Interactive 3D printing – Rob|Arch 2016 Workshop

Robotic fabrication processes enable designers and architects to explore the boundaries between digital and material worlds. Beyond optimization criteria or parametric design, new design strategies such as generative design and collaborative design are enabling new ways of approaching material exploration through robotics. Typically, the outcomes of a fabrication process are predetermined, however, with the introduction of sensors, design and fabrication process may be interrupted by real-time feedback. The Interactive 3D printing workshop explored the potential for creative practitioners to adopt robotic fabrication processes augmented with the introduction of sensors. Using an inexpensive toolbox of sensors useful for digital fabrication, participants in the workshop have constructed and integrated sensing apparatus into a 3D printing process to explore the role of material feedback in an on-going design process.

Interactive 3D printing – Rob|Arch 2016 Workshop

Sensors and Robotic Fabrication: a Real Time Interaction

The emergence of real time interaction between sensors and robotic fabrication environments has led to a plethora of experiments that expand traditional robotic fabrication approaches where the robot merely executes a program that represents the end result of a design process that took place at an earlier phase. The workshop sets out to challenge such long established notions of design as an abstraction of making by involving multiple forms of feedback during the actual robotic fabrication process. Design and making conflate into the same time and space – questioning the very essence of design, and pointing to a new model of digital robotic craft.

In the workshop participants have used real time data to shape the robotic generation and manipulation of small ceramic modules that have been produced on multiple robotic stations. Small teams of participants have been developing individual modules designed and printed in a constant negotiation of overall collective design moves (e.g. the wall and its pattern and appearance), sensor input (randomly curated external content), and the personal design interests participants have brought to the workshop (subjective design values such as structure and other). The process involved both technical (sensor to robot) as well as personal interactions (negotiating designs). The unpredictable end result was at the outset, has not been conventionally modelled, and thus serves as an investigation of bottom up and top down design approaches.

The Rob|Arch conference series is a collaborative effort between the co-hosting universities, industry partners, and the Association for Robots in Architecture. Rob|Arch 2016 is taking place in Australia, one of the current hotspots in robotics in the creative industry.

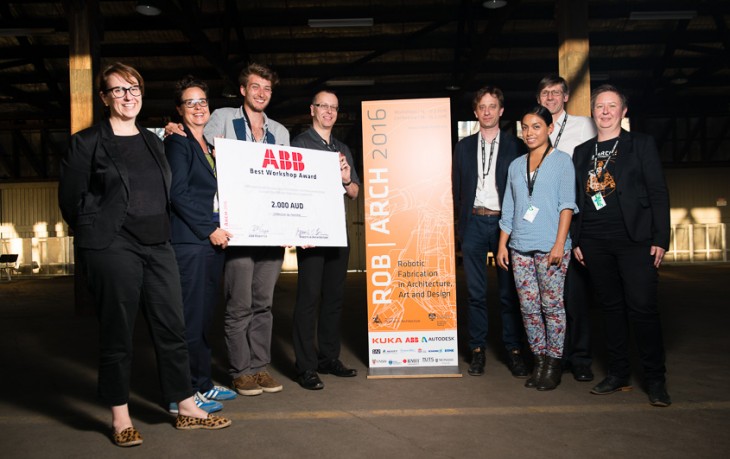

Interactive 3D printing – Rob|Arch 2016 Workshop is a collaboration between the Institute for Advanced Architecture of Catalonia (IaaC), Usyd, UNSW and Harvard and has been awarded as Best Workshop of the 2016 edition of Rob|Arch.

The workshop team receiving the prize of Best Workshop of Rob|Arch 2016

IaaC: Alexandre Dubor, (Gabriel Bello-Diaz, Guillem Camprodon)

Usyd: Dagmar Reinhardt, Susana Alarcon Licona, Dylan Wozniak O’Connor

UNSW: Kate Dunn

Harvard: Martin Bechthold, Kevin Hinz

Students: Daniel Haarhoff, Junfeng Li, Haruna Okawa, paul nicholas, Matthew Gordon, William Ellsworth, Samuel Lewis, David Thomasson, Jose Pedro Sousa, Steve Fuchs, Adedoyin Ogunniyi, Zheyuan Zhang, Victor Martinez

Technologies

Robots: 2 x KUKA KR6-1100

Communication: Ethercat I/O +arduino + custom made Processing server, Kuka Ethernet XML, and Kuka Mx Automation

Extrusion: Potter Bot extruder + custom made Arduino control

Material: terra cotta and paper clay

Sensors: Kinect, Webcam and Arduino + light, temperature and distance sensors

Software: Rhino 3D + Grasshopper 3d + KukaPrc + Firefly + custom KRL code.

Special thanks to Johannes Braumann for the countless support on KukaPRC and the great work on Kuka Mx Automation.