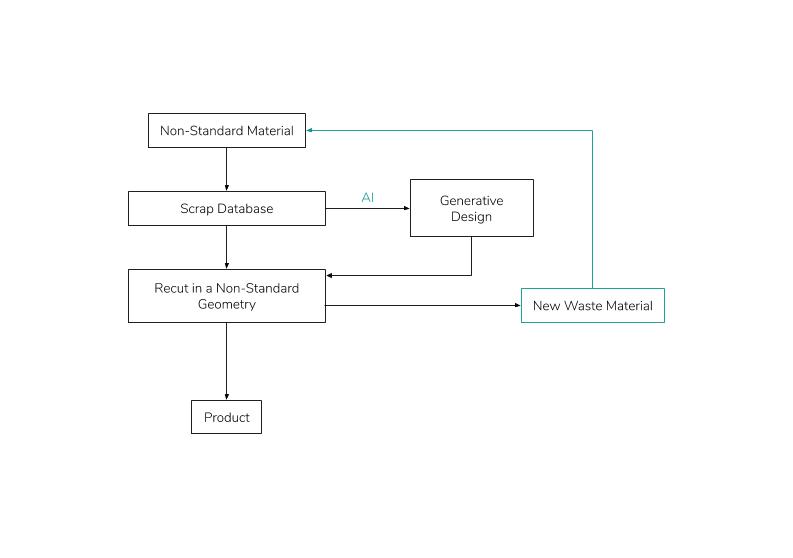

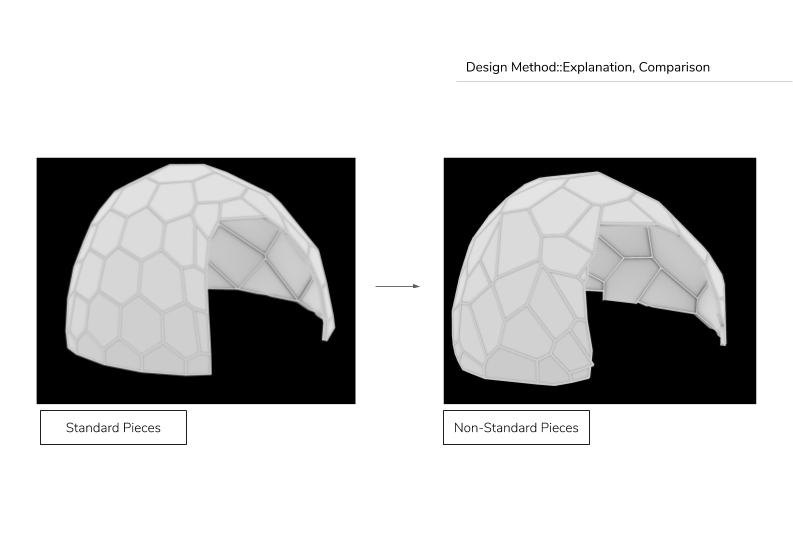

New Solution of Upcycling Process / Non-Standardization

Still Alive is the data based process to produce new solutions from waste material. Using computer vision, autonomous fabrication, robotics, and generative design process our aim to convert existing ‘waste’ materials to a resource based on the upcycling process.

