Abstract

Construction error is problem not mentioned most of the time, only when huge accident caused by these errors happen, people realized the damage could be huge and painful. This paper is a research about construction errors.

The first part is a brief introduction of how serious the problem is. The second part is a research about how construction error happens in different structural types. List most typical error. Classify them and summarize several characters. The third part is a discussion about stage of art, include traditional method to control errors and latest research base on emerging technology. The research aims to have a fully understand of construction error and searching for potential method to control it.

Introduction

Construction is a complex productive process. It always requires a long time and contain a big number of steps. Failures are hard to avoid during the complex process. Some obvious errors look stupid. But you won’t laugh once you realize a whole building might be abandon just because an obvious error. Even though some errors are possible to fixed, it won’t be as easy as changing a part for a machine, more material and effort are needed to make an error won’t affect the use of whole building.

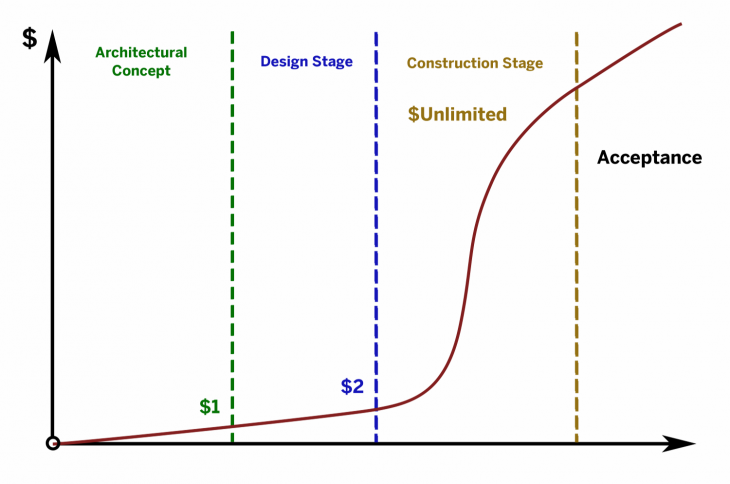

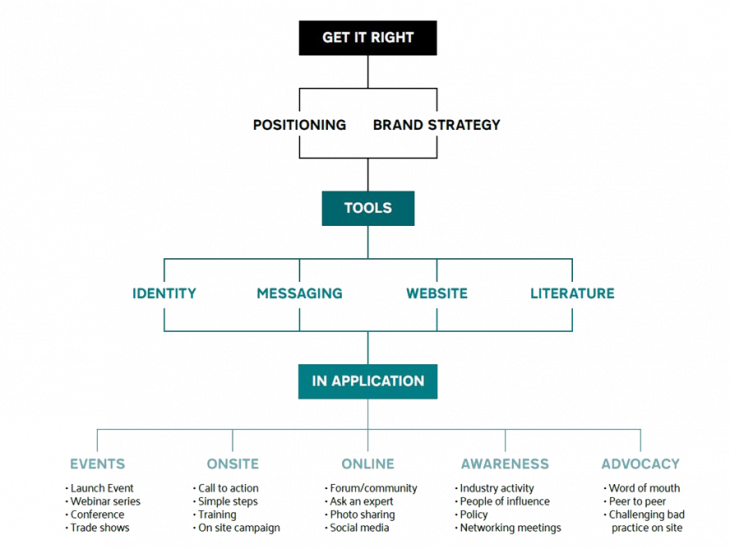

According to a report from the U.K. organization GIRI (get it right initiative). Only in the U.K., construction error cost 5bn pounds economic loss per year. 21% of total construction cost is for errors which contains latent defects (3%), indirect costs (7%), direct costs (5%), Unrecovered process waste (6%). Around the world, there are many regions has more construction than the U.K., the global economic loss coursed by construction error is incalculable.

Both design errors and constructors’ fault will lead to construction failure. Since design errors can not be control on the site, the error discussed in the essay are mainly concern constructors’ fault. Traditional method to control error happen is focus on engineering supervision. Better management and more training could help constructors reduce the fault, but it is impossible to ask constructors keep all construction code in mind. Some new methods are needed.

