3D Printed Skin – Eastland Town Centre

Reference Facade Background

The facade of focus for this project is the Eastland Town centre by ACME in the suburbs of Melbourne. The architects designed the facade to be a surface wrapping the upper part of the town center, which houses the library. This veil of stone controls light and view points out by manipulating the apertures.

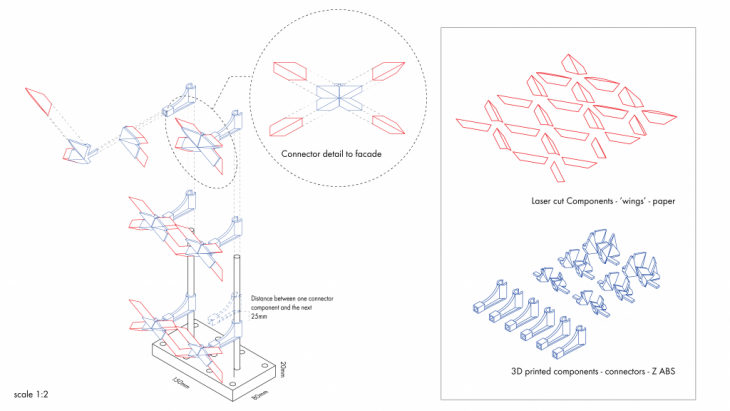

Structurally, the skin system is hung from the roof, with secure connectors to link the lower parts of the skin to the core of the building at critical junctions. As the facade’s main variable is the openings, which affects the wideness of the stone plates, the connectors are varied as well.

The facade is chosen for the 3D printing method study, as it is advantageous in quick the production of modifiable/customisable base elements. The method employed here combines laser cutting technologies to do the front elements of the facade, where 3D printing elements are applied in the production of the connective system.

Process

The design and production process of this project required multiple adjustment steps, from the modelling of the elements to the fabrication. In this process, we will see how the model was developed for successful printing, and how the final 3D printing process requires fine tuning, even with an adapted geometry.

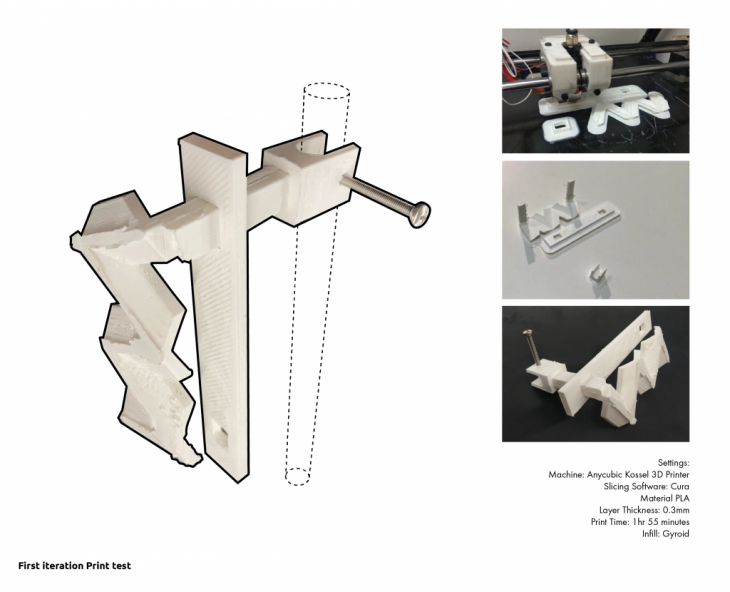

First iteration and tests

The first iteration attempted to link many of the elements into one printable object, which proved not so efficient, nor did it represent the facade system correctly. However, this first iteration provide insight into working with the 3D printers and the materials. In the first iteration, the project used PLA, in the final iteration, the project switches to Z-ABS.