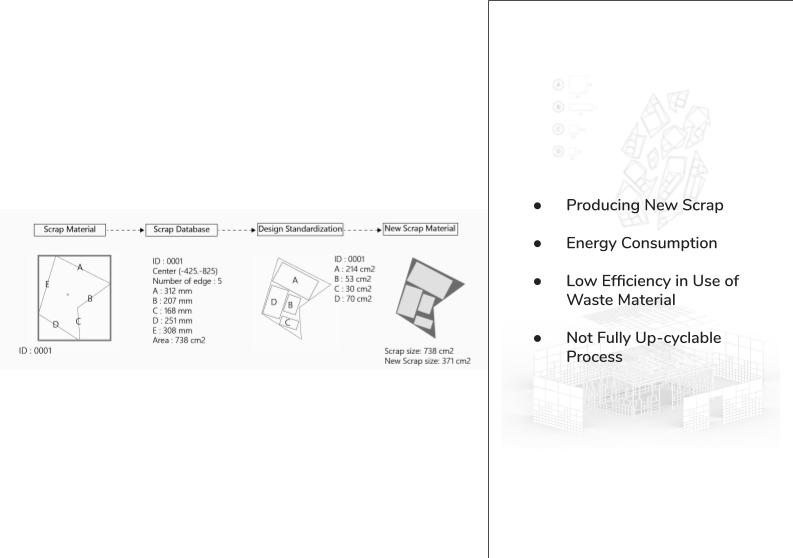

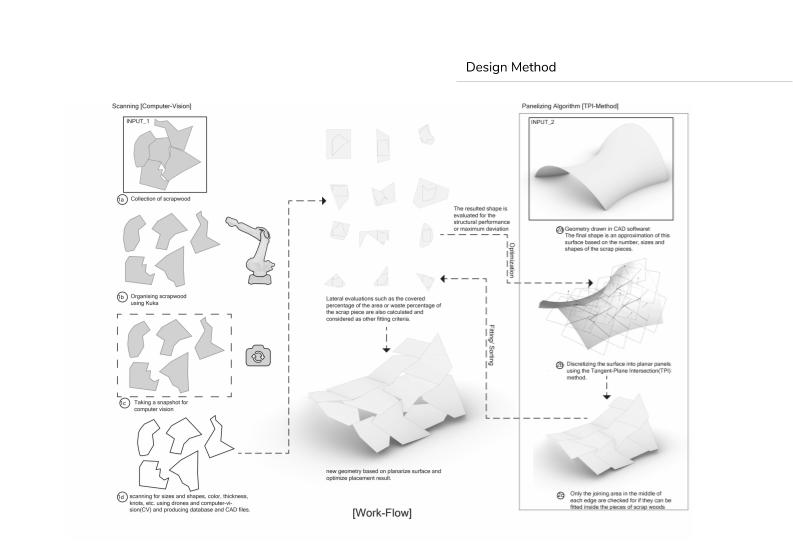

Autonomous Scanning

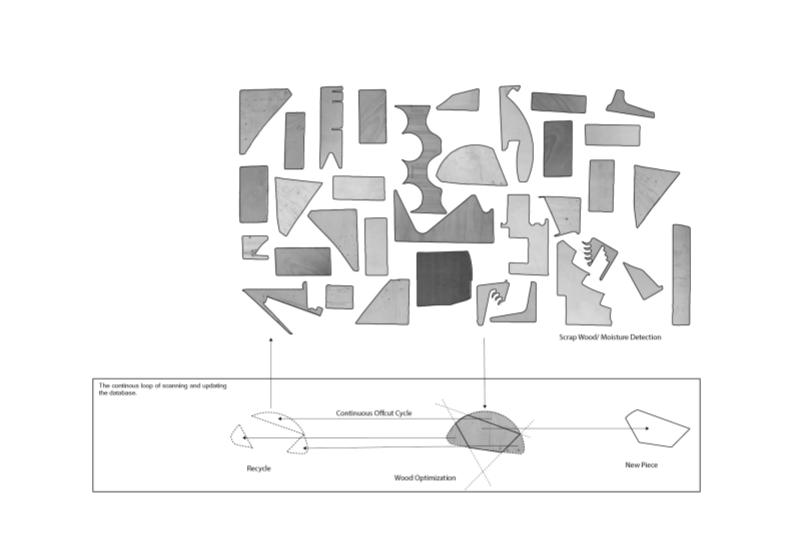

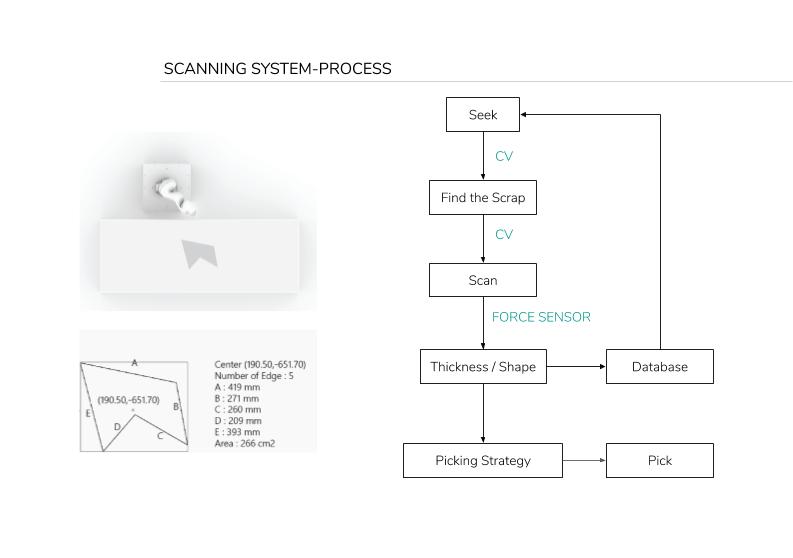

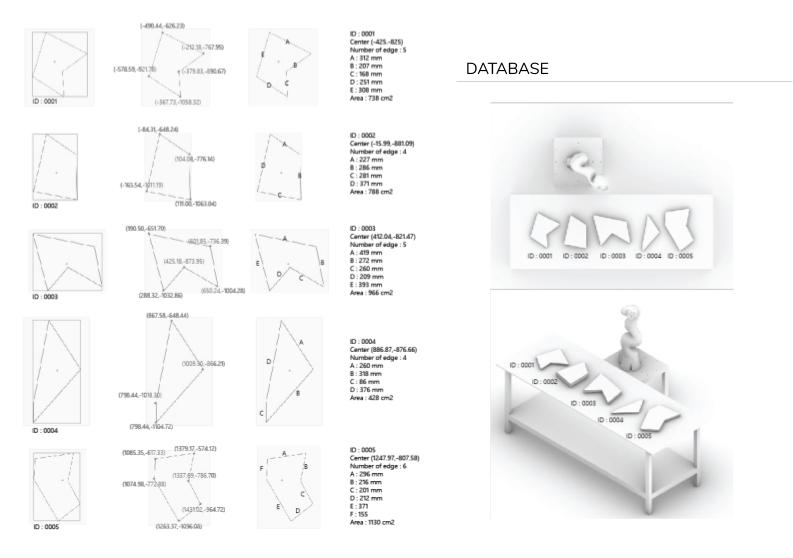

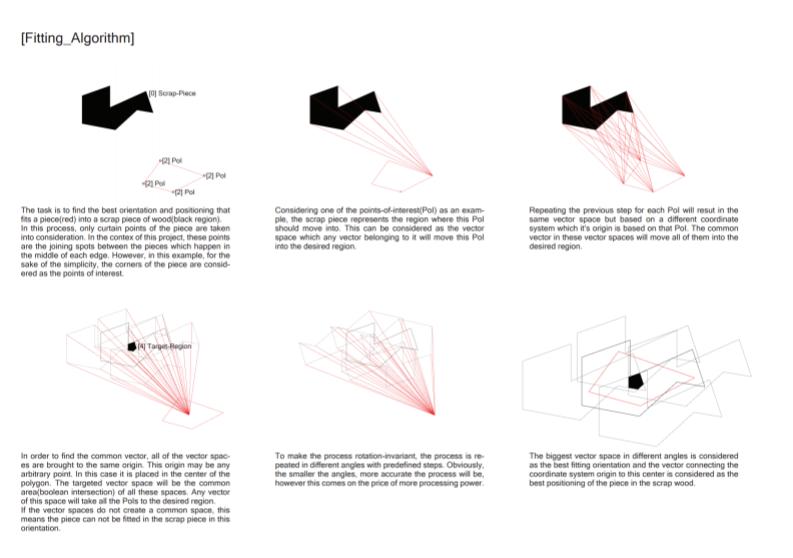

In a non-standard process, each piece is unique. So first we need to know our material to extract data from it. Therefore we need to scan every piece of material. But for the industry, we will be dealing with a huge amount of material. So we need this system to be