Research on construction error

In this chapter I try to analysis common construction error happen in 6 structure types, summarize the reason and characteristic. Since the construction process is complex, here I just list the most significant error.

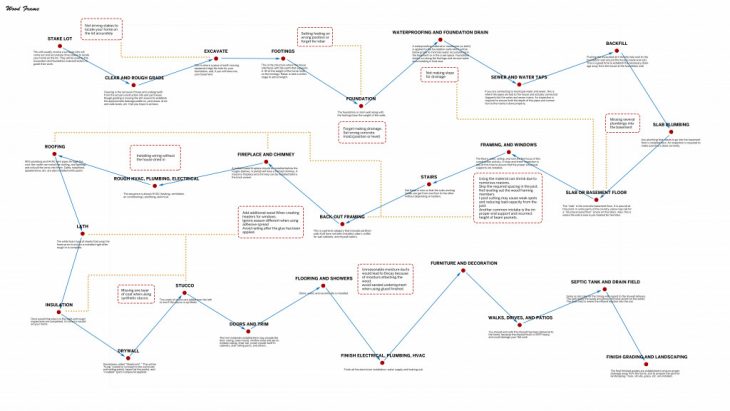

Wood frame

Foundation construction is the first step, if any error occurs at this stage, the whole process would be affected. The common mistakes contain driving stakes the lot accurately, setting footing on wrong position, or forget making drainage. When building the main part like floors, ceiling and roof, the possible errors are, using shrink material, skip required spacing in the joist, not leveling out the wood framing members, etc. Potential errors after the main part finish could be, install wiring without the house dried in, missing on layer of coat when using synthetic stucco.

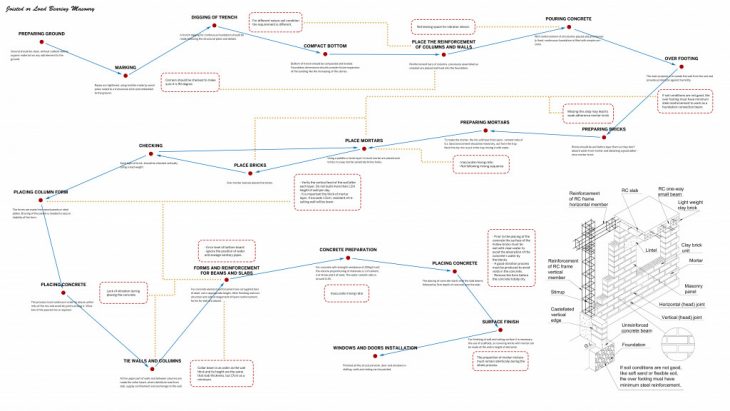

Joisted on load bean masonry structure

Like wood frame, more attention should be paid more during foundation construction to prevent errors happen. Corners should be checked to make sure it is 90 degrees. When digging trench, for different nature soil condition the requirement is different. A high probability error during placing reinforcement of columns and walls is not leaving space for vibrator device. When doing over footing, the soil condition should be taken into consideration. The over footing must have minimum steel reinforcement to work as a foundation connection beam if the soil condition is not good. The columns are always made by concrete. when placing concrete, vibration is necessary to help the concrete release air. Missing this step will make the column not strong enough to bear default load.