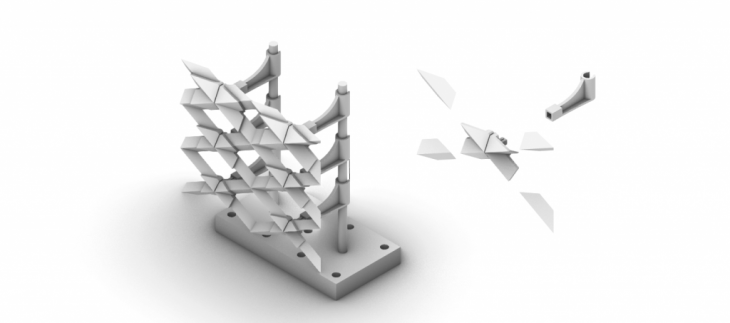

Modeling the final iteration

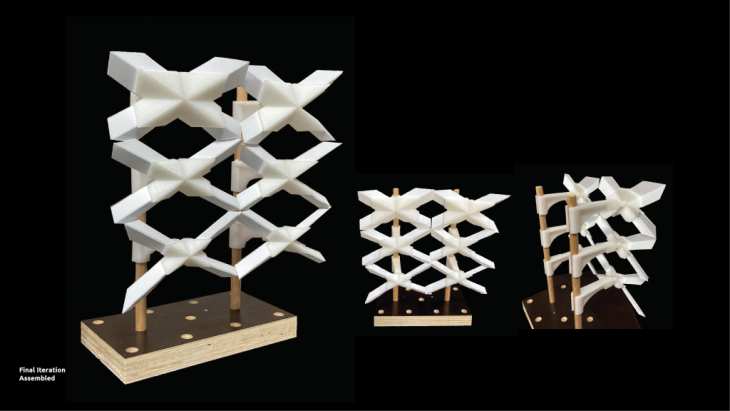

The approach for the final iteration consists of 3D printing holders to hold the paper ‘wings’ – or stone slate. The paper wings are slotted into place. And the facade elements are then slotted into the 3D printed connectors which link the installation back to the base model.

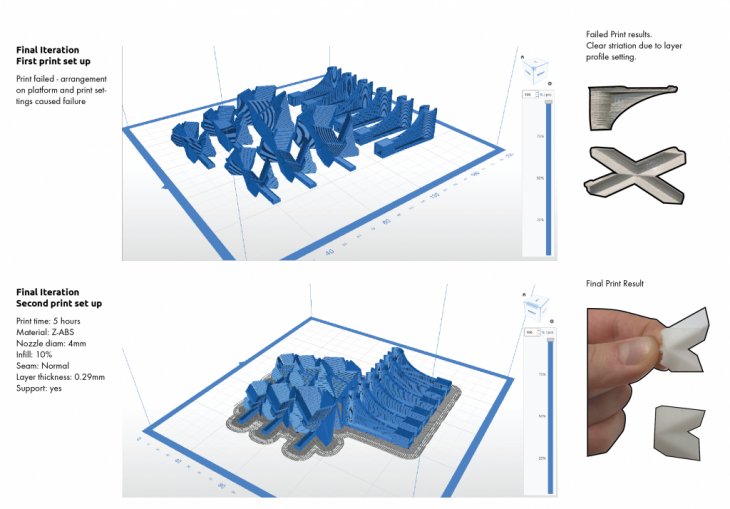

Fabrication Process

The final iteration employs a combination of laser cut elements to make up the stone slates in the building’s final facade. These laser cut elements are folded and inserted into the 3D printed model.

The 3D printing fabrication process required fine tuning to create a final output that achieved a high quality finish.

Result

This project was done based on the code development in Animated Systems – a Computational Design course. A brief overview of the project can be viewed here.

</p>

3D Printed Skin – Eastland Town Centre is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at the Master in Advanced Architecture in 2020/2021 by Students: Lekha Gajbhiye, Matvei Genne, Cecile Ngoc Suong Perdu

Faculty: Ricardo Mayor Luque, Lana Awad and Shyam Zonca.