autonomous and reliable. Beside of that, the manual process is out of the question due to the scale.

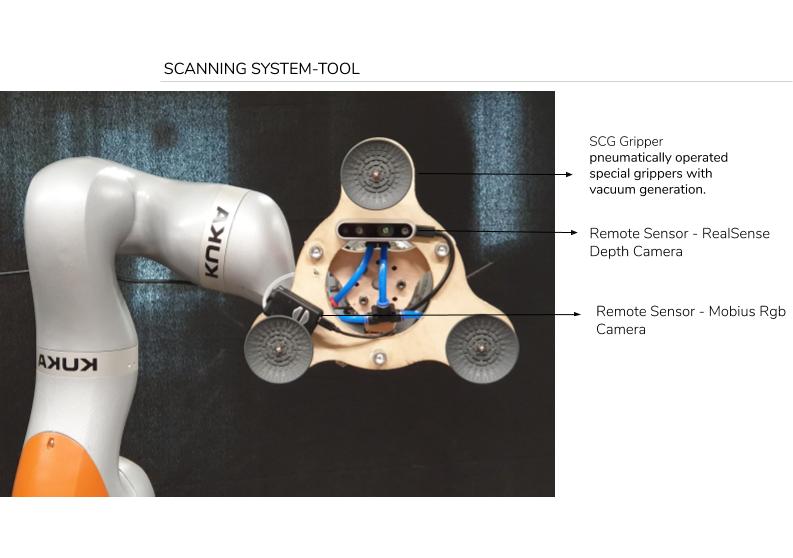

To demonstrate this process we set up a system to implement this idea over an example of scrap woods. In our case, we deal with different shape of waste material. We extract the information into a database by autonomous scanning. Using a robotic arm to find the scrap and extract the data through remote sensing saving into a database and sorting the physical material through pick and place process.