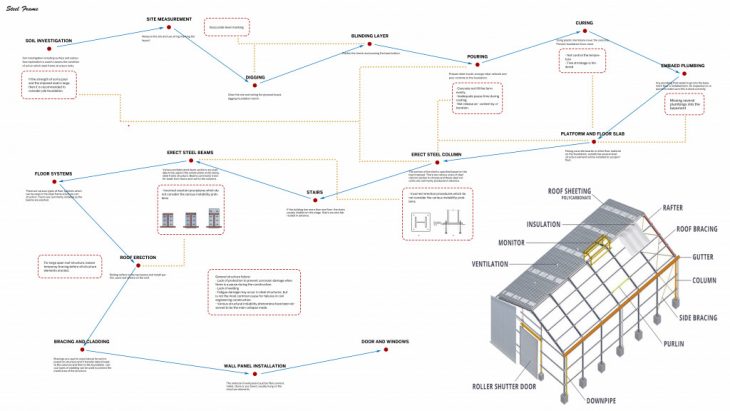

Steel frame structure

Compared with other structure, most elements of steel frame are prefabricated. The main mission on site is combine all the elements together. The probability of errors occur is lower, but still there are some things to note. The soil of site should be investigated first. If the strength of soil is poor and the imposed load is large, pile foundation should be considered. When pouring concrete to steel mould, concrete should be filled the form evenly, and the pause time during casting should follow construction code and according to environment. For large span roof structure, loosen temporary bracing before all structure elements erected is very dangerous. If there is a pause during construction, lack of protection may lead to corrosion damage.

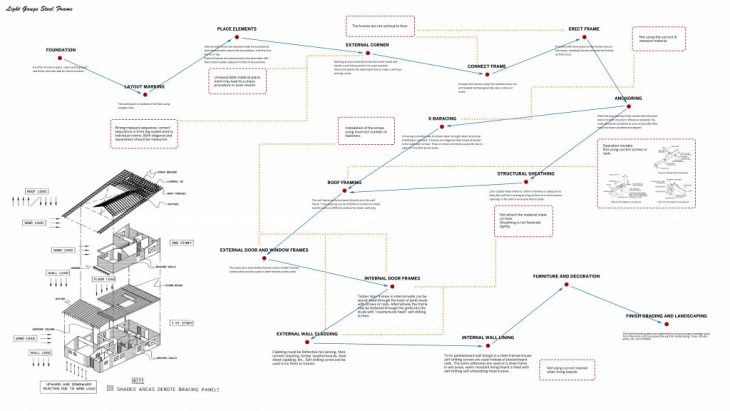

Light gauge steel frame structure

Foundation is always the first step to concern. During layout making, the measurement should follow the correct sequence. From big scaled area to individual rooms. Both diagonal and squareness should be measured. Like steel frame structure, light gauge steel frame has lots of prefabricated elements as well. So, a reasonable material placement is required, otherwise there might be a chaos procedure or even rework. When erecting frames, a potential error is not using the correct dimension material. Structural sheathing is an important step to keep the wall from racking if there is not excessive opening in the wall or excessive lateral loads. But the material sheet should be attached on time, otherwise it does not work.

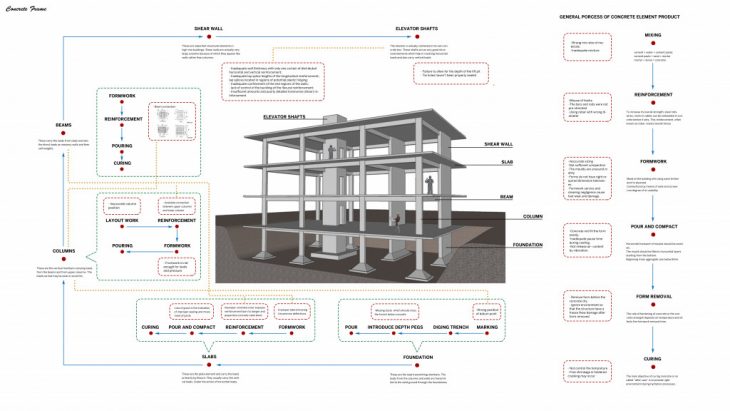

Concrete frame structure

As most common structure type, concrete frame has a rich construction code and technical details to follow. General process on concrete elements product contain six steps, mixing, reinforcement, formwork, pour and compact, form removal, curing. The potential mistakes could be wrong mix ratio of materials when mixing. When doing reinforcement, misuse of hooks and lack of pre-stretch for bars and rods would be a problem. Living tolerance for the formwork and keep them clean. When pouring, the concrete should fill the form evenly. Before remove the form, constructors should make sure the concrete is dry and check environment. Ignore environment may lead to the structure have a freeze thaw damage after form removed. Then control the temperature for concrete curing.