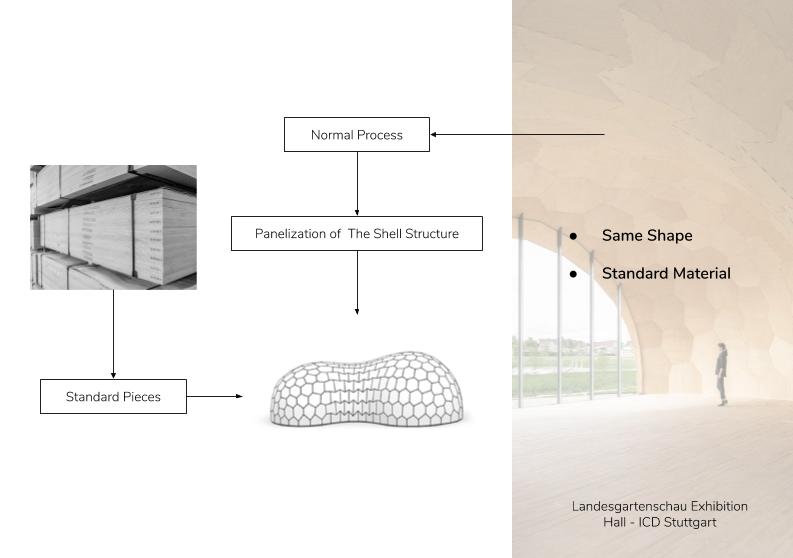

Generative Design Algorithm Reference – Landesgartenschau Exhibition Hall – ICD Stuttgart