The whole construction is from bottom to top. Start from foundation, mistakes could happen in this stage is missing ducts which should cross the trench below concrete when introduce depth pegs. When making slabs, improper lateral bracing is a problem and pay attention to uncommon deflection. For column making, if the reinforcement connections between upper columns and lower columns are unstable, the whole building is in danger. Besides, the formwork should be enough for loads and pressure. Shear walls are important structural elements to bear loads. So, the buckling of flexural reinforcement should be controlled. When making elevator shafts, a stupid mistake is forgetting the depth of lift pit.

Classify errors

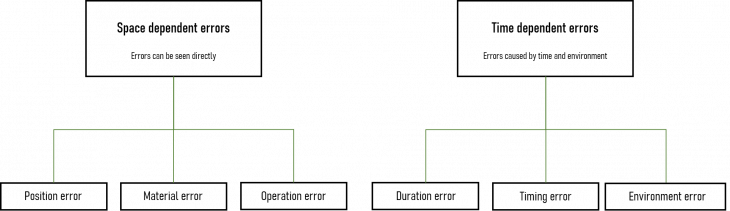

Even though construction is a complex process with huge operating steps, all these errors can be classified into two categories, space dependent error and time dependent error. Space dependent error people can see directly, like placing rebar on an incorrect position when doing reinforcement, combine steel beam and column in an inadequate way, or using wrong dimension screws when fasten elements. Time dependent errors are usually not caused by constructors’ activities themselves, but the time they do. For example, when making concrete, remove formwork before the concrete dry, the time is changing depend on environment; when doing structural sheathing, if material sheet cannot be attached on time, the protection will not work; when mixing concrete, there should be enough stir time.

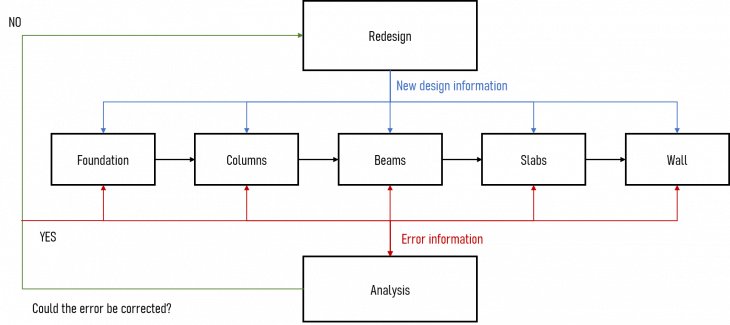

Chain reaction of errors

Constructions errors are seldom existing individually, especially those appear in early stage. If a mark made in measurement stage is incorrect, the foundation would have a wrong size, then the column might be placed on a wrong position. Which means the beam and slab size are cannot match columns. The whole construction should be redo. A small error may lead to a terrible result, that is chain reaction. A huge amount of wealth and material could be wasted. Even just not accurate enough at beginning, the error could accumulate step by step and finally show a big mistake. That is why making the work as accurate as possible from the beginning is extremely enough during construction process.

Remedial measure for construction error

Le Corbusier compared house to machine for living. If a machine does not work, people can simply use a new part to replace the damage one. But not all the error in the building can be fixed. For steel element combination, if constructors using a screw with wrong size, just take it of and use a correct can fix the error. But if a concrete column was placed in a wrong position, change it to the correct position is almost impossible. For irreversible error, the best solution is finding a reasonable way changing the design to adapt the error. A brilliant solution could be like a flower on the hole of clothes.

State of Art

Traditional methods to control error

Every country or region has their building code as a guidance for construction with dozens of books and thousands of lines. These codes could be considered as experience summary, which contribute a lot to control errors. But it is impossible for all constructors to keep all these lines during there work. Lack of skill and carelessness is the majority reason for constructors make mistakes.

Traditional method focuses on management. Conscientious construction company could provide adequate training to their employees. A reasonable schedule can help constructors working systematically and reduce error happen. Management methods like responsibility and supervisor can help constructors concentrate on their work and discover error as early as possible. Positive action can reduce error occur. But it still relies on human’s willing to control the error.