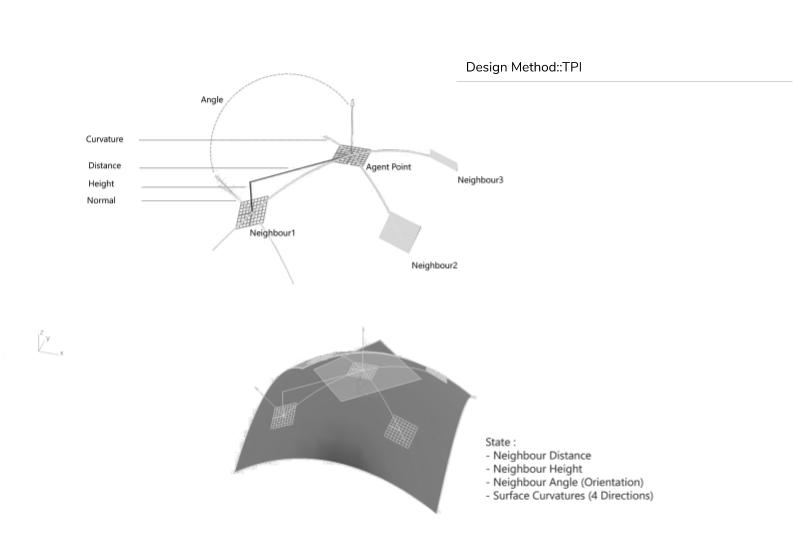

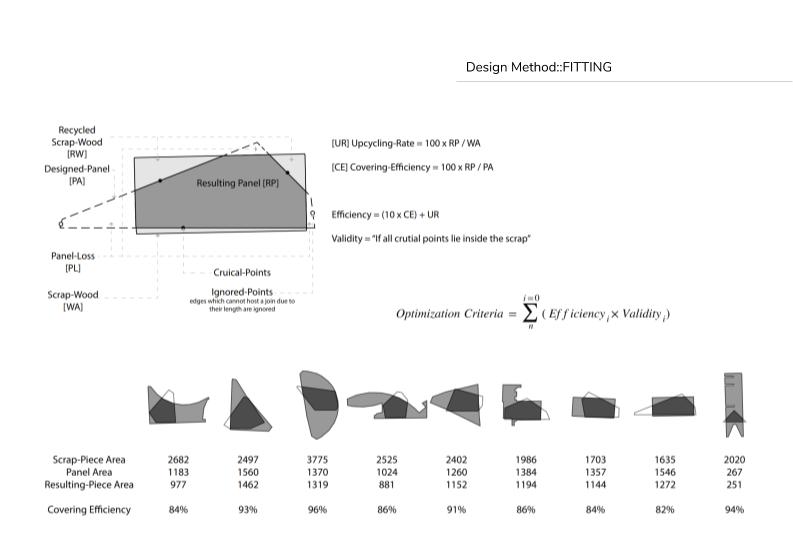

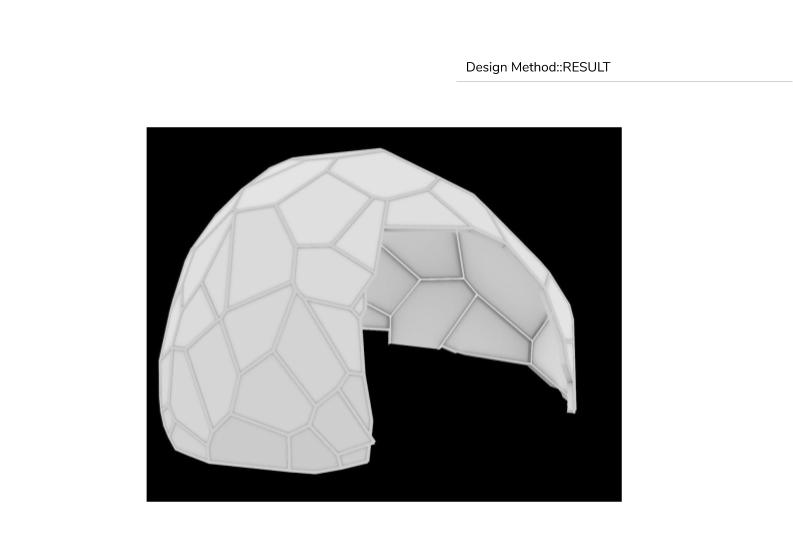

The computational design tool developed in the context of this research project offers the possibility to include material characteristics and fabrication parameters in the design process. Rather than drawing each plate manually, the plate’s design space is incorporated into a simulation and optimization process for automated form-finding, which includes parameters and constraints of robotic fabrication.

FABRICATION

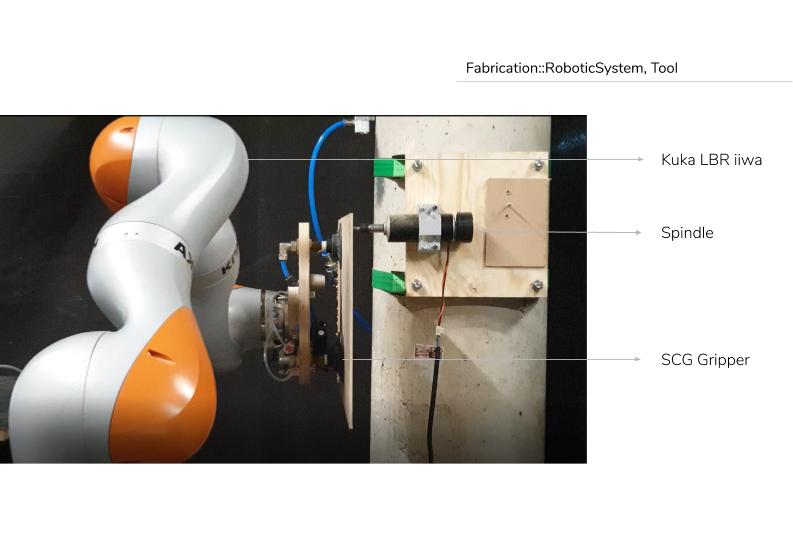

Based on the database and design algorithm we use KUKA LBR iiwa for the autonomous fabrication process. Our fabrication process develops faster and customized fabrication solution for the construction site.

After generating a database, KUKA LBR iiwa detects the boundaries of the material, calculates the dimensions and orients the tool to pick for assembly. When the picking process is done, the robotic arm transfers the piece for the milling process. Each piece of waste wood is cut according to our design algorithm to the robotic assembly strategies.

Faculty: Aldo Sollazzo – Alexandre Dubor

Faculty: Aldo Sollazzo – Alexandre Dubor

Students: Ardeshir Talaei | Hazal Yilmaz