Latest research with emerging technology

VR/AR is widely used to stimulate reality. A research team of University of Tasmania tried to use AR device to give the constructors a guidance while they are working. In their experiment, they let the volunteers wear the AR glass and built a wall with bricks. The constructors can see where the bricks supposed to be through glasses and put bricks on the correct position easily. But for real construction site, AR device itself is expensive and easily to be damaged. Besides, let constructor work with AR device for a long time may lead to health problems.

Another attempt with computer vision is from a research team of University of Stuttgart. The team try to use computer vision supervise 3D print process and detect error. They use a camera capturing the image of object and compare the shape with digital model. If the similarity is under the preset rate, the print will be regard as an error. Even though this research is not about construction, it provides a technical method to check if a process is accurate. This method can be introduced in construction field.

Conclusion and Assumption

With buildings’ scale become lager and the function become more complex, construction work become harder and easier to make mistakes. Traditional methods are not enough. Researchers are trying to use emerging technology to control construction error. Even though most research are still in lab stage, they have already shown a big potential. It is believable that construction error can be controlled significantly with technology.

To have a wide application, emerging technology should show its’ advantage compare with traditional methods. Here are some assumptions base on characters of construction errors and technical capacity. Before construction start, machine learning can be used on risk prediction based on existing data. Computer vision could help doing real time detection prevent space dependent errors happen or discover errors immediately. Variety sensors could help measure time to prevent time dependent errors. Once an error was discovered and a redesign is needed, AI has the potential to do it and modify digital model automatically.

Bibliography

Strategy to change, November 2015, GIRI (get it right initiative) https:// getitright.uk.com/

8 common construction mistakes, https:// www.letsbuild.com/ blog/construction-mistakes

Damage Control: 5 Ways to Manage Construction Mistakes, PlanGrid, May 23, 2019, https:// blog.plangrid.com/2019/05/5-ways-to-manage-construction-mistakes/

Construction Sequence, http:// woodbuildaz.com/services/client-services/construction-sequence/

Common Types of Wood Framing Mistakes, JUAN RODRIGUEZ, June 25, 2019, https:// www.thebalancesmb.com/how-to-avoid-these-framing-mistakes-845104

An introduction to light gauge steel, NSC, MAY 11, 2017, https:// www.newsteelconstruction.com/wp/an-introduction-to-light-gauge-steel/

CONCRETE FRAME STRUCTURES, http:// www.understandconstruction.com/concrete-frame-structures.html

REINFORCED CONCRETE FRAME CONSTRUCTION, Ahmet Yakut, Middle East Technical University, Turkey

A Comprehensive Guide on Concrete Frame Structure Building, https:// civilseek.com/frame-structure-building/

Building Foundations: A Step-By-Step Guide, Bruce Bendall, 28 Nov 2019, https:// www.homebuilding.co.uk/foundations-explained/

Concrete Floor Slab Construction Process, https:// theconstructor.org/concrete/concrete-floor-slab-construction/25628/

Concrete Grade Beam Construction Process, https:// theconstructor.org/concrete/grade-beam-construction-process/24513/

Reinforced Concrete Shear Walls, February 26, 2016, https:// www.fprimec.com/performance-of-reinforced-concrete-shear-walls/

Causes of Structural Failures with Steel Structures, Stålbyggnadskontroll AB, Stocksund, Sweden (formerly Adjunct Professor in Steel Construction, The Royal Institute of Technology KTH, Stockholm)

Holographic Construction, Gwyllim Jahn1(&), Cameron Newnham1, Nick van den Berg, Melissa Iraheta, and Jackson Wells, Fologram, University of Tasmania, Launceston, TAS, Australia

Vision based error detection for 3D printing processes, Felix Baumann and Dieter Roller, University of Stuttgart, IRIS, D-70569 Stuttgart, Germany

Construction Error – A Hidden but Serious problem is a project developed at IaaC, Institute for Advanced Architecture of Catalonia, developed at Master in Advanced Architecture 2019/20 by: Student: Hongyu wang Faculty: Jordi Vivaldi, Manuel Gausa